Efficient off-site modular building techniques may help avert the housing crisis that is looming across the UK. Chris Lloyd looks at how electrical enclosure manufacturers are poised to help

House prices are so high that most young people can only dream about buying their own home, while affordable rental options are also very limited.

The government is so concerned it has published a white paper entitled: Fixing our broken housing market, which suggests that we need to build something of the order of 250,000 new homes a year across the country.

The report acknowledges the enormity of such an undertaking and promises financial support, making public land available for modular construction or prefab projects, and putting pressure on banks to lend on modular schemes.

Prefabrication or modular methods of construction are now highly developed, particularly for industrial buildings. They are also used to build schools, colleges, flats, hostels, nursing homes etc and are fast before the de facto construction for housing. In fact, ‘style-aware’ buyers increasingly opt for a cool Scandinavian or European prefab.

While it is not always cheaper, it is far quicker and more reliable than traditional construction, where project delivery times are affected by skills shortages, the weather and other variables.

With modular construction, wall panels or entire walls are built in the controlled indoor environment of a factory, and then shipped to site along with prefabricated roofs and floors for assembly on site.

The walls are supplied complete with electrical fittings, plumbing and other services built into them.

Spelsberg was one of the first electrical enclosure manufactures to supply electrical enclosures for modular buildings and has the experience of many successful projects to call upon. Its products are regularly specified by modular building companies, in the UK, Germany and indeed around the world.

In a recent project Spelsberg BS1 and BS2 electrical enclosures were cast into the concrete building panels of the UK’s newest super-prison, HM Prison Berwyn, which opened in 2017.

Designed for rehabilitation and education rather than punishment and incarceration, the accommodation rooms – they are not called cells – are fitted with showers, toilets, computers, phones and other equipment that will aid study and allow contact to be maintained with family.

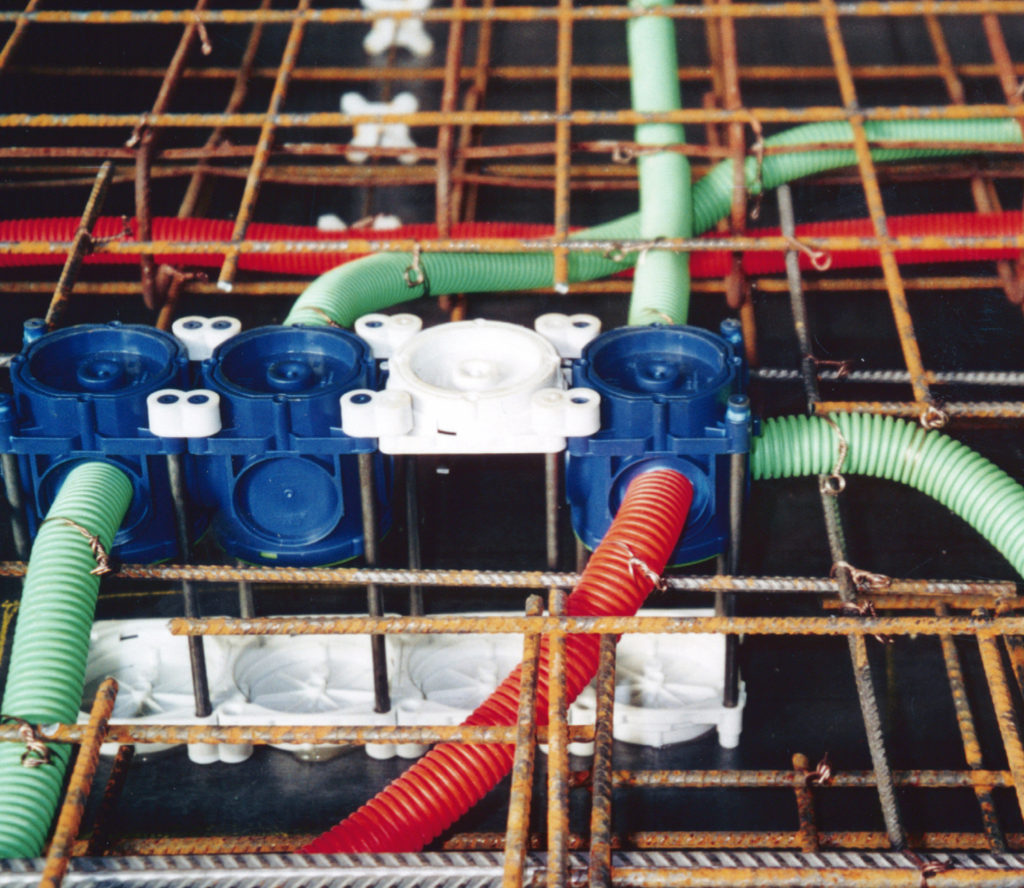

Built by Pre-Cast Concrete Structures Ltd (PCS), Berwyn used precast walls and floors incorporating services cast in for lighting, heating and drainage and coming complete with window and door frames.

Some walls also have cast into them Spelsberg BS1 electrical enclosures that provide sockets for power, TV and computers, while others have BS2 enclosures that house an intercom and call light so that the men can contact the staff should the need arise.

The BS series of enclosures is designed so that it is suitable for permanently casting into position in concrete panels. The requirements for two-way intercom and call light between the room interiors and the adjacent corridor or landing needed a special solution which Spelsberg solved by producing bespoke units for these, which are mounted with vandal-proof one-way screws.

Lesson learned at Berwyn will be applied to future prison building projects as the government progresses its programme of prison building to relieve overcrowding and modernise the estate.

Commercial and private properties are also benefitting from modular design and build systems.

For example, building companies know that fitting out bathrooms on site is time consuming and difficult to manage, so are increasingly turning to pre-built bathroom pods.

Spelsberg UK is helping pod builder Offsite Solutions develop ready to run electrical systems that can be connected up as soon as the pod is positioned in its host house, hostel or hotel.Offsite Solutions produce over 10,000 pods every year and appreciate the need for quality electrical enclosures, hence its partnership with Spelsberg UK, the country’s largest supplier of ex-stock non-metallic standard and customised enclosures.

All PODS manufactured by Offsite use Spelsberg customised and assembled TK units that are fitted with DIN rails, terminals or flying tails as required for specific pod designs. Offsite simply has to mount them into the pods and connect the external wiring.

Chris Lloyd is Managing Director of Spelsberg UK.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer