Nigel Thomas sets out the what the priorities will be for the manufacturing industry in 2020 and beyond

One of the most fascinating things about digital transformation is that it moves instantly – and slowly – all at the same time.

The trends we see on the horizon for Industry 4.0 in 2020 are much the same as trends that we’ve seen growing over the last few years.

The difference isn’t so much in the technology, it’s in the number of companies beginning to utilise it, and the reasons why.

The big question for 2020? Which technologies will warrant the investments required to navigate the digital landscape and accelerate the UK towards Industry 4.0?

Adopting automation

Next year, we will see a spike in the uptake of automation across the industry.

Repetitive, low-value tasks will be handled by software bots and machine learning – becoming more ‘intelligent’ as it learns the tasks along the way.

Automating in this way will redeploy valuable time, allowing humans to innovate and evolve skills as software supplements human intelligence.

As more traditional and routine tasks become automated, organisations are placing a premium on soft skills, from self-awareness to relationship management and communication, according to a recent report from the Capgemini Research Institute, Emotional Intelligence – the essential skillset for the age of AI

Embedding AR/VR

After years of maturing, we are finally seeing the deployment of AR/VR on the shop floor, and this looks set to continue. Manufactures have seen the value of these technologies in the simulation of the reconfiguring of factory floors or production lines and the simulation of working tasks.

Embedding AR/VR into manufacturing speeds up workforce training, ensuring more time is spent on the shop floor leading to increased productivity in a shorter time-span. With an aim to solve specific business problems. 2020 will see greater adoption of AR/VR.

AI will come naturally with enterprise applications

The megatrend for the next five years for the manufacturing industry is that of artificial intelligence (AI) being embedded in almost all enterprise apps.

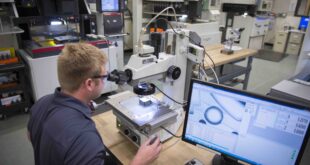

One of the main use cases of AI will be in computer vision: the ability of artificially intelligent systems to ‘see’ like humans – a subject of increasing interest and rigorous research for decades now.

With computer vision embedded in the machines, manufactures will be able to understand the working models of machinery and preferred setting for different workloads, among other uses.

Productivity takes centre stage

According to the Office of National Statistics, productivity in the UK fell at its fastest annual pace in five years in 2019.

Conscious of this, manufacturers are looking to adopt latest technologies like IIOT and automation to improve output. To make this possible, 2020 will see a rise in the use of cobots.

Working side by side with humans, cobots can complete complex or repetitive tasks, allowing highly skilled human workers to make use of the superior speed, strength and precision that cobots bring, allowing for greater efficiency and an increase in productivity on the shop floor.

Conclusion

In 2020, the manufacturing industry will continue to evolve, and digital transformation will touch every part of the value chain. From the shop floor to the factory, the adoption of digital capabilities to create business value will be critical to success.

Nigel Thomas is Head of Manufacturing, A&D, Automotive and Life Sciences at Capgemini.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer