We exist in a consumer driven world where product development and innovation moves rapidly. In the fight to keep pace, manufacturers can be tempted to compromise on quality and here, Graham Mackrell explains why companies need to be stringent and avoid cutting corners

The idea that all production has moved to China is a misguided view according to the Office for National Statistics.

In the UK, the demand for high-skilled production has gained much greater prominence in the past decade, especially when considering high precision manufacturing.

The issue for most manufacturers is the pressure of bringing products to market within constrained timeframes.

The pressure intensifies when the product is quality sensitive as is the case for precision manufacturing, and so the importance of employing the right gears for industrial equipment has never been greater.

Servo actuators and gears are vital components of industrial equipment used for steel manufacturing and in the machine tool industry. At Harmonic Drive UK, we’ve found that the significant growth in these industries has resulted in a surge in the demand for high precision strain wave gears.

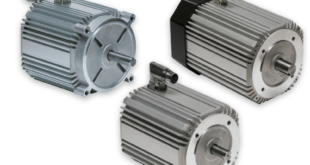

To meet the wide range of requirements for manufacturers, we have continuously developed our servo actuators in the LynxDrive Series.

Now, we have further extended the series to include the LynxDrive -25C, which is designed to be considerably more compact than traditional gear and servo motor combinations.

The LynxDrive -25C is a high precision strain wave gear with output bearing, combined with a permanent magnet servo motor that is specifically customised to the actuator.

Extremely robust and offering a high overload capability, the motor’s design, with its vacuum encapsulation winding, supports almost unlimited maximum performance, even at link voltages of 320VDC.

More importantly, the series is available in five sizes with six gear ratios between 30 and 160:1, providing accelerating torques between 50Nm and 176 Nm. This makes the servo actuators ideal for modern manufacturing machines that aim to reduce costs and increase productivity.

With high protection ratings and corrosion resistance, the series is perfectly suited for use in harsh and demanding environments like the industrial manufacturing plants of today.

With accurate positioning, Harmonic Drive’s actuator ensures stable machine characteristics and short cycle times without jeopardising quality.

Graham Mackrell is managing director of Harmonic Drive UK.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer