Based on a proprietary and patented crosslinking system that has been developed specifically for the chemical processing industry, DuPont Kalrez Spectrum 7275 seals exhibit minimal swelling and improved retention of physical properties when exposed to aggressive chemicals.

These include concentrated nitric acid, organosilanes, chlorosilanes, pure ethylene oxide, butyraldehyde, amines, vinyl monomers and acrylic monomers.

Kalrez 7275 seals are available in the UK from authorised distributor Dichtomatik Ltd.

Any process plant that uses chemicals as an inherent part of its operations knows the importance of reliable, long-lasting seal technology.

With Kalrez 7275, which is a special perfluoroelastomer product, users enjoy excellent compression set resistance and good retention of physical properties after ageing at high temperatures.

In fact, the seals will deliver a higher level of performance in any aggressive chemical processing application with temperatures up to 300°C, especially where high resistance to strong oxidisers such as nitric acid, chlorine and chlorine dioxide is required.

Among those able to vouch for the benefits of Kalrez 7275 is a paper mill in North America that relies on chlorine dioxide for its pulp bleaching operations.

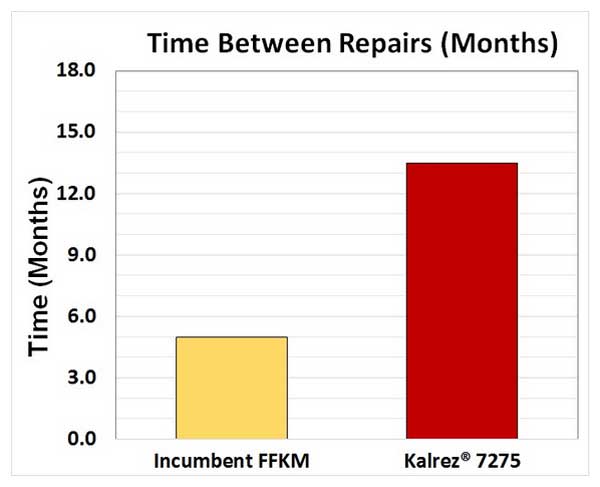

The paper mill was experiencing frequent failures of a pump handling chlorine dioxide in water.

According to the reliability engineer, the incumbent non-black FFKM seal typically failed within five months of installation because of the extremely aggressive nature of the stream.

However, following replacement of the seals with Kalrez 7275, seal life doubled to more than 12 months, removing the pump from the paper mill’s list of “bad performers” and into routine yearly maintenance.

Increasing the MTBR (mean time between repair) in this way contributes to reduced maintenance costs and longer equipment life, while improving process safety.

Aside from pumps, Kalrez 7275 will benefit many other applications which depend on mechanical seals as part of their critical processes, including valves, compressors, filtration columns and analytical equipment.

Uniquely identifiable by its light brown colour, Kalrez 7275 offers: a Shore hardness (A) of 75 (on the slab) and 81 Shore M (on the O Ring); 100% Modulus of 9.7MPa; tensile strength at break of 14.5MPa; elongation at break of 160%; and compression set of 22% (70 hours at 204°C). The product is available in a broad series of standard O-ring sizes and custom parts for a wide range of sealing applications.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer