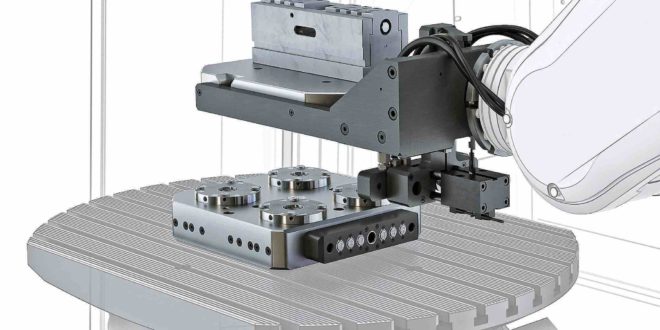

A robotic gripper with zero point clamping for automated pallet exchange on machining centre tables without their own media supply has been introduced by the Stark division of the Roemheld group. It is available in Britain and Ireland through subsidiary company Roemheld UK.

The services needed for clamping and releasing the workpiece, whether hydraulic, pneumatic or electrical, are all transferred to the clamping plate via a multiple coupling integrated into the robot’s pallet gripper.

The system is supplied to suit a user’s requirements and is a cost-effective, entry-level solution to automated production that may be retrofitted at any time.

Implementation is short owing to the system’s standardised coupling and flexible modularity. Process safety is assured by air blow removal of swarf and automatic checking of correct component seating, clamping and release.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer