Due to the current COVID-19 pandemic, production of ventilators has skyrocketed, in order to support the exponential increase in demand for patients infected with the novel coronavirus.

This demand exceeds the production capacity of typical ventilator manufacturers, and so manufacturers who usually produce other products have found themselves switching production over to meet the increase in ventilator demand.

Some of these manufacturers are already properly outfitted for ventilator production, but most have needed to adapt and add to their existing machinery.

Ventilator basics and meeting demand

A ventilator consists of several major components: oxygen sensors, pressure pumps, motors, and a battery pack.

Each of these consists of sub-components, and are typically manufactured separately and then combined before being shipped out to support patients in ICUs and other hospital settings.

Manufacturers already using advanced welding technologies are typically well poised to switch their production over to ventilators, because there is extensive welding demand in ventilator components.

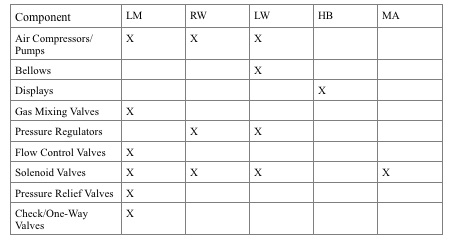

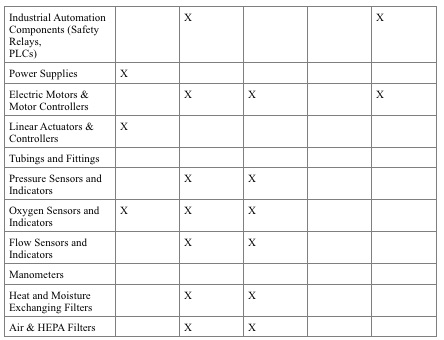

Below, find a table of ventilator components and the types of welding that are used to produce those components.

LM = Laser Marking; RW = Resistance Welding; LW = Laser Welding; HB = Hot Bar Bonding; MA = Micro Arc Welding

Given the importance of welding technology to nearly the full range of ventilator components, Amada Weld Tech provides manufacturers with additional welding technology to meet these unprecedented needs, as well as to provide support to existing customers who are looking for ways to adapt their existing technology to new applications.

Adaptation in order to facilitate rapid ventilator production is a critical component of response to the current pandemic, and superior welding technology, in particular, will be an important piece of this puzzle now and moving forward.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer