Industrial heating technology manufacturer Watlow has upgraded its Fluent heater, which now features dual voltage capabilities. The lightweight, high-performance solution reduces overall system cost and complexity of heating in semiconductor, medical and analytical industries.

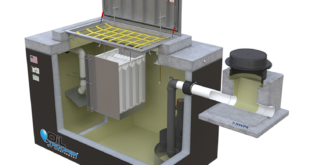

Watlow’s Fluent heater is a high watt density, low mass heater that enables on-demand fluid heating with an ultra-fast response, leading to higher system performance. The standard construction includes an internal baffle to promote turbulent flow and high efficiency, a fast-responding high watt density layered heater circuit, low profile axial lead exit and an internal thermocouple for high limit control.

Now, the popular heater has been upgraded with dual voltage capability, which allows heating products to accept more than one type of voltage. In traditional thermal systems, a unique design was required for each voltage to support global demand. But with a dual voltage Fluent heater, one design can deliver the same wattage level on both 120V and 240V systems.

This means the same heater can now be used in different regions to quickly and accurately heat liquids or gases as a single, integrated solution.

The Fluent heater is an in-line heating system, meaning engineers can easily integrate the heater by connecting tubing to the Fluent’s inlet and outlet. “In-line helps to save installation time compared to a traditional immersion heating solution and eliminates additional components — reducing overall system cost and complexity,” said Andy Selvy, chief system designer at Watlow.

“Other heating technologies require more components and therefore added weight and complexity, increasing the risk of breakdowns and more frequent maintenance intervals. The compact nature of the Fluent heater means the size and complexity of the heating system is decreased, without compromising on efficiency, performance or control. In fact, its smaller size reduces overall component weight by up to 95%, compared to both traditional circulation heaters and cast-in heaters.”

Running 240V wiring or installing step-down transformers to select locations can be a costly renovation project, and depending on a facility’s needs, this may also be time-consuming. “Instead, installing a heater with dual voltage capabilities can prevent costly facility upgrades, and provides original equipment manufacturers (OEMs) and design engineers with the versatile heating solutions they require, helping to streamline efficiency,” continued Selvy.

In addition, the Fluent heater is powered by Watlow’s patented thermal spray technology, which makes use of its entire surface to produce heat, delivering consistent and reliable thermal energy when required. “Despite the compact size of this in-line heater, it is capable of delivering heat with improved temperature uniformity across its entire surface, optimising heat transfer,” explained Selvy.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer