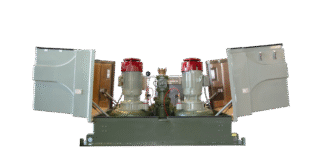

AMADA Weld Tech’s TR-T0016A Touch Retract Welding Torch is a hand-held and machine-mountable tool has been developed specifically for the welding of conductive thin-sheet metal. Ideal for the assembly of battery modules and packs, this torch provides consistent welding performance in an easy-to-use form.

One of the benefits of the TR-T0016A is its ability to allow battery makers to transition from nickel to copper tabs, ultimately improving battery performance by 20%. Though copper’s conductive nature makes it difficult to weld with resistance welding, the micro-arc welding enabled by the TR-T0016A provides a highly efficient means of generating localised heat.

The tool is suitable for welding multiple battery designs in a wide range of battery pack configurations. Specific applications of the TR-T0016A include the following: stainless steel 0.3mm to stainless steel 0.3mm, 0.3mm stainless steel to 0.1mm 9 carat gold plated stainless steel, 0.3mm copper tab to 18650 battery cells, and welding 0.3mm copper tab to battery cells.

This torch is also distinguished by its ease of use. The lightweight, ergonomic design lets operators easily manipulate the tool. Its protruding electrode and narrow, 7mm nozzle enable easy weld location control. The narrow nozzle also allows for a simple, repeatable weld location. Further, it can upscale manufacturing capacity with an integrated collar for machine integration.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer