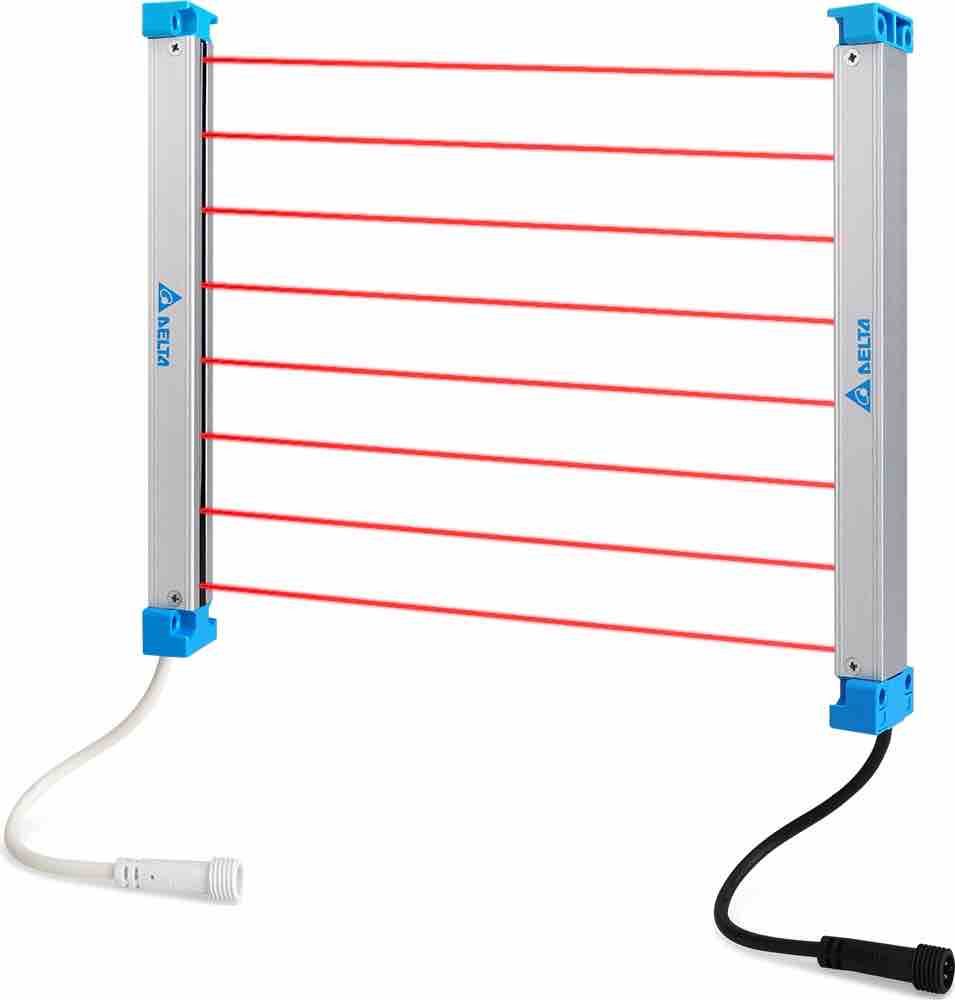

Delta has added two new area sensors – AS-E and AS-T – to its portfolio. The AS-E and AS-T models each sense a bigger part between the sensor lines, allowing them to detect and register products, ingredients and components. An example could be to identify an item falling from a conveyor belt or moved to an incorrect destination while being transported. This reduces losses and helps to minimise material wastage and transportation of wrong items. Both the standard AS-E area sensor and its more robust counterpart AS-T for outdoor use support comprehensive no-dead-zone detection within their working area. They are ideally suited for a diverse range of deployment scenarios in industrial applications.

The small form factor of the AS-E qualifies it for many industrial applications. Enclosed in a thin yet strong aluminium alloy case, it detects opaque objects larger than 30 mm over a range of up to 4 metres. The module can be front-mounted without the need for a bracket and its connector format enables simple wiring. The AS-E area sensor is an addition to existing sensor installations, such as those used in food and beverage production, packaging, medical technology, textile, rubber and plastics, warehousing, machine tools or the production of electronic components and equipment.

AS-T has been developed specifically for use outdoors. The area sensor is installed in a case made from thickened aluminium alloy, available in six different length sizes. The special design is based on a tubular waterproof mechanism that has undergone strict verification testing and is certified to the outdoor IP67 protection rating. In addition, the AS-T has a configurable NPN/PNP output, identifies objects as small as 3.4cm from a range of up to 3.6 metres, and is ideal for use as a detection sensor for outdoor door detection.

Martien Heesterbeek, Delta Product Manager, Industrial Automation Business Group at Delta Electronics EMEA region, explains, “With these AS-E and AS-T area sensors, we are offering our customers even more options for a diverse range of industrial applications. Both models help businesses to verify conveyed items even more quickly and accurately than before, thereby improving product quality for the long term.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer