What sets inventory management apart from stocktaking? How do they complement each other, and why combining both within a digital system can significantly improve accuracy, efficiency, and control in your warehouse, management and stocktaking processes

Efficient inventory control is the backbone of any successful warehouse, retail, or distribution operation. Yet many businesses still confuse two key processes: inventory management and stocktaking. While both deal with stock levels, they serve different purposes, follow different rhythms, and require distinct tools. Understanding the difference between the two is essential for optimising operations, avoiding costly errors, and ensuring compliance with financial and regulatory audits.

What is inventory management?

Inventory management is the continuous process of monitoring, controlling, and optimizing stock levels to ensure that the right products are available at the right time, in the right quantity, and in the right place. It encompasses a wide range of day-to-day operations, including receiving goods, storing them in designated locations, transferring items between storage areas, and managing order fulfillment. The primary goal of inventory management is to strike a balance between supply and demand—minimising excess stock that ties up capital while avoiding stockouts that can disrupt operations or sales. Modern inventory management relies heavily on digital tools such as barcode scanning, mobile apps, and ERP-integrated software solutions like COSYS, which provide real-time visibility into stock levels and streamline every movement within the warehouse.

What is stocktaking?

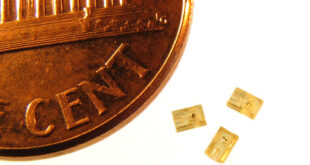

Stocktaking—also known as inventory counting—is the process of physically verifying the quantities and condition of items held in stock at a specific point in time. Unlike inventory management, which is an ongoing operational activity, stocktaking is typically performed periodically: annually, quarterly, or as needed for audits, compliance checks, or internal reviews. Its main purpose is to confirm whether the recorded inventory matches the actual stock on hand. Discrepancies uncovered during stocktaking—such as missing items, counting errors, or damaged goods—can point to problems in daily inventory processes, theft, or data inaccuracies. While it may be performed manually with checklists and spreadsheets, many businesses now use digital tools like COSYS stocktaking software to streamline the process, improve accuracy, and ensure that every item is traceable through barcode scanning, time-stamped entries, and user identification.

Key differences at a glance

- Purpose: Ongoing optimisation (inventory management) vs. verification (stocktaking).

- Frequency: Continuous (inventory) vs. periodic (stocktaking).

- Data Flow: Real-time updates vs. snapshot at a specific point.

- Personnel Involvement: Operational staff (inventory) vs. dedicated teams or audits (stocktaking)

How do the two work together

Inventory management and stocktaking are closely linked processes that, when properly coordinated, create a strong foundation for reliable warehouse operations. While inventory management handles the day-to-day tracking and movement of goods, stocktaking serves as a control mechanism to verify that the recorded data reflects the actual physical stock. Regular stocktaking uncovers discrepancies—such as losses, misplacements, or input errors—that inventory management systems can then address and correct. Conversely, an effective inventory management system can minimize the likelihood of such discrepancies in the first place. When both processes are integrated through a digital platform like COSYS, the synergy becomes even more powerful: real-time inventory tracking supports continuous accuracy, while periodic stocktakes provide validation and transparency. Together, they ensure not only operational efficiency but also audit readiness and compliance with industry regulations.

Tools that support both

COSYS offers two specialised software solutions that work seamlessly together while each focusing on a distinct aspect of warehouse operations: COSYS Inventory Management Software and COSYS Stocktaking Software.

Inventory management software

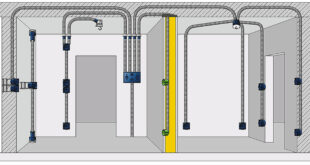

This solution is designed for the ongoing, day-to-day handling of stock movements. Employees use mobile devices or smartphones to scan barcodes and manage processes such as goods receipt, stock transfers, stock removal, and returns. All data is captured in real time and synchronized with the COSYS WebDesk, where managers can monitor stock levels, item locations, and warehouse performance. The system also supports minimum stock alerts, batch and serial number tracking, and full integration with ERP systems—giving businesses control and transparency over their entire inventory lifecycle.

Stocktaking software

Separate from daily inventory operations, the COSYS stocktaking Software is optimised for periodic physical inventory counts. It provides guided workflows for structured counting, supports offline scanning (with later synchronisation), and allows comments or photos to be added for damaged or unclear items. Each count is time-stamped and user-tagged, creating a secure audit trail for compliance and verification. Whether used for annual audits, cycle counts, or spontaneous checks, the stocktaking software helps ensure that actual stock matches recorded data—with minimal disruption to operations.

By using both COSYS solutions in tandem, companies benefit from a complete and robust inventory control system: one that ensures accurate daily operations and provides reliable verification through structured stocktaking.

Conclusion

Understanding the difference between inventory management and stocktaking is key to running a reliable and efficient warehouse operation — especially in sectors where precision and compliance are critical. While inventory management focuses on the continuous flow and control of goods, stocktaking provides the essential checkpoints to ensure accuracy and accountability. When both processes are supported by dedicated digital tools like COSYS Inventory Management and COSYS Stocktaking Software, businesses gain full transparency, reduce errors, and stay audit-ready. By combining real-time data with structured physical verification, COSYS empowers companies to confidently manage their stock — every day and at every count.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer