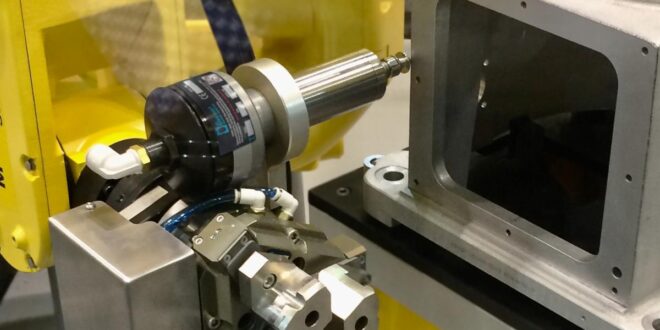

Air Turbine Technology‘s 450HD and 450XHD pneumatic motors are designed to deliver precision and durability at 25,000, 30,000 and 40,000RPM in demanding automated and robotic milling, deburring, drilling and finishing applications.

The 450HD and 450XHD only require a connection to 90 PSI (6.2 Bar) air, meaning there is no complicated setup, wiring or lubrication. Just drop the steel barrel of the 450HD into a fixture or toolholder on a robot, lathe or in an automated process.

All Air Turbine Motors feature a unique patented governor, which increases air flow to the turbine power producer to maintain rated high speed under cutting load. With this governor, high speeds can be achieved without sacrificing power.

With constant high-speed and torque sustained under load up to 40,000 RPM, and up to 1.4 HP in the double turbine 450XHD, the 450HD Series delivers 6 – 10X faster cycle times with no duty cycle limitations, supporting fully continuous 24/7 operation.

The constant high peripheral speed of the 450HD Series also ensures enhanced cutting tool performance, cleaner finishes and significantly longer tool life, making these motors ideal for milling, polishing, drilling plastics, routing, deburring and marking applications with tools up to ¼-in (6 mm) capacity.

Unlike other motors, Air Turbine Motors operate with only two moving parts, turbine and bearing sets. These generate low friction, negligible vibration and no heat. In addition, the heavy-duty grease packed bearings are cooled by turbine air. The result is precision and above all great durability with less repairs.

The 450HD Series weighs only 46oz (1.3kg) and has a vibration level under 1.25 m/s² r.m.s. Both models are sealed at the front end for wet or dusty environments and come with an ER11 collet system (1/4-in or 6mm capacity standard), collet wrenches, rear exhaust and a 3/8-in NPT air supply fitting. Air Turbine Motors run quietly, producing less than 78dBA during operation, contributing to a better working environment and compliance with occupational noise standards.

The single turbine 0.8HP 450HD requires a minimum 3/8-in (8 mm) internal diameter on air hoses and fittings and a connection to 90PSI (6.2Bar) air with 14 to 35CFM volume available on demand during operation. The double turbine 1.4HP 450XHD requires a minimum air hose internal diameter of 10mm to accommodate higher air consumption between 19 and 40CFM according to the load and weighs 48oz (1.36 kg).

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer