Viking Kristjansson sheds light on how outdated or poorly designed drainage systems are a major source of bacterial contamination and explains that upgrading to modern, sanitary drain designs can significantly improve hygiene, streamline cleaning, and support a proactive safety culture

The sanitation of floor drains too often receives little attention, falling victim to an out-of-sight, out-of mind mindset. Yet, neglecting them is a leading cause of food contamination at food production facilities. Relying solely on regulations and inspections is no longer enough to ensure safety, as government oversight has failed to keep pace with advancements in research.

Currently, the regulatory environment is marked by deregulation and a downsized inspection workforce, further widening the gap in oversight. This leaves businesses exposed to potentially devastating consequences. To safeguard public health and ensure safety, facilities need to shift from reactive compliance to proactive, preventative strategies.

Root cause of contamination

Poorly designed or hard-to-clean drains are the root cause of many food contamination incidents, with research consistently showing that over 80% of positive bacterial tests in plants can be traced back to drains and floor areas.

Harmful bacteria lurk within the drains or in cracks where the drains meet the surrounding floor. Once bacteria seep into the porous concrete, even strong disinfectants like bleach cannot completely eradicate them. The contamination can quickly spread throughout the facility, posing significant health risks and financial consequences.

Practical, cost-effective solutions

Fortunately, addressing these risks is not complex or expensive. Modern drain systems, designed to resist bacterial buildup and simplify maintenance, provide an effective and economical solution. These advanced systems enhance hygiene, reduce labor costs, and streamline cleaning processes, delivering a strong return on investment while safeguarding the facility.

Recognising drains as essential equipment

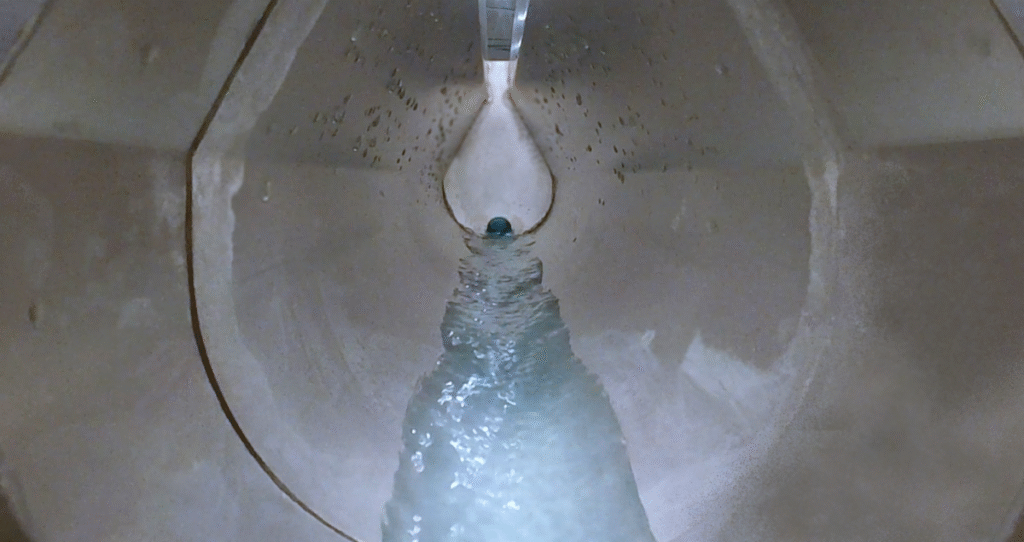

In food processing facilities, addressing the risks associated with floor drains requires a fundamental shift in perspective. Drains are prime breeding grounds for bacteria, providing dark, damp conditions perfect for microbial growth — akin to a laboratory cultivating cultures under ideal conditions.

To combat these risks, sanitary drains must be treated with the same level of importance as other critical equipment, such as food contact surfaces and conveyors. In a food processing environment, a drain is far more than just another structural feature like a wall or ceiling — it is essential equipment. When properly designed, installed and maintained, drains are vital to maintaining hygiene standards and ensuring smooth, efficient operations.

Food safety culture

In the food and beverage industry, there is growing recognition that building a strong food safety culture is essential to protecting consumers and achieving operational excellence. This culture must flow through every level of the organisation, from management to floor staff. Clean, well-maintained drains may seem like a small detail, but they symbolise an organisation’s commitment to safety and set the tone for a workplace where every employee understands their role in safeguarding food products.

A dirty, neglected drain sends a loud message: food safety is not a priority. These often-overlooked areas can undermine even the strongest training programs and policies. Employees notice these details, and if visible hygiene issues are ignored, it can weaken their commitment to maintaining a strong safety culture.

Selecting a drain system

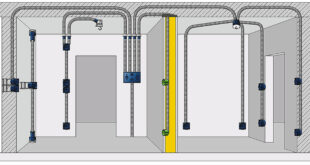

Selecting the right drainage system is crucial for ensuring cleanliness, efficiency, and food safety in production facilities. While traditional options like area drains and grated drains may meet basic requirements, modern slot drains are quickly becoming the preferred choice for contemporary facilities.

Slot drains offer significant advantages over traditional options. Unlike area drains, which require extensive underground piping, slot drains use far less, simplifying installation and maintenance. For example, in a 4,800-square-foot facility, an area drain system typically requires about 244 feet of buried pipes. In contrast, a 100-foot slot drain system can achieve the same drainage with just 10 feet of underground piping.

Another major benefit is the reduced complexity of floor design. Area drains demand a costly four-slope floor configuration around each individual drain, resulting in 48 separate slopes for the same facility. In comparison, slot drains require only four slopes for the entire linear system. This not only lowers construction costs but also creates smoother, more even floors, improving safety and efficiency for workers and equipment.

Slot drains also outperform grated drains. Heavy, cumbersome metal grates are not only difficult to clean but can harbor harmful microorganisms, posing hygiene risks. Slot drains eliminate the need for these grates, providing a streamlined, sanitary, and efficient solution that aligns with modern facility standards.

Effortless cleaning made simple

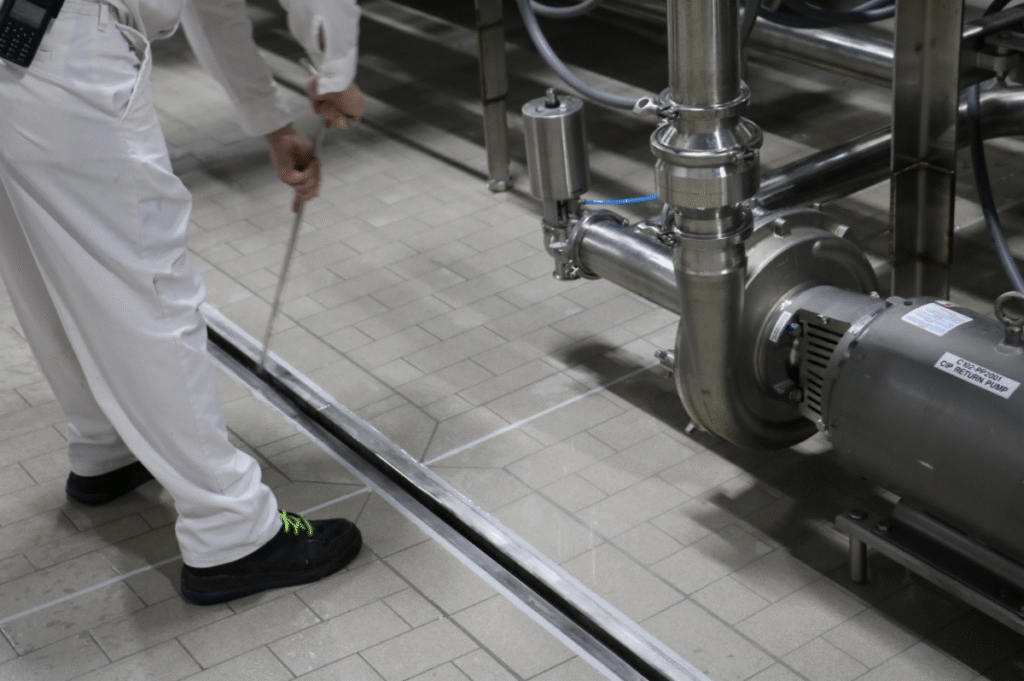

Modern slot drains are engineered for easy, effective cleaning, especially when paired with purpose-built tools that glide smoothly along the channel. However, not all slot drains are created equal. Many systems introduce cleaning challenges due to structural tabs every 18 inches or hard-to-reach corners that can trap bacteria and complicate maintenance. FoodSafe Drains, a leading provider of hygienic drainage solutions, has addressed these issues head-on with its seamless, tab-free Slot Drain system, purpose-built for the rigorous demands of food and beverage production environments.

FoodSafe’s Slot Drain Systems are constructed from corrosion-resistant T304 or T316 stainless steel, ensuring durability even under the heaviest forklift traffic and constant cleaning cycles. The no-niche, fully radiused interior design eliminates hidden crevices and sharp angles, making cleaning in place not only possible but highly efficient. The slotted linear trench opening facilitates rapid drainage while preventing clogging and standing water, key to maintaining high sanitary standards in busy facilities.

With NSF/ANSI/3-A certification and compliance with global food safety standards, FoodSafe Drains offers an innovative approach, including specialized cleaning tools and customisable configurations, to ensure that every aspect of drainage systems supports a proactive food safety culture. r organizations striving to build a culture of food safety at every level, partnering with companies like FoodSafe Drains provides the confidence that every aspect of the facility, including the most overlooked, meets the highest standards of excellence.

Floor drains are often the hidden weak link in food safety, yet their impact on contamination risk is profound. As research and industry experience show, poorly designed or inadequately maintained drains are a primary source of persistent pathogens, posing threats to both public health and a facility’s reputation. In today’s environment of evolving regulations and increased production demands, relying on outdated drainage systems or reactive cleaning protocols is no longer sufficient.

A proactive approach, one that recognizes drains as critical equipment and prioritizes their hygienic design, is essential for modern food and beverage facilities. Upgrading to advanced solutions, such as seamless, tab-free slot drains made from food-grade stainless steel, helps eliminate harborage points, streamlines cleaning, and supports a culture of safety throughout the organization.

By investing in state-of-the-art drainage systems like those offered by FoodSafe Drains, facilities not only reduce contamination risks but also demonstrate a commitment to operational excellence and consumer protection. Ultimately, the path to robust food safety starts from the ground up, with clean, efficient, and expertly engineered drains forming the foundation for safe, high-quality food production.

Viking Kristjansson is Vice President Sales Engineering at FoodSafe Drains.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer