Brushless DC (BLDC) flat motors are compact, but their small size means careful consideration over thermal management is required. As well as a focus on material selection, the operational characteristics and application environment are also crucial to specifying a BLDC flat motor. Vishal Sapale, explains the process of motor selection for effective thermal management

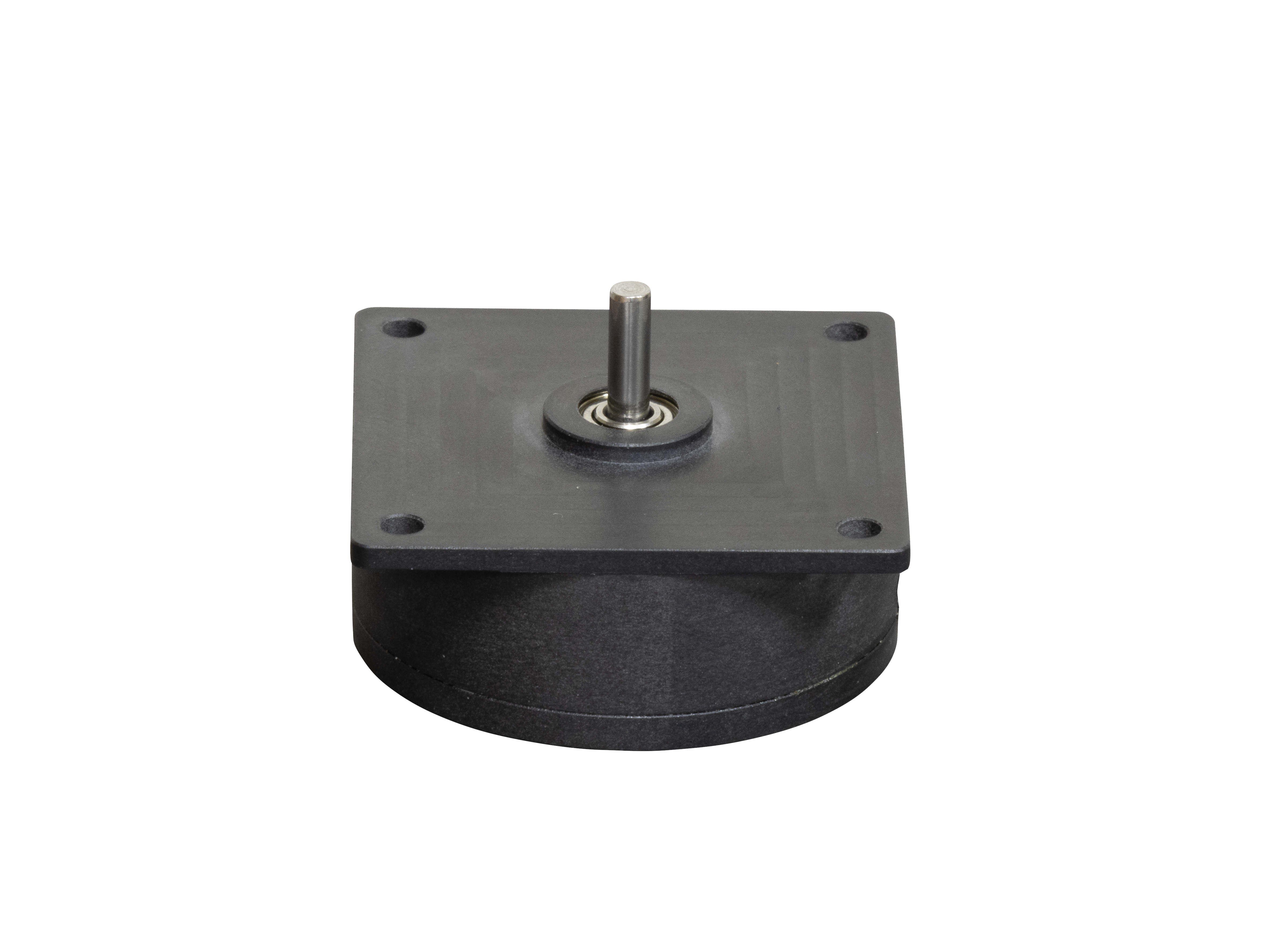

Flat Brushless DC (BLDC) motors, so called because of their form factor, are selected when small dimensions are essential and the high performance typical of BLDC motors is required. This makes them ideal for applications such as robotics, drones, tattoo machines, and medical devices.

However, despite their advantages, the inherent design of a BLDC flat motor, with a minimised surface area reducing heat dissipation, requires additional considerations to optimise thermal management. This is vital to optimise performance and efficiency and also to ensure reliability and a long service life.

Flat motor design

The compact dimensions and geometry of a flat motor play a crucial role in its thermal performance characteristics, yet extending surface area to improve heat dissipation will compromise one of the major benefits. To improve thermal management of the flat design, materials need to be assessed. Metals with high thermal conductivity, such as copper alloys, steel alloys, and aluminium, are ideal as they enhance heat dissipation, while materials with low thermal conductivity, like plastic and rubber, act as insulators and can trap heat.

Magnet quality also affects heat generation due to hysteresis losses, which occur when the magnetic core repeatedly magnetises and demagnetises, causing energy loss as heat due to material resistance. Samarium cobalt (SmCo) and aluminium nickel cobalt (Alnico) magnets achieve improved thermal stability compared to standard neodymium (NdFeB) magnets, though super-high (SH) and ultra-high (UH) grade NdFeB magnets can be used for high-temperature requirements.

Specifying thinner laminations in the stator core might be required to reduce eddy current losses. These circulating currents induced by changing magnetic fields cause resistive heating. If required, laminations manufactured from nickel and cobalt alloys can provide enhanced thermal stability compared to a typical silicon iron material.

Winding design also has a significant role, as increasing the number of turns adds to the length of the wire; this raises the resistance, causing further heat losses. Wire gauge and winding patterns also influence heat generation and dissipation, while the wire insulation material affects heat management. Resin or epoxy coatings can be applied to the windings to withstand thermal shock and improve thermal integrity.

Design elements may also be required, such as ventilation slots to enhance thermal performance. This can improve heat transfer from core components, while heat sinks and conductive materials further help passive cooling. Active cooling methods, including fans or forced air through tapered rotor slots, could also be integrated. In the compact footprint of a flat motor, minimising heat-causing friction between moving parts is also vital.

Operating conditions

Understanding the demands that will be placed on the motor during operation are also key to optimising thermal management. Higher loads result in increased current, leading to copper losses due to the resistance of the windings, so understanding the motor’s thermal limits under different load conditions is crucial for optimal performance.

The duty cycle also impacts the motor’s thermal behaviour. Motors with continuous operation or high duty cycles will typically generate higher temperatures, requiring more robust cooling features. Alternatively, applications that require dynamic control will generate high peak currents, also resulting in specific heat generation patterns.

Accordingly, speed affects heat generation due to increased windage and electrical losses. High-speed operation can affect cooling efficiency if the cooling mechanisms are not adequately designed, although for outer rotor motors, higher speed also helps with natural air convection and heat dissipation.

Environmental factors

The environment in which a flat motor operates is another crucial consideration. Higher ambient temperatures make it harder for the motor to cool down, increasing the dependency on design, as well as material and lubricant selection. This issue is compounded when heat radiation sources are present, and in these cases, effective heat shielding is required.

Humidity also impacts thermal performance by causing insulation breakdown and electrical short circuits. Moisture buildup can disrupt heat dissipation, reduce efficiency, and cause corrosion, so adequate sealing and moisture protection are crucial to maintain reliable operation.

Assembly and manufacturing

While materials and design features are crucial, subassembly and motor assembly processes also affect thermal performance. Due to the compact nature of miniature flat motors, high-precision tools and manufacturing processes are required to ensure that motor assembly achieves exacting tolerances. This ensures careful management of heat conduction as well as convection, and minimises heat-causing friction.

In high-performance applications involving BLDC flat motors, thermal management is a vital consideration. With appropriate specification, accompanied by precision engineered designs, reliable and durable BLDC flat motors can be provided, suitable for virtually any application and environment.

Vishal Sapale is a Portescap design engineer.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer