Recent updates to building codes now require high-rise elevators to be protected by high-capacity drainage systems that prevent flooding from sprinkler activation, a shift that signals the emergence of a new national safety standard. This article outlines how elevator drain technology not only meets evolving compliance mandates but also enables architects and engineers to safeguard elevators for first responders and occupants without compromising design aesthetics. Chad Kaatz reports

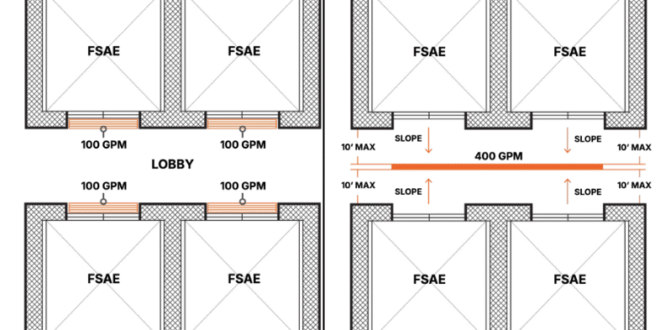

In 2023, New York City issued Technical Bulletin 2023-010, clarifying Section BC 3007.3 of its building code- a landmark update that reshaped how elevators in high rise buildings are protected during fire events. The legislation requires that Fire Service Access Elevators (FSAEs) and Occupant Evacuation Elevators (OEEs) be equipped with drainage systems capable of diverting at least 100 gallons of sprinkler discharge water per minute at each doorway. For buildings over 120 feet, this mandate ensures that elevators remain functional for firefighters and occupants even during active sprinkler operation. While the law is specific to New York City, it signals a shift in building codes that will inevitably extend to other major markets, setting a new national standard for elevator safety and design.

Why elevator drains are essential

Automatic sprinkler systems are indispensable in high rise fire safety, but the water they release must be properly managed. Historically, overflow was directed into elevator shafts and pumped out through sump systems. This approach introduced several risks: pumps can fail due to power loss or mechanical faults, shafts can flood before pumps activate, and maintenance requirements create additional liabilities. Most importantly, during an emergency, any interruption in elevator functionality endangers both first responders and occupants.

Elevator drains solve this by stopping water at the source. Installed either at the elevator threshold or in the lobby with sloped floors, these drains act as passive systems. With no moving parts, they require no external power and provide a continuous safeguard against water infiltration. In life safety design, passive systems are always favored because they eliminate points of failure and reliably function even under worst case conditions.

Evolving code requirements

Recent building code updates specify that elevators serving as either fire service access elevators (FSAEs) or occupant evacuation elevators (OEEs) must be protected against sprinkler discharge. The benchmark requirement is drainage capacity of at least 100 gallons per minute (GPM) per doorway. In practice, this means every designated elevator must be paired with a certified drainage solution capable of sustaining high flow rates.

Three approved methods are typically referenced: trench drains positioned at the threshold, pitched floors directing water to nearby drains, or site-specific designs based on sprinkler system discharge. All options must satisfy strict performance and accessibility criteria, including compliance with ADA heel-proof standards and third party flow testing.

Although the most prescriptive version of this rule originated in New York City, its logic is not confined to one jurisdiction. Insurance carriers, code officials, and design professionals recognize that keeping water out of shafts is common sense. California has already begun referencing similar provisions, and large urban markets such as Chicago, San Francisco, Los Angeles, Houston, and Dallas are moving in the same direction. History shows that when states like New York and California lead, others follow. Elevator drain requirements are no longer a regional anomaly — they are fast becoming a national standard.

Practical challenges for design and installation

While the intent of these codes is straightforward, implementation requires coordination across disciplines. Architects face the challenge of integrating drains into lobbies and elevator banks without disrupting the design aesthetic. High rise lobbies often feature premium finishes, and a large trench drain in the center of the floor can be visually intrusive. Narrow profile slot drains provide a streamlined alternative, with customizable grates and finishes that complement surrounding materials.

Global Drain Technologies emphasises design and aesthetics. Their slot drain systems feature narrow sight lines that nearly disappear into the floor, offering a discreet yet fully functional drainage solution. By tailoring drain styles, grates, and finishes to the needs of both luxury and standard buildings, they enable architects to maintain high design standards while meeting code. From custom powder-coated colors to sleek stainless steel, these drains integrate seamlessly into lobbies where every detail matters.

Structural engineers must also adapt. The edge of a concrete slab, the typical location for a threshold drain, is usually heavily reinforced. In both reinforced concrete and post-tension slab designs, rebar or cable trays need to be reoriented to accommodate drain placement. This adds complexity to the slab design but ensures the structural integrity of the building is maintained while meeting drainage requirements.

Mechanical and plumbing engineers are tasked with verifying performance. It is not enough to model drains for capacity; they must pass third party testing to confirm they can sustain 100 GPM for at least ten minutes under simulated sprinkler conditions. Certification through organizations like the International Association of Plumbing and Mechanical Officials (IAPMO) provides assurance that drains will perform as required. For contractors, adjustable grates and outlets are essential features. These allow drains to align with varying flooring depths and connect efficiently to plumbing within congested plenum spaces, simplifying installation and reducing costly adjustments.

Passive systems and the broader safety context

The shift from sump pumps to drains reflects a larger industry move toward passive safety measures. A drain requires no activation, no monitoring, and no maintenance beyond routine inspection. By contrast, pumps depend on power sources and mechanical reliability, both of which can fail during an emergency. Passive systems offer confidence that when water begins to flow, the system will automatically protect critical elevator infrastructure.

The stakes are high. Elevators designated for firefighter use provide direct access to all floors in high-rise buildings, enabling faster rescue and suppression efforts. Occupant evacuation elevators expand exit capacity during emergencies, reducing reliance on stairs and speeding the movement of large numbers of people. Ensuring these systems remain operational by protecting them from water infiltration is not just a compliance issue, it is a matter of life safety.

Preparing for tomorrow’s standards

As with many code changes, there is a learning curve. New requirements prompt a period of adjustment as architects, engineers, and contractors familiarise themselves with new products, installation methods, and design coordination needs. Yet the momentum is clear: elevator drainage is moving from a specialized concern to a mainstream expectation. The trend aligns with the building industry’s broader goals of resilience, safety, and future-proofing design.

Global Drain Technologies continues to push this evolution forward by designing drains that combine safety, performance, and aesthetics in equal measure. Their narrow, streamlined solutions prove that safety features do not have to be obtrusive. Custom options, from grate styles to finishes, allow building owners and architects to tailor solutions that elevate both form and function. In this way, elevator drains are not just a compliance measure but an extension of modern design principles.

Elevator drains may have entered the spotlight through regional code updates, but their significance extends well beyond one city or state. They exemplify how building codes evolve to close safety gaps exposed by past emergencies. For those involved in high rise construction, whether owners, architects, engineers, or contractors, the takeaway is clear. Drains are not a passing trend; they are the new benchmark for elevator safety.

By adopting advanced elevator drain solutions today, building professionals ensure compliance with current leading codes and prepare themselves for the standards that will soon define projects across the country. In doing so, they are not only meeting regulations but also safeguarding the lives of occupants and first responders, all while maintaining the design integrity that distinguishes modern buildings.

Chad Kaatz is Vice President of Engineering Global Drain Technologies (GDT).

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer