Allegro MicroSystems, Inc. announces the ACS37200, a galvanically isolated current sensor that provides a breakthrough solution to the efficiency and power density challenges in high-current applications.

As engineers design increasingly compact and powerful systems for hybrid and battery electric vehicles (HEV/EVs), industrial automation, AI data centres, and solar inverters, the heat and power loss generated by traditional shunt resistors has become a primary design bottleneck. The ACS37200, with its industry-leading 50µΩ conductor resistance, removes this obstacle, enabling designers to build smaller, more efficient, and more reliable power systems.

In a high-current system, every milliohm of resistance matters. A typical 100A design using a 0.5mΩ shunt resistor can waste up to 5 watts of power as pure heat, requiring costly and space-consuming heatsinks. The ACS37200’s ultra-low 50µΩ resistance reduces that power loss to just 0.5 watts — a 90% reduction. This means less energy is wasted and more power is available to drive the vehicle or run the server, directly improving HEV/EV range and lowering data center operating costs.

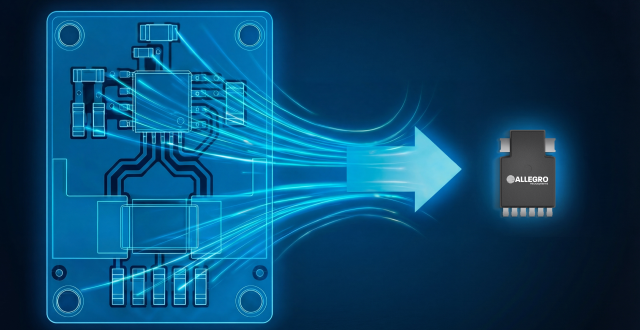

This efficiency gain is a critical enabler for power density. While Allegro’s previous generation of integrated sensors, such as the ACS772, already offered a nearly 7x size reduction over bulky discrete shunt solutions, the new ACS37200, in its compact 100 mm² PSOF package, takes this even further. It is nearly 70% smaller than the ACS772’s CB package, resulting in a total footprint that is 20 times smaller than a traditional shunt solution — a significant 95% reduction in board space. Because the sensor generates minimal heat, designers can eliminate bulky heatsinks, and its integrated architecture removes external isolation components, directly enabling this new level of compactness and higher power density.

Beyond efficiency and density, the fully integrated ACS37200 simplifies the design process. As a single factory-calibrated component certified to UL 62368-1, it replaces multiple discrete parts — including a shunt resistor, isolation amplifier, and associated passive components. This reduces the bill of materials (BOM), simplifies the supply chain, and removes the need for complex high-voltage isolation design, enhancing system safety and reliability.

Features and Benefits

- Ultra-Low Power Loss: Industry’s lowest conductor resistance of 50 µΩ reduces power loss by 90% compared to a typical 0.5mΩ shunt.

- Unprecedented Power Density: A 95% smaller footprint than discrete shunt solutions delivers more compact and cost-effective end products.

- Robust, Certified Isolation: Provides 1000 VRMS / 1,414 VDC of certified galvanic basic isolation in a single surface-mount package and is certified to UL 62368-1.

- Simplified Design: Replaces multiple discrete components (shunt, isolation amp) with a single factory-calibrated IC in a space-saving 8-pin PSOF package.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer