Cracked floors around drains are a common issue in food processing facilities, often leading to sanitation challenges, structural damage, and operational disruption. Viking Kristjansson explores the root causes of these failures and outlines a systems-based approach to floor and drain design, including material selection, construction techniques, and maintenance practices that can improve long-term durability and hygiene in food plant environments

Cracked floors around drains are one of the most common and troublesome maintenance and sanitation problems in food production facilities. These cracks are more than an eyesore; they compromise the floor’s structural integrity and create a breeding ground for contaminants that cause foodborne illnesses, costly product recalls, reputational harm, and disruptions to operations.

Once bacteria seep into porous concrete and cracks, even the strongest disinfectants struggle to eliminate them, as microbes burrow deep, linger, and eventually re-emerge, risking repeated contamination. Fortunately, these challenges can be fully addressed with a well-designed, modern drain system.

It begins with a robust drain design and solid construction, but true durability is achieved through a holistic approach that addresses all three major flooring components:

- The concrete itself

- The protective floor coating

- The drains integrated into the system

This coordinated method relies on custom-engineered hardware and superior installation techniques, creating a strong structural connection between concrete and drain as well as lasting, seamless adhesion between floor coating and drain components.

Drains represent the most vulnerable point in any food plant flooring, as they are regularly subjected to vibrations, impact, heavy rolling loads, and harsh fluids.

The impact of vibration and heavy loads

Forklifts, mechanised equipment, and daily operations place considerable stress on these systems. Most legacy drains flex under this pressure, which, over time, creates alternating cycles of tension and compression. When a drain flexes one direction, it pulls away from the surrounding flooring, forming gaps and cracks. Flex in the opposite direction, and it pushes against the surrounding concrete and coatings, leading to weakening and damage.

The effects of heat and chemicals

Another persistent threat to drains is aggressive cleaning regimens. Repeated use of hot water and harsh chemicals degrades both concrete and coatings. Extended temperature swings and chemical attacks erode the floor and break critical bonds, ultimately leading to cracks.

How do yo choose the right drain? Modern drain designs directly address these pain points through smarter engineering, stronger materials, and better floor integration. The process starts with picking the right drain for the application.

Why choose stainless steel

Stainless steel should be non-negotiable. Steer clear of outdated concrete trenches, they are inefficient and prone to delamination. Concrete’s porous nature traps bacteria, making effective sanitation nearly impossible.

Even for underground piping, stainless steel proves superior. While CPVC offers some durability, it cannot withstand severe heat. For instance, pouring boiling water into a stainless-steel drain leaves the drain intact, but CPVC pipes below may soften or collapse. To prevent this, opt for stainless steel piping underground, or at the very least, use it for the first 40-50 feet in hot water areas before transitioning to CPVC further down the line.

Picking the right drain type

Choosing the right drain for each area of a food processing plant is key to ensuring efficiency, safety, and hygiene. Different areas need specific drainage solutions, so understanding the options is essential.

The three primary drain types, area drains, grated trench drains, and slot drains, each bring distinct advantages and drawbacks.

Traditional area drains work well for small spaces but struggle in larger areas. They rely on extensive underground piping, increasing costs, complicating maintenance, and raising the risk of blockages and bacterial growth. For example, a 4,800-square-foot floor plan might require 244 feet of hidden piping with area drains. Another major issue is the need for floors to slope in four directions around each drain, making construction more challenging and resulting in uneven surfaces that hinder foot and wheeled traffic.

Grated trench drains once dominated but present their own concerns. Grates are heavy, awkward to clean, trap debris and bacteria, and are prone to chipping and corrosion. Additionally, they can be safety hazards for workers’ feet and equipment, as uneven or damaged grates can cause trips, slips, or entrapment of footwear, while wheels on carts or machinery may get caught, leading to accidents and damage.

Slot drains now lead the way in food sector upgrades. Their single, slender slot eliminates the need for grates, dramatically reducing places microbes can hide and vastly simplifying cleaning. Besides hygiene advantages, slot drains increase safety, enhance the visual appearance of a facility, and help foster a culture of cleanliness.

Resilience to load and vibration

One of the key advantages of slot drain design is its ability to minimise floor cracking by more effectively managing load and vibration.

Unlike traditional grated drains, the narrow profile of slot drains distributes weight and impact across the entire system, transferring more of the load from the drain to the surrounding floor. This design minimises stress on both the drain and its connection to the floor, providing enhanced durability and stability.

Additionally, slot drains also resolve common problems found in grated drains, like misaligned or damaged grates that can shift and bounce, increasing the wear and tear caused by heavy loads and movement.

Load class rating

Slot drains designed for heavy-duty applications, such as supporting forklift traffic in industrial environments, must adhere to strict load capacity standards. Typically, a minimum Load Class rating of E, capable of handling up to 550psi, is required.

Selecting drains with the correct load class is especially critical in areas exposed to heavy traffic, such as forklifts with hard pneumatic tires or heavy carts. Using drains not rated for these loads can result in flexing, which leads to delamination and cracking of the surrounding floor system.

Structural reinforcement

Structural strength is everything. High-quality slot drains incorporate advanced reinforcement features to withstand heavy loads and vibration.

- Angles: The strongest slot drains are reinforced with stainless steel angles. These angles add rigidity, preventing flexing and maintaining the drainage system’s strength.

- Embeds: Another critical feature is the use of steel embeds, metal components welded to the drain that tie into the floor’s rebar and are encased in concrete during pouring. This design solidifies the connection between the drain and the flooring substrate, creating a unified structural unit that resists shifting and ensures long-term stability.

Bonding floor coating and drain

Another important feature of advanced drain systems is that they are designed to ensure a tight and lasting bond between the floor coating and the metal drain.

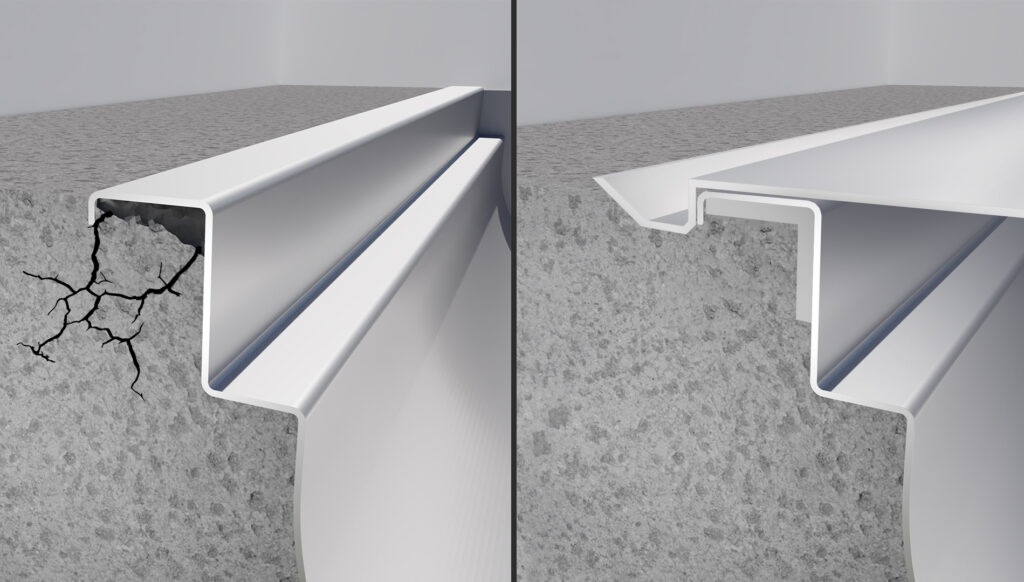

- Surface Area: Proper adhesion of the floor coating to the metal drain is achieved through a design featuring a lip that extends perpendicularly into the floor, significantly increasing the surface area for the coating to adhere to the metal drain. This ensures a strong and durable bond.

- Surface Preparation: The lip area undergoes specialised surface treatments, including primers and mechanical processes, to enhance adhesion. Since stainless steel’s chromium oxide layer naturally resists bonding, these proven methods are essential for achieving a permanent, seamless attachment between the floor coating and the stainless steel surface.

Cracks around drains often result from substandard installation practices. The following best practices can help avoid these issues:

Constructing the floor

- Slopes: Grade floors properly to prevent water pooling, extending the life of both the floor and coating while improving sanitation and reducing cleaning effort.

- Keyway: As shown in below, the keyway is crucial for proper installation. It is a groove in the concrete where the drain lip sits. If the keyway is too narrow to allow the floor coating to flow in during installation, the concrete will press directly against the lip of the drain. This creates a weak point where fluids can seep in, causing contamination. On the other hand, if the keyway is too wide, it compromises the structural integrity of the floor coating that will fill the space.

Installing floor coating

Proper installation of the floor coating is just as important as the floor construction. Pay attention to two key steps:

- Floor Preparation: The concrete substrate, including keyways, must be thoroughly cleaned and free of dust and debris to allow the floor coating to adhere properly.

- Priming: Both the concrete surface and the stainless steel lip of the drain system must be primed. This ensures the floor coating bonds effectively to both surfaces, providing a durable seal.

In addition to preparation and priming, one of the most frequent causes of premature floor failure is the application of insufficient coating thickness. While manufacturers specify minimum thicknesses for optimal performance, installers sometimes apply less material than required, whether to save on costs or due to time pressure. This shortcut can lead to weak spots, poor adhesion, and early delamination, especially in high-traffic or wet areas. To ensure long-term durability, project specifications should clearly state the required coating thickness, and quality control checks during installation should verify compliance.

Addressing these critical steps during installation significantly reduces the risk of cracks and ensures a long-lasting, reliable floor.

The importance of clear specifications

Many common floor and drain failures can be prevented at the design stage. Including detailed requirements for floor preparation, keyway dimensions, coating thickness, and drain selection in construction documents ensures that best practices are followed during installation. Early collaboration between engineers, architects, and installers is essential for long-term success.

Maintenance matters

A truly durable system relies on robust design, careful installation, and equally important, easy ongoing care. Advanced drain systems are designed to make cleaning extremely quick, easy, and effective, with accessories that simplify the process. Regular cleaning removes contaminants and prevents caustic substances from damaging floor coatings, protecting the facility and its operations.

Purpose-built cleaning tools have made maintaining slot drains more efficient. Paddle tools quickly clear debris, while brush tools provide a thorough scrub for detailed cleaning. High-performance tools, such as the Slot Dog from Food Safe Drains, a provider of hygienic drainage solutions, combine high-pressure water, foaming, and precision nozzles to effectively remove biofilms, grease, and tough residues. The Slot Dog is a specialised cleaning tool engineered for slot drains, featuring a flexible brush and integrated spray system that delivers targeted, high-pressure cleaning action along the entire drain length.

Well-designed slot drains provide an uninterrupted pathway, allowing cleaning tools to easily slide along the length of the drain. Unlike many drains on the market that feature obstructive tabs every 18 inches, trapping bacteria and complicating maintenance, advanced slot drains eliminate these barriers.

The Slot Hog from Food Safe Drains, a quick-connect funnel tool, goes a step further by allowing hoses to hook directly to the drain, efficiently directing large volumes of hot and caustic liquids into the drain without contact with the floor coating. This design effectively prevents harmful substances from flooding, pooling, or damaging floor coatings during processes such as CIP procedures or brewery tank cleanings.

A holistic approach to durable floors

A truly resilient and hygienic food plant floor is not the result of a single decision, but the outcome of a comprehensive strategy that brings together advanced materials, precise engineering, expert installation, and disciplined maintenance. The persistent problem of cracked floors around drains can be overcome by treating the floor system as critical infrastructure, worthy of the same attention as any other essential equipment in the facility. By prioritising robust stainless steel drain designs, specifying clear and enforceable requirements for floor preparation and installation, and committing to regular, effective cleaning with purpose-built tools, operators can break the cycle of recurring failures and costly repairs. This holistic approach safeguards the structural integrity and cleanliness of the facility and demonstrates a deep organisational commitment to food safety, operational excellence, and brand protection. In the end, investing in the right drainage system and best practices is not just about solving today’s maintenance headaches; it’s about building a foundation for long-term success, consumer trust, and a culture where food safety truly starts from the ground up.

Viking Kristjansson is Vice President Sales Engineering at Global Drain Technologies.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer