A new ASTM International standard will support the production of aluminium alloy parts via additive manufacturing.

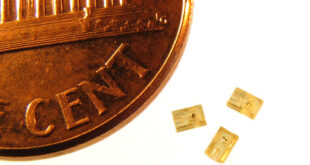

The new standard covers a certain type of additively manufactured parts (AlSi10Mg) produced using laser powder bed fusion (L-PBF) process.

Additive manufactured part procurement

This standard will help define a consistent set of requirements which both the user and producer agree to in support of additive manufactured part procurement activities.

“This new standard supports the standardisation of practice and advancement of commerce in the emerging additive manufacturing industry,” says ASTM International member Hector Sandoval, materials and processes engineer at Lockheed Martin Missiles and Fire Control. “Depending on customer requirements, parts may be used in a wide variety of applications, from prototyping to structural.”

The new standard (soon to be published as F3318) was developed by the committee on additive manufacturing technologies (F42).

3D printing

New standardisation work to support 3D printing is being driven in part by ASTM International’s new Center of Excellence in Additive Manufacturing, which expanded this week with a new partner: UK-based Manufacturing Technology Centre.

For more information, click HERE.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer