The obsession with protein has proved to be a lucrative one for dairies. Whether in snack or powder form, this popular supplement is extracted from whey, a by-product of cheesemaking, and it has developed into a lucrative revenue stream. One of the largest manufacturers of dairy products in Britain is improving the efficiency of protein capture with Bürkert’s FLOWave surface acoustic wave (SAW) flowmeter, which provides accurate measurement of solids in liquid whey.

The dairy processor extracts whey protein from its dairy production activities, which significantly reduces waste. This process is quite a recent phenomenon; many dairies used to dispose of thousands of tons of whey as a waste product. Now, they are producing protein that can be added to a range of products such as milk, shakes, puddings and yoghurt. With many people relying on protein supplements to improve their health, demand for these products is high.

A new process flow for dairies

The process involves recovering whey from milk using advanced separation technologies, producing liquid whey. This is then pasteurised and ultra filtered to make varying grades of whey protein. Thin and concentrated whey is blended to produce standard whey, which is then stored for later use. Efficiently extracting protein from whey relies on taking highly accurate protein concentration readings throughout the entire process. To measure this, dairies need to record the solid content in the liquid whey.

Traditionally, dairies have achieved this using Coriolis flow meters. These devices measure the mass and volume of the whey, then operators compare these data points to determine the protein content. While often assumed to be the best method, taking two readings and combining them takes time and compounds any inaccuracies. As dairies try to improve the efficiency of protein extraction for better profitability, these are serious limitations.

Shaking up protein measurement

One dairy was willing to take a different approach to protein measurement. The team worked with Bürkert UK, a leading manufacturer of measurement and control systems for liquids and gases, to trial its hygienic stainless steel FLOWave flowmeters in the process.

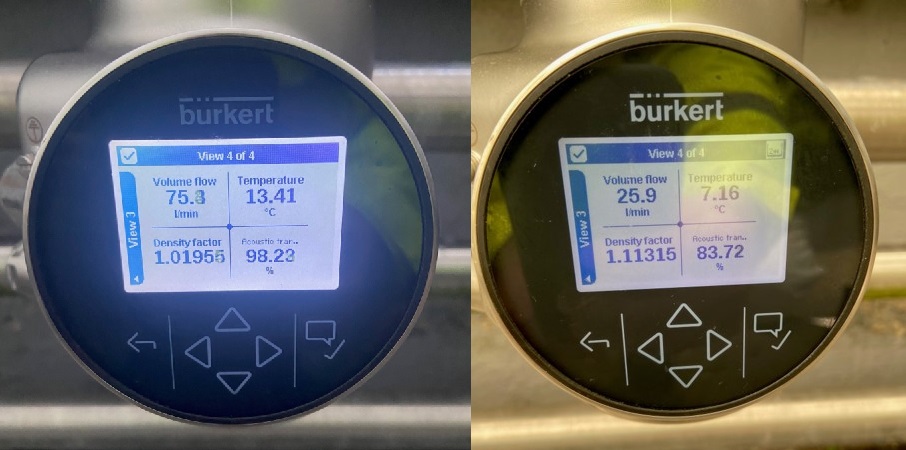

“FLOWave uses SAW technology to accurately measure solids, or protein, in whey,” says Kieran Bennett, Business Development Manager, Food & Beverage at Bürkert. “Using soundwaves passing through the whey, we can measure signal degradation as they encounter a solid – known as a reduction in the acoustic transmission factor. This allows the FLOWave to directly measure protein, providing an instantaneous, highly accurate reading. For context, it’s sensitive enough to detect minerals in treated tap water.”

Originally, the dairy processor was expecting to use a flow meter, a conductivity sensor and a temperature sensor on its whey protein line. As well as providing reliable measurements, the FLOWave is a multi-parameter sensor, providing all the aforementioned functionality in a single unit. In addition to saving space on the line, specifying the FLOWave in this application delivered at least a 40% cost saving compared to using a Coriolis alternative. It was also easier to install the FLOWave as its orientation does not affect its performance.

Accurate measurement of protein is of particular importance at many dairies, especially where sites are faced with challenges in whey storage capacity. Some operators have moved to a continuous extraction process that can reduce on-site storage requirements by up to two thirds.

“The FLOWave provides highly accurate solid content measurements in thin, concentrated and standard whey that are used to control the blending process. This continuous control and production of standard whey means only the finished product requires storage. The instantaneous readings from FLOWave following straining, filtration and blending play an important role in this innovative process,” adds Jon Roberts, Account Manager at Bürkert.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer