To truly realise the potential of additive manufacturing (AM), we need to embrace a new design philosophy, one that does not just work around variation, but works with it. Manolis Papastavrou and Laurence Coles make the case

For years, Design for Additive Manufacturing (DfAM) has been celebrated as a revolutionary discipline, one that empowers engineers to unlock geometric freedoms and create structures once deemed impossible. And indeed, today’s design and additive manufacturing ecosystem includes powerful tools that predict distortion, prevent build failures, and improve part quality through intelligent scanning and exposure strategies.

Yet, DfAM still only scratches the surface of what is possible. Too often, the industry remains fixated on the printability of a design with only minor modifications, rather than approaching the process with AM’s unique constraints and opportunities in mind.

This is a dangerous blind spot.

To truly realise the potential of AM, we need to embrace a new design philosophy, one that doesn’t just work around variation, but works with it. At Metamorphic, we call this approach “Designing for Deviation”.

The comfort zone of today’s DFAM

Most DfAM workflows today are rooted in a reactive mindset. A geometry is conceived, optimised for performance via tools such as topology optimisation, checked for support minimisation, and then sent to print. Too often, deviations (distortion, dimensional variation, surface inconsistencies, powder variability, and machine to machine variability) are treated as unwelcome surprises, only addressed afterwards through geometric offsets, rework, or redesign.

This is the engineering equivalent of filling in cracks in plaster with whatever you have to hand.

At Metamorphic, we take a different view. By understanding where deviation is most likely to occur, we intentionally position and shape critical features in regions and geometries less prone to error. In other words, we design with deviation in mind from the outset, not as a fix, but as a guiding principle.

By ignoring deviation until it manifests itself, the industry wastes time, money, and creative opportunity. Worse still, it narrows the scope of what is considered ‘possible’ in AM, because designers avoid pushing boundaries for fear of introducing unmanageable errors.

Why deviation matters

In traditional precision engineering, deviation is an unavoidable truth. Machining tolerances, thermal expansion, tool deflection, every process has its quirks. Skilled engineers factor these into their design thinking from day one.

In AM, however, deviation can be far more complex. Factors such as residual stress, scan strategy, heat accumulation, layer-by-layer distortion, and material microstructure all contribute to variation between the CAD model and the printed part.

Ignoring these realities during design leads to two recurring problems:

- Unpredictable performance. Parts may meet nominal specifications but fail in service because functional surfaces have shifted or stress states have changed.

- Scaling failures. A design that works beautifully for one-off builds may become unreliable or unrepeatable when moved to production volumes.

Designing for Deviation

Designing for Deviation flips the script. Rather than treating variation as an afterthought, it’s built into the design process from the start.

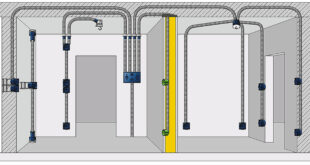

The entire sector needs to move towards a closed-loop approach, predicting likely deviations using simulation, empirical data, and in-situ monitoring feedback; integrating these insights into the computational design process, adjusting geometry and tolerances accordingly; and validating through iterative builds and inspection, refining the predictive model.

This loop is not a one-off exercise, it’s the heartbeat of advanced DfAM. By feeding real-world manufacturing feedback back into design, you stop chasing perfection on the screen and start engineering for reality.

Beyond ‘pretty geometry’

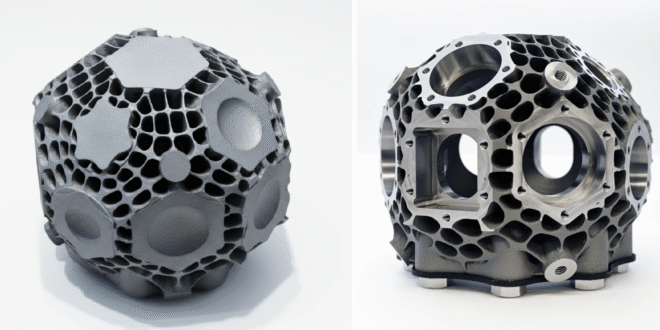

Too often, AM design celebrates complexity for complexity’s sake. Lattice-filled parts, organic surfaces, and biomimetic forms might look impressive, but without functional justification, they are little more than digital art.

Purposeful complexity, on the other hand, emerges from performance needs:

• Heat exchanger channel geometry with surface-based tabulators driven by CFD insights

• Viscous flow characteristics that shape internal channels in an inline mixer.

• Functional surfaces based on novel multi-physics informed design strategies

When you factor in deviation, form is not just adjusted after the fact, it is engineered from day one. Critical features are deliberately positioned in regions we know will experience lower deviation, while geometry types are selected to minimise the risk of distortion. Even build orientation and chamber dynamics (such as scan strategies or wiper blade direction) are considered in the earliest stages of design. In this way, deviation is not treated as an inconvenient afterthought but as a fundamental design parameter, shaping where features go and how they behave once built.

This is the real artistry of advanced DfAM. Performance-led geometry shaped by manufacturing realities.

The role of computational design and engineering intuition

There is a growing temptation to let algorithms run the show, through the combined use of generative design and machine learning.

But here is the truth, left unchecked, software will happily optimise a part into something that performs brilliantly in simulation yet fails miserably in its end-use application.

At Metamorphic, we see computational tools as collaborators, not controllers. We bring engineering intuition to the table, knowing which parameters matter, how processes behave, and how deviation manifests. This combination of human expertise and machine power enables us to produce geometries that not only push performance boundaries but also meet the practicalities of manufacture, inspection, and service.

The deviation challenge at scale

Prototyping in AM is relatively forgiving. You can tweak the design after each print, adjust parameters, and manually fix parts post-build. But the moment you try to scale to hundreds or thousands of units, that flexibility disappears.

Deviation at scale becomes a multiplier. A small distortion in a prototype might be acceptable. Repeat it across thousands of parts, and you have a catastrophic yield problem.

Designing for Deviation is the antidote. By anticipating and engineering out these effects before production begins, you ensure that your parts aren’t just manufacturable once, they’re manufacturable every time.

Where deviation design meets scalability

One of the biggest misconceptions in AM is that scalability will come from printing faster or buying more machines. In reality, the economic and throughput limitations of metal AM mean that for many applications, hybrid manufacturing is the real route to scale.

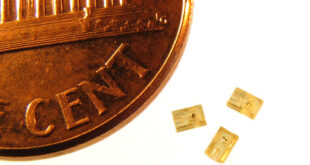

We have demonstrated how AM-derived designs can be adapted for processes, among others, like investment casting, without losing the performance benefits. This is where Designing for Deviation is particularly powerful, because transferring a geometry from AM to a traditional process introduces a whole new set of deviations to consider.

By designing with these in mind from the start, we can take a complex AM-optimised geometry and reproduce it faithfully in high-volume processes, bridging the gap between innovation and industrialisation.

Qualification is the last barrier

In regulated sectors such as aerospace, medical, and energy, qualification is often the highest hurdle. It’s not enough for a part to work, it must work consistently, predictably, and be certifiable.

Designing for Deviation accelerates this path. By reducing variation and controlling performance-critical features from the outset, you generate confidence not just in the design, but in the manufacturing process itself. Hybrid workflows add another advantage here: by moving into established production methods with known materials and inspection pathways, qualification becomes significantly faster, but only if you understand all the vagaries of a given process.

A new mindset for DFAM

To us, Designing for Deviation is not a niche idea, it is the logical next step in the evolution of AM. It’s about accepting that perfection exists only in CAD, and that the real measure of success is what comes out of the machine, not what’s on the screen.

The current state of DfAM is like standing at the shoreline of a vast ocean. The industry has been paddling in the shallows, focusing on printability tweaks and support reduction for years, while the deep waters of deviation-led design remain largely unexplored.

Those who dare to walk into deeper waters will find that deviation is not a constraint, it’s a creative catalyst. It forces us to think harder, design smarter, and ultimately build better.

Breaking the mould

At Metamorphic, we are not content with surface-level optimisation. Working closely with our partners, we aim to close the gap between design and manufacturing reality. But we do not stop there, we push further, redefining what Design for AM can achieve:

- Closing the loop between design intent and manufacturing outcomes.

- Treating deviation as a design input, not an afterthought.

- Harnessing computational power, guided by manufacturing rules, to steer geometries away from failure-prone regions and into robust, buildable domains

- Creating pathways from prototype to scalable, certifiable production.

This is how we move AM beyond incremental progress. Deviation is inevitable. Designing for it (proactively, intelligently, and in collaboration with manufacturing expertise) is a choice. For those willing to embrace it, the rewards are immense.

Manolis Papastavrou and Laurence Coles are Co-Founders of Metamorphic AM.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer