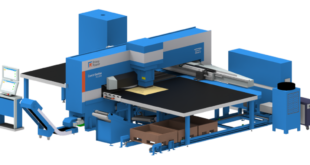

AM Solutions has announced the launch of its compact M1 system for automated surface finishing of 3D-printed parts in metal and polymer.

The new M1 replaces the previous M1 Basic and brings a host of new features aimed squarely at customers who want production-grade surfaces from a flexible, easy-to-integrate machine.

The new M1 combines smoothing, grinding, polishing, and deburring, in a single vibratory finishing platform. Parts up to 550×150×130mm can be processed as individual components or in small batches, with a clever divider system that allows up to three process steps to run in parallel without changing media, ideal for multi-stage finishing recipes.

Key upgrades include an additional fresh-water connection that enables processing with AM Solutions’ Keramo-Finish for exceptional surface quality, a redesigned processing trough with end-side profiling and extra partitions, and a new separation concept that shifts media/part separation onto a dedicated material cart for smoother workflow and higher throughput.

Despite the added capability, the M1 retains its compact, mobile footprint and plug-and-play philosophy. An integrated settling tank, modern HMI with intuitive menu navigation, and low noise levels make it easy to position alongside printers or within existing finishing cells. Users can choose to run in closed-loop process-water recirculation or fresh-water operation, depending on quality and productivity demands. Booth settings are fully automated and controlled by the machine and PLC.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer