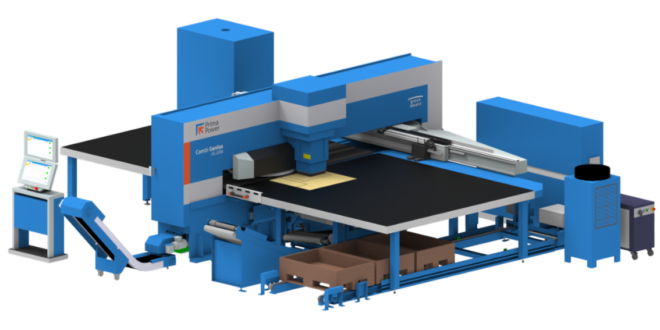

Prima Power‘s Combi Genius and Combi Sharp advanced punch-laser combination machines integrate high-speed punching and precise fiber laser cutting within a single, compact footprint.

The Combi Genius redefines flexibility, productivity, and efficiency for modern manufacturers. At its core is a high-capacity turret combined with IPG fiber laser resonators (3-, 4-, or 6-kW), enabling multiple operations, including punching, tapping, forming, marking, and laser cutting, in a single setup. This integration eliminates the need for multiple machines, reducing production time and optimizing floor space.

Both machines deliver rapid, high-quality cutting across a wide range of materials and thicknesses such as aluminum, mild steel, stainless steel, brass, and copper up to 8 mm. This allows manufacturers to quickly adapt to shifting production demands.

The modular design enables full customization and seamless integration with Prima Power’s automation solutions, including automated loading/unloading, material handling, part sorting, and storage systems. Supporting up to 400 tools, the Combi Genius reduces downtime and enables complex part production with improved material utilization. Intelligent ram technology with an optional rotating punching ram further shortens changeover times.

Automation solutions, such as the Compact Express, LST/LSR, and Night Train, streamline part sorting and reduce manual handling, enabling lights-out production and maximum throughput.

Energy efficiency is built in through servo-electric EcoPunch technology, delivering up to 82% energy savings, low maintenance, and high operational speed. This results in lower operating costs and a reduced environmental footprint. User-friendly software, including the Tulus® Suite, simplifies programming, monitoring, and production flow with intuitive interfaces, ERP integration, and real-time analytics.

Comprehensive life-cycle support, including process analysis, training, preventive maintenance, and remote care, ensures long-term performance and customer satisfaction.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer