Rapid and accurate detection of chlorine is vital to protect a (RO) system. While reagent-based approaches can be costly and impractical to manage, traditional amperometric chlorine electrodes do not respond fast enough when the most precise detection is required. Now, a study how RO system can be protected from trace levels of chlorine, as well as achieving and maintaining zero-chlorine conditions downstream. Greg Wainhouse reports

A reverse osmosis (RO) system removes dissolved impurities and contaminants from water by forcing it through a semi-permeable membrane. As such, an RO system can be crucial to the production of purified and ultra-purified water where the design is used across diverse applications such as pharmaceuticals, drinks production, as well as for healthcare procedures in hospital settings.

An RO membrane’s microscopic pores only allow water molecules to pass while rejecting dissolved salts, organic compounds, and various chemical contaminants, dependent on their size, charge, and chemical properties. However, a challenge to the membrane is chlorine exposure, which is typically present when feed water includes a mains water supply or disinfected borehole. RO membranes have a limited chlorine tolerance, usually rated at 1,000 parts per million of chlorine exposure over time, known as ppm-hours, and exceeding this will degrade the membrane and its filtration performance. As a result, precise and continuous chlorine monitoring upstream of the RO membrane is vital.

Protecting the RO membrane

Veolia Water Technologies Ireland produces purified water for the pharmaceutical and food and beverage sectors. At its Customer Experience and Life Science Centre of Excellence engineer training facility near Dublin, the site includes a granular activated carbon (GAC) filtration system, primarily installed to remove chlorine upstream of an RO membrane. The GAC filters are installed to dechlorinate the feed and protect the RO membranes. The vessels are periodically backwashed to remove accumulated particulates and maintain bed hydraulics; continuous chlorine monitoring is required to verify dechlorination performance and detect any chlorine breakthrough, particularly during operational upsets such as backwash and rinse.

Veolia reported that customer experience with techniques involving reagents is not a continuous measurement device and requires management of the reagent. The alternative traditional amperometric probes are maintenance intensive due to their inherent potential for drift, resulting from the manual approach to sample taking and analysis. While the test frequency required to achieve accurate and reliable results demands high costs in both reagent and operator time, a less frequent testing regime, such as testing on an hourly basis, is insufficient to achieve consistent results.

In contrast, a continuous online monitoring method delivers consistent readings to achieve precise analysis for effective membrane protection. To compare the effectiveness of technologies for online chlorine monitoring, identifying a precise and reliable system that was also easy to use and manage, Veolia commissioned fluid control specialist Bürkert.

Online water analysis

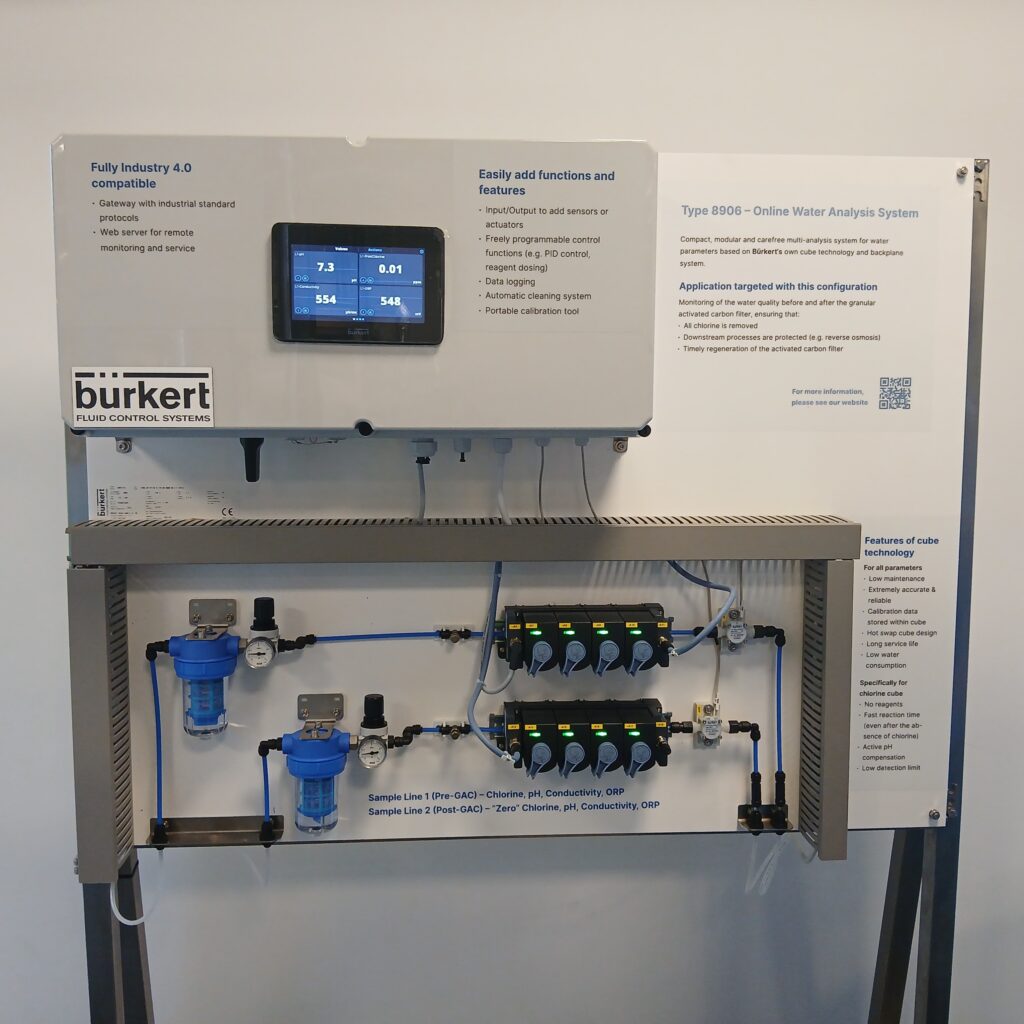

Bürkert provided Veolia with its Type 8906 Online Water Analysis System, equipped with an MS02 chlorine sensor and MS04 oxidation-reduction potential (ORP) sensor. The latter would provide an additional verification factor by identifying the presence of oxidising substances, including chlorine, which has an identification level around 650mV.

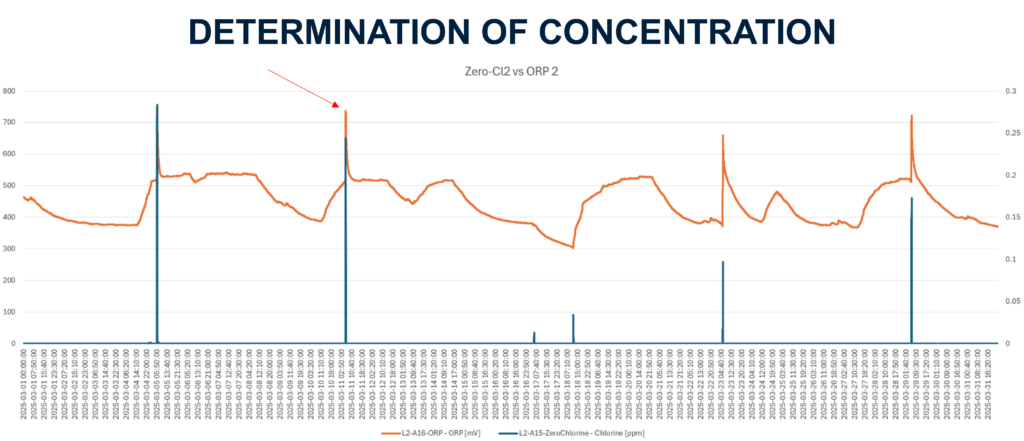

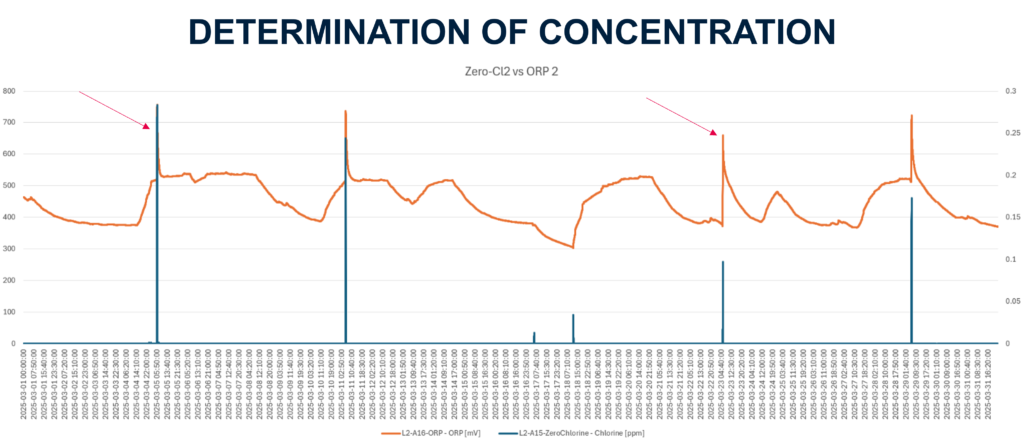

The trial would also compare the measurement precision of the cubes; an ORP sensor might be suitable for indication of oxidising species in the media, but they can also be affected by other elements. While ORP detects oxidising species, such as chlorine, it cannot confirm specific chlorine concentrations, crucial to determining chlorine contact hours on the membranes.

Veolia was also keen to test the efficacy of Bürkert’s MS02 chlorine sensor. While typical amperometric chlorine sensors have a T90 time of around 120 seconds, the duration that it takes the sensor to measure 90% of the chlorine concentration, Bürkert’s MS02 chlorine sensor has a much faster T90 time, reaching the total in less than 30 seconds. The MS02 achieves this rapid rate thanks to its specially designed single membrane protecting the MEMS sensor. Instead of a membrane pair surrounding an electrolyte pH buffer, which is the typical design, the single membrane means less resistance for the chlorine ions before sensor detection.

While most amperometric electrodes also require service and recalibration every three to four months, a more serious challenge is that post-GAC monitoring, the effect of polarisation means that this design cannot be used effectively. When chlorine is not present for prolonged periods, which can be expected following GAC filtration, the electrode surface can accumulate residual ions or film layers, and the sensor can lose its balance. As a result, when chlorine presence reappears, the sensor response is slow or doesn’t respond at all. However, thanks to an integrated electrode-block that provides an ongoing reference point, the MS02 does not suffer from polarisation, even after long periods without chlorine detection.

Results

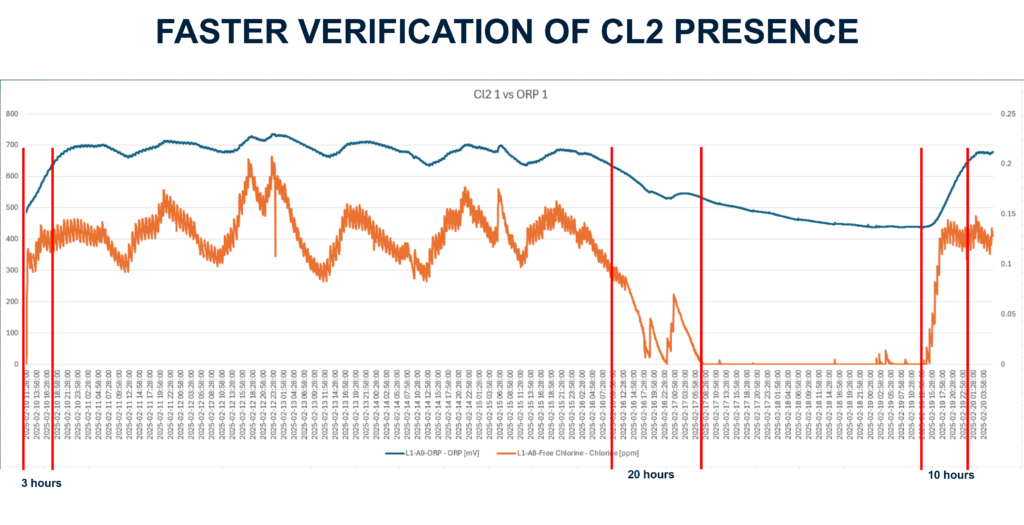

The study, which started in October 2024, first compared Bürkert’s MS02 chlorine sensor with the MS04 ORP sensor on the inlet to the GAC system, with higher chlorine levels expected prior to filtration. The chlorine sensor showed significantly faster detection of chlorine, with the ORP sensor failing to initially detect chlorine presence below 650mV for a three-hour period. This scenario repeated itself later in the study when detection wasn’t registered by the ORP sensor over a 20-hour period, where chlorine levels fluctuated between 0 and 300mV. While this represented relatively small quantities of chlorine, over time, it could still generate a volume sufficient to damage the RO membrane.

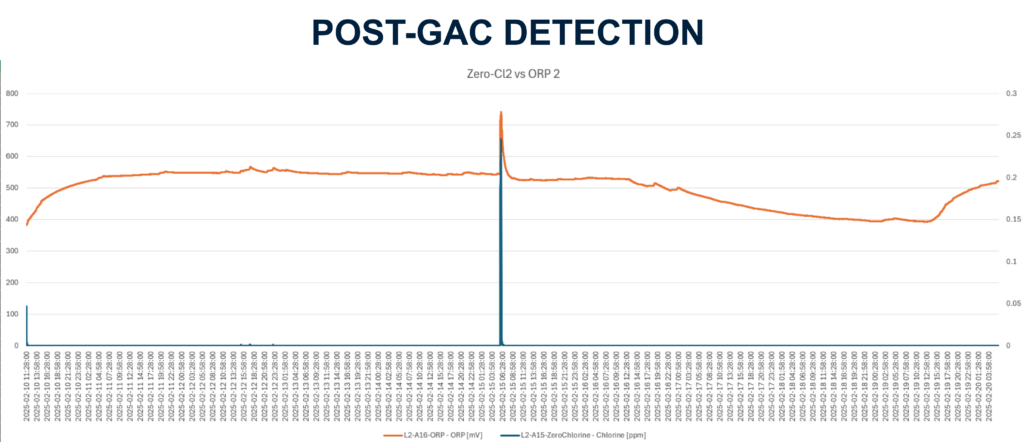

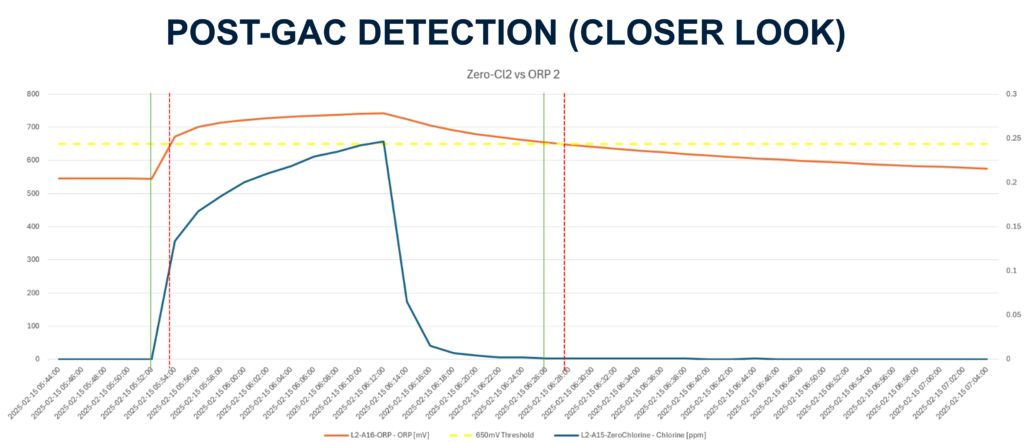

Monitoring chlorine levels downstream of the GAC system, a back wash caused some chlorine breakthrough, although Veolia was able to send this media to drain, preventing any attack of the RO membranes. Although total capture time difference between the two probe types was much closer compared to the inlet test, the results showed that if an ORP sensor had been used alone, the detection lag meant that chlorine would have penetrated to the RO membrane. If an electrodeionisation (EDI) system were in use instead of an RO membrane, even trace chlorine down to 0.05ppm could cause damage, emphasising the need for rapid detection.

Rapid detection and precise analysis

If chlorine is detected by the Type 8906 Online Water Analysis System, it can issue real time alerts, and visual alarms can also be set up to initiate an immediate response. The system also includes a 7-inch touchscreen to display live information, and records from the data logger can also be reviewed retrospectively for historical analysis.

As a result of the study, Veolia Water Technologies Ireland now has the potential to prevent virtually any chlorine traces entering the RO system, helping to achieve and maintain zero-chlorine conditions entering its customers’ RO systems. While establishing a much more robust system to protect the RO membranes, the approach is also saving significant cost and time compared to using traditional chlorine detection solutions.

“Bürkert recognised a real operational pain point for Veolia and translated it into a practical, technically sound monitoring solution that protects our RO membrane systems,” said Kieran Lyons, Project Director Ireland, Veolia Water Technologies.

Greg Wainhouse is Bürkert’s Regional Business Development Manager for Industrial Water, North Europe.

Image 1: Installation of the compact Online Water Analysis System was a simple process

Image 2: Bürkert’s Online Water Analysis offers precision monitoring of several parameters including chlorine, ORP, pH and temperature

Graph 1: Cl2 detection failures below 650mV by ORP methods due to slow reaction times, denoted by areas within red lines

Graph 2: Back wash of the GAC caused some Cl2 breakthrough

Graph 3: Graph shows that if ORP was the control, it would result in some Cl2 penetrating through to the RO membranes

Graph 4: Two similar ORP peaks but with different concentrations of Cl2, showing that determination of CI2 concentration with ORP is impossible

Graph 5: (As per graph 4). Two similar ORP peaks but with different concentrations of Cl2, showing that determination of CI2 concentration with ORP is impossible

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer