Flexible couplings play a key role in industrial drive systems. They connect motors, gearboxes and pumps, transmitting power while absorbing vibration and compensating for misalignment. When correctly specified, a coupling protects machinery from damage, reduces maintenance and supports long-term reliability. When poorly matched, however, it can instead increase wear, generate vibration and cause costly downtime.

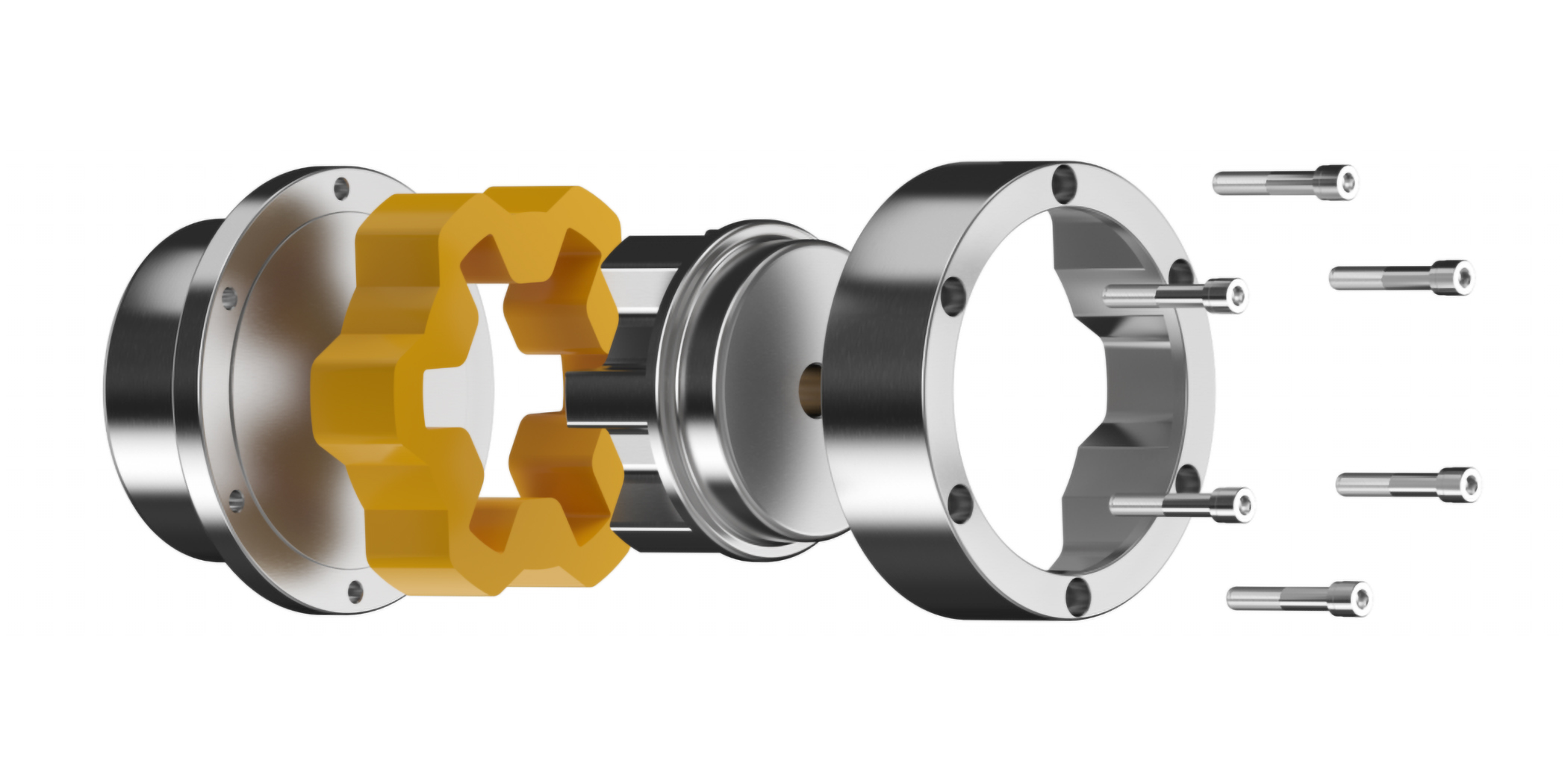

The Atra-Flex coupling from Tsubaki has been designed to meet these challenges by combining high torque capacity with superior flexibility. Capable of handling angular, parallel and axial misalignment, it helps preserve the integrity of connected equipment and maintain smooth, efficient power transmission, even in demanding environments.

Why misalignment matters

Achieving perfect alignment under real-world conditions is extremely rare. Foundations settle, bearings wear and temperature changes cause expansion, all of which create misalignment between the driving and driven shafts. Even small deviations can place additional stress on components, accelerate bearing wear and shorten service life.

As such, a coupling that can accommodate this movement is essential. The Atra-Flex design allows motion in all three planes without compromising torque performance, protecting connected shafts and bearings from excessive loads and extending the lifespan of the entire drive system.

Several features underpin the coupling’s performance and durability:

- Lubrication-free operation. Unlike conventional gear or grid couplings, Atra-Flex requires no grease or oil. Its elastomeric insert provides maintenance-free operation and removes the risk of lubricant contamination.

- Split-insert design. The insert can be replaced without moving the hubs or disturbing connected equipment, allowing fast maintenance and minimal downtime.

- Vibration and shock absorption. The elastomer element cushions torsional vibration and shock loads, protecting motors, gearboxes and driven machinery from stress.

- High torque capacity. Combining flexibility with strength, Atra-Flex is built for demanding industrial applications.

- Versatile performance. The coupling’s durability makes it suitable for sectors such as pulp and paper, mining, steel, water treatment and food processing.

Reducing cost through smarter specification

Selecting the right coupling involves more than matching bore sizes and torque ratings. Engineers must consider expected misalignment, accessibility for maintenance and potential contamination risks. In environments where frequent adjustment or lubrication are impractical, Atra-Flex can deliver tangible benefits.

Its maintenance-free design lengthens servicing intervals, while the replaceable insert simplifies upkeep. For applications where downtime is costly, these features can significantly improve overall productivity and total cost of ownership.

By combining strength, flexibility and easy maintenance, Atra-Flex provides a dependable solution for engineers seeking to minimise downtime and maximise efficiency. It offers a balance of performance and durability that supports productivity across a wide range of industrial applications.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer