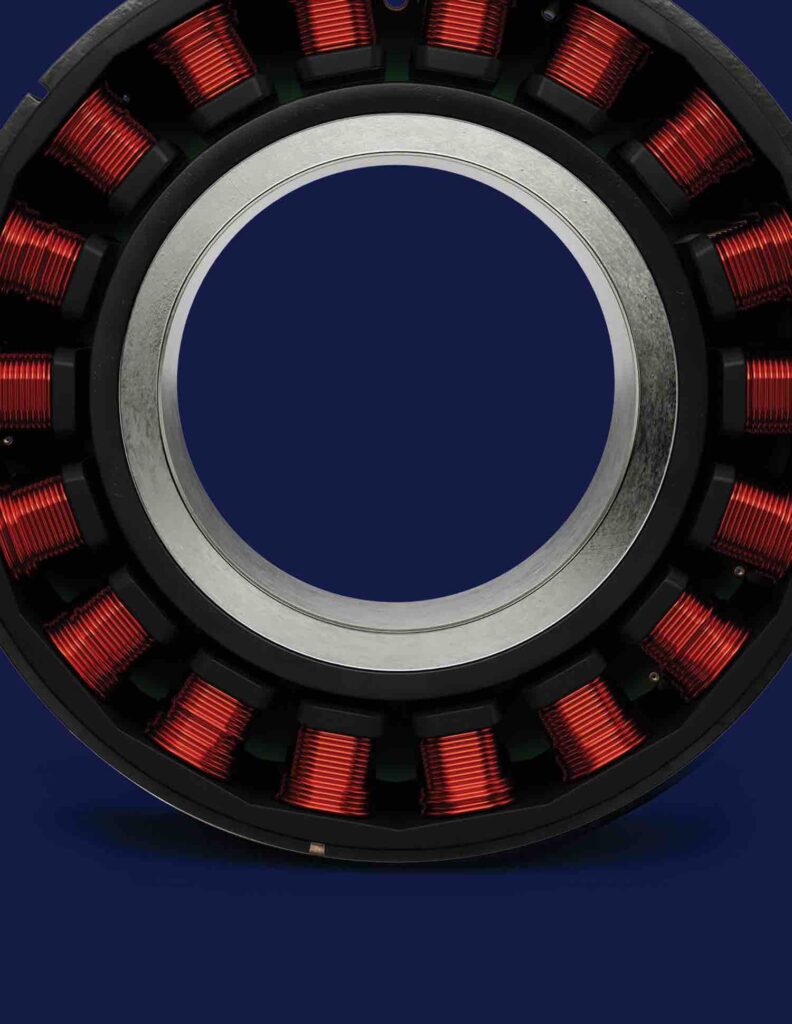

Kollmorgen has released a new range of frameless servo motors that increase speed and torque within a compact and lightweight footprint. The new TBM2G motors, distributed in the UK by INMOCO, are designed for cobot and similar robot joint control applications. The flexible range is available in a variety of frame sizes and winding types, and enables simple design integration thanks to their through-bore mounting design.

Optimised for operation at 48VDC and below, the TBM2G series provides high-performance torque in a compact footprint. The new design is aimed at helping OEMs develop robots with lower joint weight and higher load-carrying capacity, along with improved energy efficiency and lower thermal rise. The motors also ensure smooth movement thanks to their low-cogging design. Additional precision in control can also be increased with an optional integrated Hall sensor.

Frameless torque motors typically deliver their best performance at low speeds, with diminished torque at higher frequency. TBM2G motors remove this limitation through advanced windings and materials that deliver power, torque and efficiency consistently across a wide speed range.

The series is available in seven frame sizes, ranging from 50 mm up to 115mm. Each frame size is available in three stack lengths/winding options to meet precise speed and torque requirements.

The most compact motor in the TBM2G series delivers 0.27Nm continuous torque at stall at a rated speed of 8,000rpm, generating 0.205kW. The motor constant (torque divided by the square-root of resistive power losses), which shows relative output and efficiency to size, is 0.061 Nm/√W. The largest 115mm frame delivers 6.03Nm at 3,100 rpm, generating 1.43kW with a motor constant of 0.802Nm/√W.

The frameless design features a large inner diameter centre bore to accommodate encoders, cables, hoses, shafts, and tools. This enables easy integration of the motors directly into robotic joints, with typical applications including collaborative robots in the 3–15 kg range. For safety with cobot integration, the TBM2G motors are designed to perform at high speeds without exceeding the 80°C limit typically needed to safeguard humans working in proximity to cobots.

The new TBM2G motors complement Kollmorgen’s existing series of frameless motors, extending the speed and torque performance of the TBM range to enable a smaller footprint. The new TBM2G also offers a lower voltage alternative to the KBM that operates at 240V or 400V.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer