Cooling of power supply components is the key for ensuring reliable processes. CTX profile heat sinks are the chosen solution, especially in power electronics, which have to operate continuously and often under harsh conditions.

The company offers custom-tailored and project-specific solutions for thermal management of all power electronics applications.

In addition, CTX is the right choice to provide cooling solutions for power supply units, transducers, battery chargers, frequency converters, electric drives, and inverters. Which heat sink to use depends on the power dissipation and on the requirements of the particular device. Extruded profile heat sinks, cold forging heat sinks, and PCB board or SMD heat sinks for natural convection are typical options for robust and low-maintenance devices.

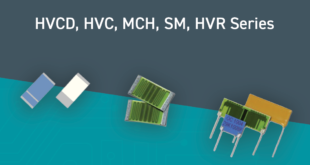

Aluminium profile heat sinks

Effective thermal dissipation through natural convection is achieved with aluminium profile heat sinks. This is made possible by the rib-like construction called fins, which results in a large overall heat sink surface area. Aluminium profile heat sinks are generally manufactured from an aluminium extruded alloy with a thermal conductivity of 200-220W/mK.

The CTX portfolio comprises both standard and project- or application-specific cooling solutions. The spectrum of standard extruded heat sinks includes fin, comb and finger heat sinks, as well as PCB-board heat sinks. Standard profile heat sinks range from 12.4mm to 750mm in width, with a weight between 130g/m and 75.1kgm and thermal resistance Rth between 81.6°C/W and 0.04°C/W.

On request, CTX will also perform post-CNC machining, based on customer drawings. The cooling specialist’s services likewise include professional surface treatment, like wet-painting, chrome plating, anodising, or powder coating. CTX also offers its customers labelling of their heat sinks by means of screen printing or laser engraving, as well as surface treatment by sandblasting or glass ball blasting.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer