Reliability is an essential component of the success of companies in the food and beverage industry. Endress+Hauser’s Teqwave H ensures the accurate and reliable measurement of sugar content in fruit juices and distilled beverages or the concentration of cleaning agents.

In its hygienic design, Teqwave H fulfills the highest quality standards with state-of-the-art algorithms and a flexible application concept for optimal process control, even for changing batches. Liquid analysis with Teqwave H allows users to reduce costs because it measures different concentrations simultaneously using only one sensor. In addition, preinstalled concentration data sets make using the same sensor without reprogramming possible. Teqwave H also allows reading additional parameters, such as acid content. Continuous inline measurement also means no sampling is required. Teqwave H’s full-bore design is easy to clean and guarantees the highest hygienic standards are fulfilled.

Furthermore, dispersion measurement is another advantage provided by Teqwave H. The typical appearance of disturbance variables such as particles and gas bubbles are reduced as Teqwave H directly measures, displays, and compensates for those disturbances and severity.

Concentration is crucial for product quality

Teqwave H can measure a wide range of variables, enabling it to be used flexibly in various applications. For example, in soft drink and fruit juice production, the measuring device assures product quality through its reliable determination of sugar and inverted sugar content. To produce distilled beverages, it ensures that the alcohol content remains consistent. In addition, it simultaneously measures the sugar content. When cleaning plants, bottles, and kegs, Teqwave H also monitors different concentrations and supports precise dosing of cleaning agents. If the cleaning agent needs to be changed, this can be done quickly without recalibration.

Hygienic design for the highest quality standards

Teqwave H is specially developed for hygienic applications in the food and beverage industry. Besides the stainless-steel measuring tube, its outstanding feature is its full-bore design. Thanks to the design without protruding parts, there are no places inside the measuring tube where material can accumulate. Another benefit is that there is no pressure loss, making it possible to save on energy costs.

Plug-and-play, thanks to preinstalled data sets

Teqwave H offers a wide variety of preinstalled product-specific data sets for concentration measurement, which allow the calibration usually repeated after the batch change to be omitted. In addition, the users can adapt these data sets to their product as needed to further increase the accuracy of concentration measurements. This means that users with a comprehensive product range need just one measuring device for a broad range of applications. This is particularly helpful when one production line is being used to manufacture the entire product range in various batches.

Function for gas bubble and particle detection

In many processes, dispersion typically occurs in the form of gas bubbles or particles that can interfere with the measuring signals. To support stable process control, Teqwave H enables users to detect such disturbance variables, evaluate their severity and compensate for them to achieve continuous accurate measurement. In addition, the device warns the user when the disturbance variables affect measuring accuracy. This guarantees maximum reliability and gives users even greater transparency in their processes.

• Continuous monitoring of disturbance variables directly in the process

• Immediate notice message if the disturbance variables affect measuring accuracy

• Reliable dispersion measurement; reacts exclusively to gas bubbles, particles, or two-phase mixtures (e.g., with emulsion formation)

• Targeted reaction to error signals in the production process, such as for contamination or leaks

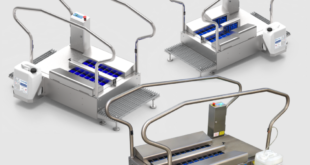

Transmitter for seamless system integration

Teqwave H is available with a transmitter in a remote version that can be optionally ordered with a stainless-steel protective housing. Teqwave H leaves nothing to be desired in terms of performance and accuracy. Teqwave simultaneously records multiple measured values essential for process control, such as concentrations, speed of sound, acoustic density, and temperature in many different fluids, and then forwards them to the process control systems. Complete access to all measurement data is possible at any time–using conventional 4–20 mA or digital data transmission via Modbus TCP.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer