Andrew Robinson explores how advanced permanent magnets — particularly samarium-cobalt (SmCo) and neodymium-iron-boron (NdFeB) — are changing modern medicine. From implantable devices and robotic surgery to targeted drug delivery, these high-performance materials enable miniaturized, precise, and biocompatible technologies that improve patient care. The piece also highlights the complex material science, coatings, and manufacturing processes essential to ensuring magnet reliability, safety, and performance in demanding medical applications

For millennia, humanity has been captivated by the enigmatic force of magnetism, perceiving its potential to unlock new frontiers in health and well-being. From the earliest observations of lodestones by Hippocrates in the 5th century BCE to the pseudoscientific theories of ‘animal magnetism’ proposed by Mesmer in the 18th century, this invisible power has ignited human imagination and scientific inquiry.

Today, the fascination continues, but with a profound shift from mystical wonder to tangible, groundbreaking applications that are dramatically advancing human health.

The advent of high-strength permanent magnets, particularly samarium-cobalt (SmCo) and neodymium-iron-boron (NdFeB), is now transforming magnetism’s ancient promise into a modern reality. These advanced magnetic materials are becoming ever smaller and more powerful, enabling revolutionary innovations in medicine.

These compact, high-performance magnets are transforming medicine. They enable advanced implantable devices, precision robotic surgery, and magnetic nanoparticles for drug delivery. They are making once-unimaginable therapies a reality.

The complexities of medical magnetic innovation

However, translating this potential into medical innovation is not simple.

It requires navigating complex material science. There are infinite variations in the formulation of SmCo and NdFeB, as well as advanced manufacturing processes, that optimise size, strength, and other critical attributes for medical applications.

The challenges are compounded by the need for biocompatible coatings to protect the magnets, and the complexities of the entire magnetic assembly. Additionally, selecting suppliers with expertise in medical applications, the ability to support regulatory and traceability requirements, and a commitment to resilient long-term supply is also crucial.

Medical applications using permanent magnets

Permanent magnets play a pivotal role in a diverse array of medical applications, functioning as indispensable components in diagnostic, therapeutic, and surgical technologies. For instance …

Implantable Devices: Permanent magnets play a critical role in the development of various implantable medical devices, including pacemakers, cochlear implants, and drug delivery systems. These magnets must be exceptionally compact while delivering high strength to ensure functionality in constrained spaces within the human body.

Additionally, biocompatibility is a paramount requirement; materials and coatings must be non-toxic and resistant to corrosion when exposed to bodily fluids. Stringent regulatory requirements governing the medical field add to the challenges, necessitating detailed testing and robust traceability to ensure patient safety and compliance with health standards.

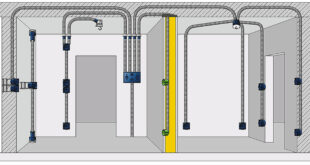

Robotic Surgery: Robotic surgery uses advanced permanent magnets in its precision control systems, including magnetic sensors and actuation mechanisms. The reliability and precision of these magnets are essential to support the accuracy and consistency demanded in delicate surgical procedures.

Robotic surgery offers numerous benefits, such as enhanced precision, minimally invasive techniques, reduced recovery times, and improved patient outcomes. These systems allow surgeons to perform complex operations with greater control and visualisation than traditional methods.

The magnets must exhibit exceptional thermal stability to perform effectively during extended surgeries in varying environmental conditions. Beyond these technical specifications, manufacturers face the challenge of ensuring magnets are free from magnetic field interference, which could disrupt other sensitive equipment in the operating room.

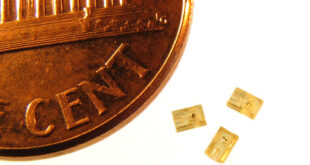

Magnetic Nanoparticles: Magnetic nanoparticles represent a cutting-edge and rapidly evolving application of permanent magnets in medical treatments, particularly in targeted drug delivery and hyperthermia therapy for cancer. These nanoparticles are designed to respond precisely to external magnetic fields, enabling doctors to direct them to specific parts of the body.

Developing permanent magnets for this application requires an extraordinary focus on miniaturization and the ability to generate highly localised magnetic fields. Furthermore, the materials used must be non-toxic and offer precise control mechanisms to avoid unintended side effects. The manufacturing process also involves high levels of precision and quality assurance, as even minor deviations can significantly impact medical outcomes.

Requirements for permanent magnets in medical applications

Permanent magnets used in medical devices must meet stringent criteria to ensure their effectiveness, safety, and compatibility with the human body. One of the most critical attributes is miniaturisation. The continual push toward smaller medical devices means that the magnets must be compact, yet highly functional, to integrate seamlessly into intricate systems such as implantable devices and minimally invasive tools.

This is particularly important for devices like catheters, which navigate narrow passageways in veins and arteries, where space is extremely limited. Smaller magnets not only allow for less invasive procedures but also improve patient comfort, especially for devices that remain in the body indefinitely.

Magnetic strength is also crucial. Despite their small size, these magnets must be powerful, generating strong, localised magnetic fields. This strength is vital for functions like sensing and actuation, enabling smaller magnets to perform as effectively as larger ones. This increased power density leads to further miniaturisation, enhancing the precision and capability of medical devices and magnetic nanoparticles.

Biocompatibility is indispensable to prevent adverse reactions within the human body. Materials used in these magnets must be non-toxic and capable of coexisting with tissues and fluids without triggering immune responses. This is especially critical for permanent implants, as any degradation or corrosion in the magnet could lead to device failures or, worse, health complications over time. To address this, state-of-the-art coatings and specialized materials are developed to enhance corrosion resistance and longevity.

Lastly, durability and longevity play vital roles, particularly for devices that must function reliably throughout the patient’s lifetime. Permanent magnets used in such applications are designed to endure years of operation without a loss in functionality or integrity, resisting corrosion and avoiding demagnetisation to maintain their safety and performance over time.

Resistance to high temperatures is particularly critical, especially in applications requiring sterilisation via autoclaving, or those where heat is generated from motor operation in medical robotics. Permanent magnets can lose magnetism at high temperatures through thermal demagnetisation, a process where heat disrupts the alignment of magnetic domains within the material.

This phenomenon occurs when the temperature exceeds the magnet’s specific Curie temperature, the point where thermal energy overcomes the forces holding magnetic domains in alignment. This loss of magnetic properties is often irreversible, resulting in a weaker or completely lost magnetic field.

The materials: SmCo versus NdFeB

When selecting permanent magnets for medical applications, samarium cobalt (SmCo) and neodymium-iron-boron (NdFeB) magnets are two of the most commonly used materials due to their high performance and unique properties.

Developed in the 1960s, SmCo magnets exhibit exceptional magnetic strength and inherent corrosion resistance, maintaining reliable performance with less demagnetisation and lower loss of coercivity at elevated temperatures. These characteristics render them highly suitable for MRI equipment, implants, and devices exposed to challenging internal biological environments, ensuring prolonged functional integrity.

Arnold Magnetic Technologies’ RECOMA 35E, the most power dense samarium cobalt magnet on the market, is specifically created for these highly demanding applications, including use at high temperatures (above 150°C) and highly corrosive environments. Arnold can adjust the composition of the SmCo material for performance at even more extreme temperatures up to 550°C.

NdFeB magnets, developed in the 1980s, surpass SmCo in magnetic strength. This makes them ideal for miniaturized medical devices like hearing aids and surgical tools., NdFeB magnets, however, require protective coatings due to corrosion susceptibility and are less thermally stable, limiting their use in high-temperature applications.Choosing between SmCo and NdFeB magnets depends entirely on the medical application’s specific needs. For compact devices needing high magnetic strength at controlled temperatures, NdFeB magnets are often better. However, for applications demanding high energy density and consistent flux at elevated temperatures, and exceptional resilience and longevity, SmCo magnets are typically the superior option.

Impact of manufacturing processes on magnet performance

Advancements in manufacturing processes have significantly improved the performance and reliability of permanent magnets for medical applications. One notable breakthrough is grain boundary diffusion, a technique primarily employed to enhance the properties of NdFeB magnets.

By utilizing grain boundary diffusion (GBD), we are able to reduce the amount of terbium or dysprosium required, both of which are currently on the export control list in China. This improvement makes NdFeB magnets more resistant to demagnetisation at elevated temperatures, expanding their use in more demanding environments.

Other critical processes include optimized sintering and hot deformation techniques, which enhance uniformity and performance. For example, Arnold Magnetic Technologies’ RECOMA SmCo magnets undergo a specialised process where powdered magnetic alloy is pressed into a ‘green block’ under a low magnetic field. This aligns the material’s magnetic domains. The block is then sintered in a controlled atmosphere, fusing the particles.

Additionally, injection molding enables the production of intricate, precise, and customised permanent magnets for medical applications by combining magnetic powder with polymer binders. This process facilitates complex geometries, multipole magnetisation, and finely tuned magnetic outputs, which are essential for applications demanding high precision, design flexibility, and seamless integration into devices such as surgical robotics, diagnostic tools, and implantable medical devices.

Coatings and magnetic assemblies

Beyond the selection of permanent magnet materials and optimised manufacturing processes, coatings play a critical role in ensuring the safety and longevity and safety of magnetic components, particularly in sensitive applications such as implanted medical devices.

The significance of coatings in medical applications is often underestimated or addressed too late in the planning and development stages. Factors such as biocompatibility and resistance to abrasion must be meticulously evaluated to meet the crucial requirements of these sensitive environments.

A bare magnet is usually unsuitable for implantation; for instance, neodymium iron boron magnets contain a high iron content that will corrode upon exposure to oxygen, leading to material degradation and potential adverse health effects. Consequently, the FDA rigorously scrutinizes the biocompatibility of coatings in implantable devices.

Nickel Plating: A common coating for NdFeB magnets in medical applications consists of a triple layer of nickel, copper, and nickel. While nickel is widely used in surgical tools, its suitability for long-term implantation is limited due to the potential for allergic reactions in sensitive individuals. Additionally, even a microscopic pinhole in the nickel coating can allow oxygen ingress, allowing corrosion.

To address these challenges, advanced coating technologies offer superior protection and biocompatibility:

Parylene Coating: Parylene is a biocompatible, corrosion-resistant coating applied via vacuum deposition, ensuring complete, pinhole-free coverage even in complex geometries. It offers excellent moisture resistance and high-temperature stability, making it ideal for small and micro-magnets used in medical devices.

Epoxy Coating: Epoxy coatings are widely utilized for corrosion protection in both industrial settings and bonded magnets.

The performance of any coating is inherently tied to the quality of the underlying magnet material. High-quality, corrosion-resistant base materials are essential to maximize the effectiveness of the coating. Collaborating with a magnet supplier experienced in medical applications is critical to selecting the most appropriate coating for each specific application.

Assemblies: The design and construction of assemblies that hold the magnet are also critical for safety and longevity. They must be carefully designed to prevent voids that could allow moisture or contaminants to compromise the magnet’s performance and safety. The assemblies must securely hold the magnet to endure operational stresses while maintaining proper alignment. Additionally, the materials must be biocompatible to protect both the patient and the magnet’s integrity. In medical applications, epoxy resin systems are also incorporated into advanced technologies like Arnold’s Wraptite composite encapsulation, which enhances both containment and corrosion resistance.

The role of magnetism in advancing medical technology

Magnetism has evolved from a scientific curiosity into a crucial enabler of modern medical innovations. Magnets now play an essential role in enabling some of the most sophisticated and impactful medical technologies available today, paving the way for continued advancement of medical treatment.

Andrew Robinson is with Arnold Magnetic Technologies.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer