In mining, the scale of machinery is immense, and so are the risks. Conveyors stretch for miles across rugged landscapes, bucket wheel excavators move thousands of tonnes per hour, and hoists pull ore from deep underground. Each of these systems relies on braking and clutch technologies to protect operators, safeguard equipment, and ensure continuous production. The difference between downtime and reliability often comes down to how intelligently these systems are designed and controlled.

Hydraulic brakes have long been the standard for large-scale mining equipment because they deliver the force and reliability required for high-inertia machines. But modern mines demand more than brute stopping power. They need systems that can react smoothly, adapt to changing load conditions, and safeguard components during emergencies such as power failures. Intelligent hydraulic braking is no longer an optional upgrade, it has become a crucial element of safety, efficiency, and uptime in the mining industry.

Controlled braking

One of the key advances in this field is the development of programmable soft braking control. Unlike conventional braking methods that can place enormous stresses on belts, shafts, and bearings, soft braking allows torque to be applied gradually and released just as smoothly. This not only reduces mechanical wear but also prevents dangerous oscillations or uncontrolled over-runs. The advantage is clear: better protection for equipment and a safer working environment for personnel.

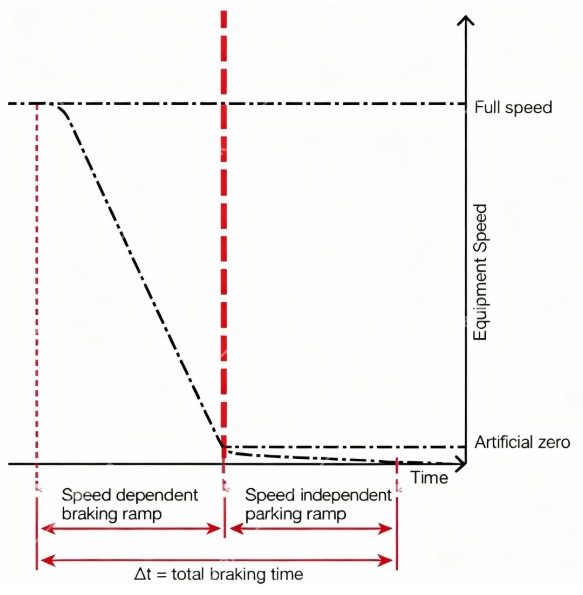

Svendborg Brakes, a Regal Rexnord brand, has pioneered this technology with its SOBO iQ intelligent braking controller. The SOBO iQ system continuously monitors variables such as line pull or conveyor speed, adjusting brake torque in real time to maintain control under all conditions. When the SOBO iQ receives a brake command, it energizes/de-energises the valves in order to modulate the pressure to follow the predefined braking ramps. A unique pressure feedback feature ensures quick and precise control over torque output of the braking system and, in turn, helps to ensure a predictable stopping sequence.

At a major copper mine in Chile, this technology was applied to a take-up winch on a 2.65-kilometre conveyor transporting over 11,000 metric tonnes of ore per hour. By enabling controlled release of belt tension, even during power failure, the SOBO iQ prevented damage to both the belt and mechanical components, an achievement that marked the industry’s first ‘smart’ take-up winch.

New generation of brake pads

Beyond control, braking systems in mining must also address health and safety challenges that extend beyond machinery. Dust, for example, is a persistent hazard in mining environments, contributing to respiratory risks and harmful working atmospheres. Brake pads can be a surprisingly significant source of airborne dust.

Recognising this, Svendborg Brakes has developed a proprietary range of environmentally friendly brake pad materials that drastically reduce dust emissions without compromising performance. Designed, manufactured, and tested in-house, these pads can be tailored to the specific requirements of each application, combining operational reliability with improved workplace conditions.

Brake pads need to be optimised for shape, size surface area and contact points to ensure optimum braking force, heat dissipation and wear uniformity. In addition, regulations on the registration, evaluation, authorization and restriction of chemicals (REACH) must also be followed to restrict the use of harmful substances.

With so many elements and compounds used in traditional brake pad formulations, Svendborg Brakes has eliminated the use of asbestos, nickel and antimony and kept levels of mercury, chromium 6+, lead and cadmium below 0.1% and still optimized braking effectiveness. At a point when environmental concerns are high on the agenda for many businesses, these green alternatives provide an excellent solution.

Integrating connectivity

The move toward smart braking is not only about machine control and safety but also about data. Mining is entering the era of predictive maintenance, where equipment health is monitored in real time and potential failures are identified before they cause downtime. By integrating industrial internet of things (IIoT) solutions with braking systems, Regal Rexnord brands have created platforms where performance data can be accessed from anywhere, enabling mine operators to plan maintenance precisely when it is needed.

This approach has already delivered significant results at one of Europe’s largest lignite mines, where a fleet of bucket wheel excavators was upgraded with Svendborg’s IIoT-enabled systems. Operators reported smoother performance, extended component lifespans, and a halving of regular inspection intervals, all translating into major cost savings and higher uptime.

Durability and reliability

Complementary technologies across Regal Rexnord’s portfolio reinforce these advantages. Steiber’s RDBK high-speed backstop protects conveyors from dangerous reverse rotation, while Industrial Clutch’s LKB multi-plate brakes bring compact, high-energy stopping capability to crushers and mills. For large rotating equipment, both Svendborg Brakes and Twiflex offer hydraulic caliper brakes that combine fail-safe spring application with hydraulic release, delivering dependable emergency and parking functions even in the harshest conditions.

Durability is another defining requirement for mining machinery, which often operates in corrosive environments where dust, humidity, and salt take their toll. To combat this, Regal Rexnord braking systems are protected with advanced coatings such as C5 medium-grade paint systems applied to non-functional surfaces. This attention to detail in materials engineering can extend service life and reduce the maintenance burden, reinforcing the overall reliability of the equipment.

These innovations are helping mining companies transition toward a future where safety, sustainability, and efficiency are essential. Hydraulic brakes and clutches are no longer just about stopping machines; they are about enabling smarter, safer operations that can withstand the pressures of modern mining.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer