When an engineering team requires an industrial enclosure, dedicated expertise will optimise the design. Expert guidance in specification from the outset, through to customisation and bespoke development, will achieve the most effective enclosures to support the wider application long term. What’s more, involving the support of an enclosure designer can also make the project faster and more cost-effective as well. Chris Lloyd explains

When an engineering team develops a machine or a larger system, their planning and research will identify the detailed requirements that the design must fulfill. The result of these findings could lead to the development of a particular control mode, or the performance enhancement of an existing feature, or perhaps the capability to use the machine system in a specific environment. Whatever the requirement, these features and functionalities are developed specifically to resolve operator needs and provide value to the end user.

Numerous components are combined to deliver these features, including enclosures that house and protect electronic components and electrical junctions. So, by extension, it is logical to integrate an enclosure that’s also designed specific to requirements, and that will contribute to optimising the overall features of the machine or system.

Engineering expertise or online selection?

Whether the enclosure is protecting controls, sensors, safety devices, or electrical terminals, it might be possible for an engineering team to directly specify and procure an off-the-shelf housing from an online retailer or reseller. However, often elements of customisation are required, and these adaptions must maintain the integrity of the enclosure without adding significant time and cost.

An alternative approach for an engineering team is to work from the outset with an enclosure designer who is conversant with wider equipment or system development needs. This enables the engineering team to draw on specific expertise and experience as required to achieve the optimum enclosure design and integration. Moreover, this approach will not only make delivery of the project significantly faster, but considering total costs, it can also be more economical as well.

When partnering with an enclosure designer, the process begins with a detailed evaluation of the application’s unique demands. This means analysing the requirements of the enclosure, such as the IP or IK level, plus wider environmental considerations such as temperature extremes or condensation protection. The specification also involves the form factor, including cabling and component layout inside the housing.

Customisation requirements

Providing the required design criteria can be achieved, including testing and certification for safety, conformance, and durability, an off-the-shelf enclosure could be integrated, providing advantages in time and cost saving. To achieve this, it is highly beneficial to work with an enclosure manufacturer that offers a wide range of designs, materials, and sizes, making a match much more likely. If enclosures are designed with flexible features, like hole knock outs with protective seals, this creates further options.

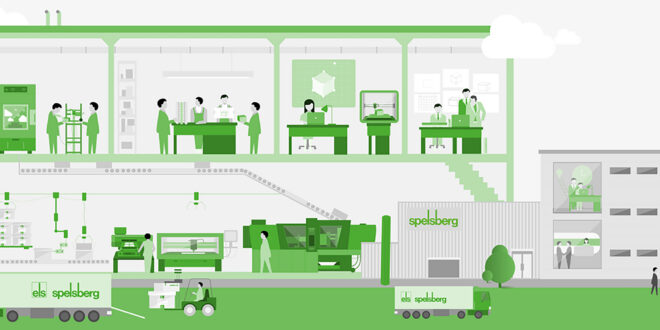

If customisation is required, working with an already flexible range makes the modification process much more efficient. The first stage in customisation is design; an enclosure manufacturer could work to a supplied CAD drawing, or they could create the design according to stated requirements. At Spelsberg UK, the engineering team is CNC-equipped and can provide a range of customisation options, such as adding cable entry points in specific locations, through to tapping threaded holes, or cutting inserts for HMI screens. Bespoke work could also involve colour printing onto the enclosure, such as OEM branding or user instructions.

The primary advantage of working with an enclosure manufacturer that offers in-house customisation is accountability. This ensures that the engineering team is provided with the design updates they need, without impacting the enclosure’s protection integrity. In-house customisation also saves time, and Spelsberg UK can provide a customised prototype within a week.

Bespoke engineering and assembly

If customising an existing enclosure design still doesn’t fit precise requirements, a bespoke housing might be required. The typical barrier to selecting a fully tailored enclosure is time and cost, however, if the manufacturer’s production process has been developed to accommodate bespoke designs, a unique enclosure can be achieved in a much shorter timeframe. At Spelsberg’s manufacturing plant in Germany, the modular tool concept is the basis of production, enabling different manufacturing techniques for small or large order quantities. Combined with Spelsberg’s materials and design feature development, a fully tailored enclosure can be rapidly created.

Ahead of fulfilling an order of completed enclosures, an assembly service is a time-saving enhancement, which could include options such as installing terminal equipment, pre-wiring membrane keypads, or inserting cable glands. While this again maintains accountability with a single supplier, an assembly service reduces demand on OEM resources and speeds up internal assembly processes.

When an engineering team is developing a machine or system, an enclosure isn’t a consumable item. Requiring its own detailed specification, and often some level of custom development, an enclosure design requires engineering expertise in its own right. Partnering with an enclosure manufacturer that offers the complete array of expertise is the optimum approach to achieve this.

Chris Lloyd is Managing Director at Spelsberg UK.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer