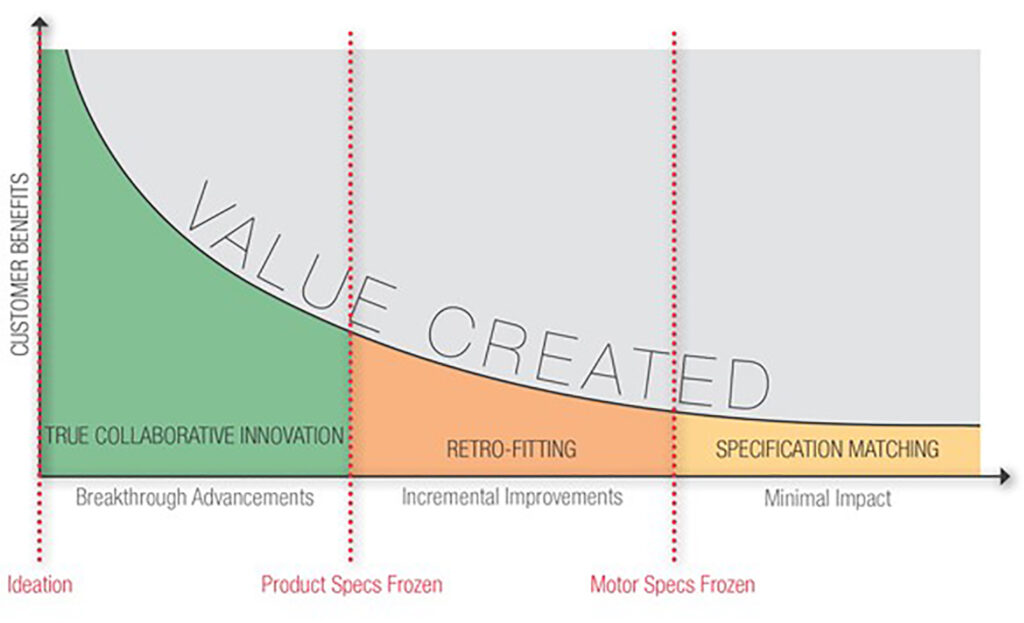

Early involvement of motion designers in an application or machine means that the most effective results can be reached early in the process with no impact in time to market.

For design applications that depend on motion, whether that is a robot, a surgical power tool, or a satellite control system, miniature DC motors are commonly used thanks to their performance and compact footprint. To accurately specify a miniature motion solution, understanding the role of inertia is crucial. While sizing tools can assist in this process, a thorough analysis of the application’s wider design, combined with targeted customisations, can help optimise performance.

When specifying a miniature motor, inertia is a key consideration. As a measure of a motor’s resistance to changes in rotational speed, its inertia value is based on a calculation involving the mass and radius of its rotor. High rotational inertia presents a greater challenge in accelerating the system, whereas a lower inertia indicates ease of acceleration. As less energy is required to accelerate or decelerate a motor with lower inertia, they are more energy-efficient, and this can make a significant difference in applications with frequent start-stop cycles. Motors with lower rotational inertia also usually offer improved control, which is a positive attribute for applications that require precise positioning.

While it may seem that lower inertia is optimal, matching the motor’s inertia with the load’s inertia is essential. In the most basic terms, if the load’s inertia is significantly greater than that of the motor, the motor will struggle to control the outmatched mass or size. The closer the inertia match, the more accurately the motor and drive system can control the load, especially in applications requiring precise movements.

Tackling inertia mismatch

The common challenge is an inertia mismatch caused by a high load-to-motor inertia ratio. This kind of imbalance can introduce stability issues that cause increased response times and lower system bandwidth. It can also result in wasted energy as the motor works harder to move the load. At its most serious level, it causes oscillations and resonance that could damage the motor as well as the load and connections.

Simplifying the transmission

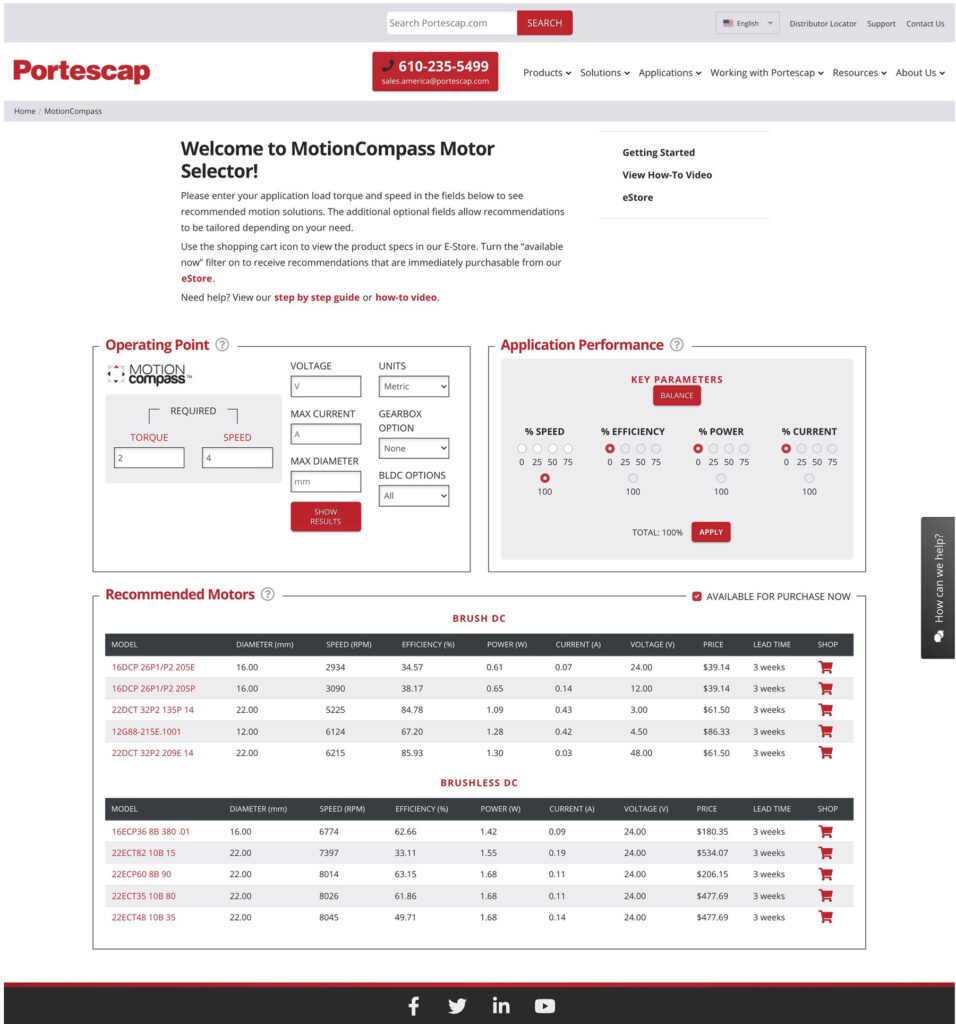

Many motor manufacturers provide online tools and calculators to assist design engineers when selecting a miniature motor, including those such as Portescap’s MotionCompass™. However, a comprehensive awareness of the contributing factors to inertia is useful in motion design and integration. While a motor catalogue and sizing tool can provide the inertia rating, holistic design tactics can improve overall application design and help close the inertial gap.

Although a 1:1 inertia ratio is theoretically perfect, it’s neither practical or necessary to achieve. In real-world applications, striving for an inertia ratio close to 1:1 can result in oversized components, higher system costs, and increased energy consumption. Instead, each use case has an acceptable range, although for applications that demand dynamic control and positioning, like high-speed assembly or textile yarn guides, a low load-to-motor inertia ratio is crucial.

Gear reduction is a common step, and this technique reduces the load inertia in proportion to the square of the gear ratio. Moreover, modern control systems with advanced algorithms and high-resolution feedback devices can address inertia mismatch issues. However, the adverse effects of inertia mismatch, or a high load to motor inertia, can become worse by a lack of stiffness in the system, also known as load compliance. To minimise these issues, we can look to wider components of the application or machine to optimise rigidity.

Load compliance challenges are more common in indirect drive systems. Here, the motor is not directly coupled with the load but is connected through one or more power transmission elements such as a gear mechanism, pulley belt systems, chain drives, or ballscrews. To simplify an indirect system to increase stiffness, as well as reduce further potential causes of inertia, it is useful to consider the effect of each connected component beyond the motor shaft.

Direct drive systems

For demanding applications that would significantly benefit from a close motor-to-load inertia ratio, starting with the possibility of a direct drive system is advisable. This motion design approach will keep the number of power transmission elements to a minimum while optimising compliance.

With a direct drive, the motor is directly coupled to its load. This connection removes the inertia resulting from power transmission components, and the less inertia the motor needs to overcome, the less torque it requires to meet the desired acceleration rate. A direct drive system also minimises effects such as backlash, the play between mechanical components that can also impact power transfer and system reliability.

To minimise the overall inertia within an application or machine, as well as optimize the inertia balance between the motor and the load, a comprehensive review of all design aspects impacting the motion cycle is advisable. To effectively achieve this, involving motion engineers early in the overall design process is preferable.

Firstly, engineering input can help to improve the wider machine or application design and advise on the best motion solution approach. Secondly, early involvement of motion designers means that if customisation is required for the motor or transmission, the most effective results can be reached early in the process with no impact in time to market.

Portescap provides a ready supply of tools and motor data to help guide original equipment manufacturer (OEM) engineers in their specifications. Most importantly, the company’s motion specialists are available to discuss design and customisation needs across a range of applications.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer