While solar, wind and other green power sources offer enormous reserves of emission-free power, they can also be intermittent. If these renewable sources generate more supply than demand at any one time, they can overwhelm the grid. In the UK where wind produces about 30% of all electricity, the grid operator will often pay developers to turn their wind turbines off. This costly process known as curtailment is a growing issue as the UK introduces more wind power supply into the grid.

Highview Power’s liquid air energy storage (LAES) system represents a significant opportunity in the global energy transition, delivering more renewable energy into the power grid through its innovative storage technology. The system captures excess power, releasing it back at times of high demand or reduced generation. It also offers critical grid stability services.

Alternative energy storage

Highview Power CEO Richard Butland explains how the system works: “Excess energy is used to clean and dry air, which is then refrigerated and compressed until it liquefies and can be stored in tanks. When power is needed, the liquid is pumped at high pressure and heated, so it expands, and drives a gas turbine to generate electricity.”

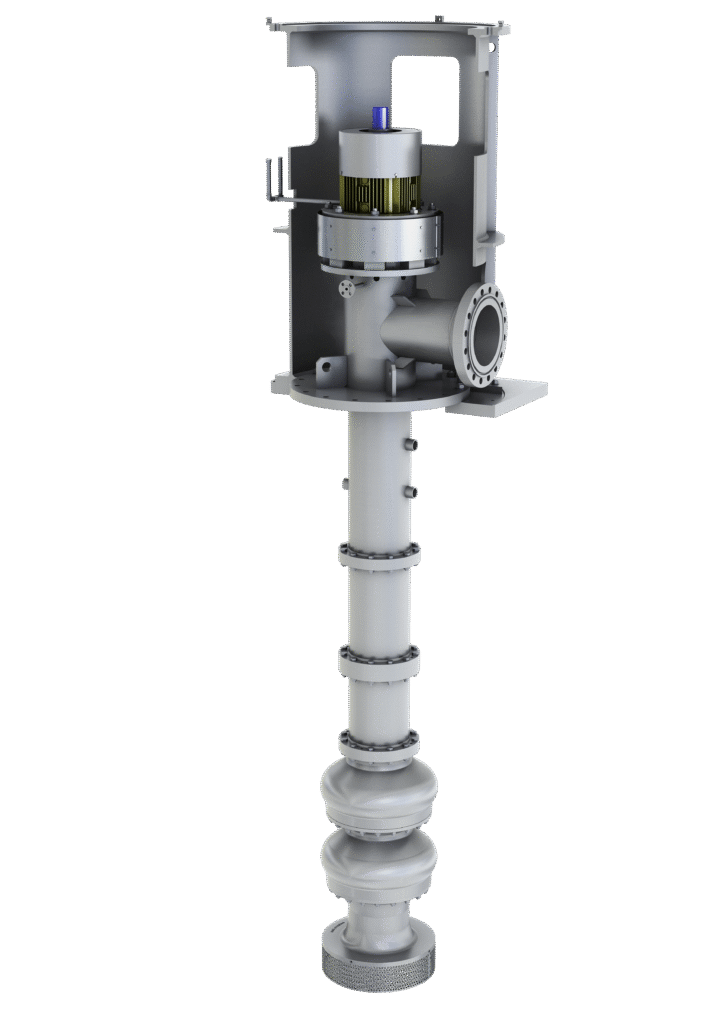

Sulzer will supply Highview Power with cryogenic pumps and a molten salt storage system. The new Carrington, Manchester, facility will use these molten salt processes to recover and store otherwise wasted energy for use in heat generation, further maximizing its efficiency.

As well as its market leading technology, Highview Power also recognised the convenience of Sulzer’s local distribution networks in the UK. Added to this was the depth of Sulzer’s experience in pump technology, its global reputation for engineering excellence and its delivery of high-quality, efficient solutions to the energy transition market.

A world-class collaboration

With over fifty years’ experience in molten salt pump manufacture, Sulzer’s expertise provides invaluable support for innovative projects like this. Their robust, proven designs ensure reliable service and minimum downtime in an industry where every second matters.

Sulzer pumps also lead the way in molten salt applications, and expected peak temperatures in the new plant of around 435°C sit well below the 650°C standard tolerance of Sulzer’s specialist pumps. Nonetheless, the LAES project poses specific engineering challenges around integrating both cryogenic pumps and molten salt pumps efficiently.

Explaining the benefit of the system, he continued: “Molten salts represent a state-of-the-art solution to renewable energy storage, where energy providers can tap into excess production to smooth output at peak times and avoid costly excess. Given the collaborative nature of the project, we anticipate a 14-month manufacturing and delivery timescale despite the complexity involved, and we expect to see the plant operational by March 2027.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer