Atlas Copco‘s on-site nitrogen generation system is a solution for high-pressure applications such as laser cutting and electronics manufacturing − an all-in-one solution that can handle the peak demands of applications as varied as fire prevention, pipeline services, and aviation tyre inflation. Now, with the introduction of advanced components and additional models, users get even better performance and the flexibility to customise the package to their exact needs.

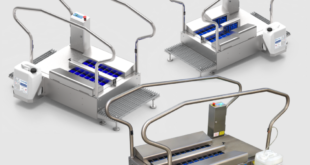

Atlas Copco’s nitrogen skid package is a complete high-pressure nitrogen generation system built onto a compact and pre-commissioned skid. Its plug-and-play installation makes on-site gas production easy and seamless. The Atlas Copco nitrogen skid package comes in a 40-bar and a 300-bar variant. Both now feature additional models, expanding the entire range to twelve models in total.

For customers that make the switch from purchasing gas to on-site generation, Atlas Copco’s latest nitrogen skid package offers continual unlimited supply and independence from vendors’ scheduled bulk deliveries, as well as the expense of ordering, transportation, and storage.

Atlas Copco’s continuous investment in compressed air and gas generation innovation has resulted in new, industry-leading products and components that are now included in this next generation of the Atlas Copco nitrogen skid package:

• GA oil-injected rotary screw compressor with VSD technology: The latest Variable Speed Drive compressors match their motor speed and power consumption to users’ nitrogen demand to deliver double-digit energy savings. This significantly reduces their operational costs and environmental footprint.

• NGP+ PSA nitrogen generator: Atlas Copco’s premium nitrogen generation system operates with Pressure Swing Adsorption technology to offer a guaranteed gas purity of up to 99.999%. The NGP+ optimises its air consumption based on the actual nitrogen use to ensure energy savings at full and at low load. As a result, the recently expanded and enhanced range delivers superior performance combined with low cost of ownership.

• Nitrogen booster: The high-efficiency booster comes in a 40-bar version for on-demand nitrogen generation and in a 300-bar option for cylinder storage.

• Nitrogen storage: A 40-bar receiver and 300-bar cylinder racks are also offered.

• All components, including dryers and filters, are built to Atlas Copco’s quality standards. They are tested to work together for optimal, plug-and-play performance and reliability.

“Versatility has always been an important benefit of the nitrogen skid package and this latest generation gives users even more flexibility,” said Ben John, Business Line Manager, Industrial Air “With more models available, users can choose a nitrogen skid package that fits their exact needs along with the freedom to select and size their compressor, nitrogen generator, booster, and air treatment for a truly customised, top-quality performance. High purity, high flow, high-pressure nitrogen from one skid package. Self-producing nitrogen has never been this easy.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer