Parker Hannifin has introduced a new family of ISO15552-certified pneumatic cylinders.

Available in bore sizes from 32 to 125mm, the P1F series is suitable for general industrial applications, such as linear motion, clamping, lifting and controlling tasks in a range of operating environments.

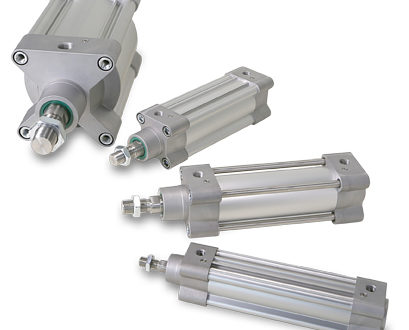

The smooth profile version P1F-S cylinder is complemented by a P1F-T tie-rod version, with an actuator for ‘clean’ applications – the P1F-C, due for release next year.

Fully compliant with ISO15552, which sets out standard interchangeability dimensions for pneumatic cylinders with detachable mountings, the P1F-S range of smooth profile cylinders is suitable for deployment in numerous working environments.

For example, standard and outdoor version feature, polyurethane sealing technology to provide extended operating life in markets such as materials handling, automation and transport.

For applications where extra chemical resistance is required – where the scraper in the front-end cover might be exposed to aggressive chemicals, P1F-S cylinders can be fitted with a scraper made from fluoroelastomer compound (FKM).

Derivatives are also available with metallic scrapers for use in harsh, extreme.

Finally, an ATEX-rated smooth profile version, designated P1F-A, is suited to potentially explosive environments.

The smooth profile design of P1F actuators promotes easy cleaning and offers good aesthetics.

Further customer benefits include stainless steel cushioning screws on one side, as well as air ports and sensors to allow quick access to all settings from the top on one face.

Wiper/rod seals are combined in a single design feature to reduce friction and increase the working life of the cylinders.

PTFE piston-rod guidance meanwhile, serves to reduce radial play. Industry 4.0 readiness is ensured through the provision of two T-slots on the top face that can accommodate sensors such as Parker’s P8S CPS Analog or IO-Link sensors.

A wide range of cylinder and piston rod mountings and sensors can be supplied to suit all customer applications.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer