Harendra Singh and Ravi Kuma examine a new approach to predicting reed critical frequency (RCF) in vertical motors and how this method more accurately represents vertical motor dynamics, enabling designers to anticipate resonance behavior early and optimize system reliability before equipment is built

Vibration in rotating machinery is a leading cause of premature failure, costly downtime, and safety hazards. For operators of vertical motors, one of the most important vibration-related concepts to understand is reed critical frequency (RCF). This natural frequency of a motor system plays a central role in determining whether a motor will operate smoothly or succumb to damaging resonance conditions.

By better understanding RCF, why vertical motors are especially prone to resonance risks, and how engineers can accurately predict and avoid these conditions, equipment manufacturers and end users alike can significantly extend machine life and reduce maintenance costs.

What is reed critical frequency?

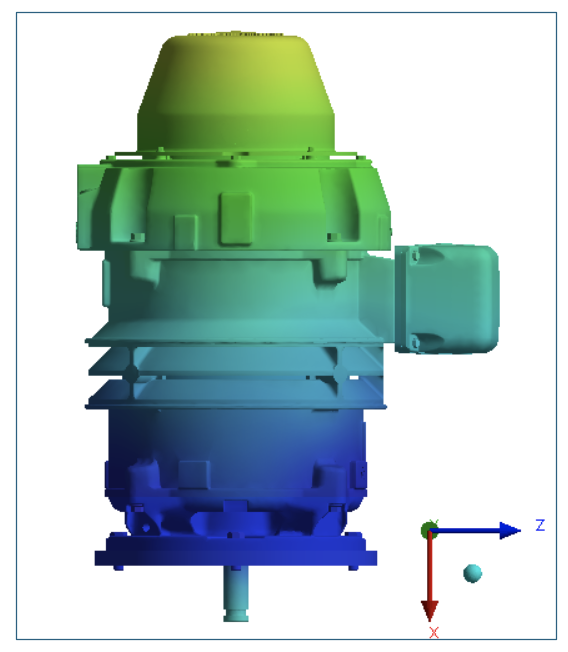

Reed critical frequency is the first natural bending frequency of a vertical motor system. To visualize this, consider how a tuning fork vibrates when struck; the fork oscillates at a specific frequency, amplifying the input energy. Vertical motors behave in a similar way. Because their shaft and rotor assembly are upright, they act like a cantilevered reed: flexible, unsupported at one end, and prone to bending motion under excitation.

RCF depends on factors including shaft length and stiffness, rotor mass and distribution, and bearing support stiffness. When the natural frequency coincides with an excitation frequency, such as the 50 or 60 Hz power supply, the motor enters resonance. Even small inputs of energy can create disproportionately large vibrations. Resonance accelerates wear on bearings, thrust assemblies, and foundations, and in the worst cases, it can cause catastrophic component failure.

Why vertical motors are especially vulnerable

Unlike horizontal motors, vertical motors rest on a single base. The design makes them more flexible, especially with added overhung loads from couplings, impellers, and pumps. This reed-like structure makes them uniquely susceptible to resonance.

Operators can sometimes detect when a motor is approaching resonance. Vibration monitoring shows sudden spikes in radial vibration, with amplitudes peaking near the critical frequency. Motors may produce a low-frequency hum, buzzing, or rattling. High displacement at the top cover, cycling vibrations near RCF, and visible shaft wobble are further signs. Premature bearing deterioration is also common, often accompanied by overheating, thrust bearing wear, and coupling misalignment. Over time, the foundation itself may loosen, compounding the problem and creating long-term risks.

In the short term, resonance can trigger alarms or nuisance shutdowns. In the long term, it can bend shafts, degrade thrust bearings, and force costly motor replacement. Because vertical motors are often paired with pumps, the consequences ripple through the system, causing downtime and expensive maintenance. In some cases, unchecked resonance can even result in catastrophic failure.

Traditional methods of determining RCF

The pump industry requires accurate RCF values early in the design process, as pump manufacturers must model the combined dynamics of the pump, motor, and foundation. Traditionally, engineers have turned to finite element analysis (FEA), bump tests, and simplified formulas.

FEA builds a structural model of the motor to simulate natural frequencies. Results are reliable, but the process is time-intensive and resource-heavy, making it impractical for variations in enclosure designs, frame sizes, and materials. The bump test involves exciting a finished motor to measure its natural frequency response. This produces accurate data but requires a fully assembled motor, delaying results until it is too late in design. Simplified methods like NEMA MG 1 offer quick estimates but oversimplify system dynamics, assume rigid foundations, and ignore load effects. Errors can exceed ±20%, creating uncertainty for pump manufacturers.

These drawbacks, whether cost, speed, or accuracy, leave manufacturers dissatisfied. Inaccurate predictions prevent pump manufacturers from designing bases that properly account for dynamic forces. Errors are compounded when plants retrofit VFDs or modify equipment without reevaluating RCF. The industry now demands more reliable predictive data.

A more accurate alternative

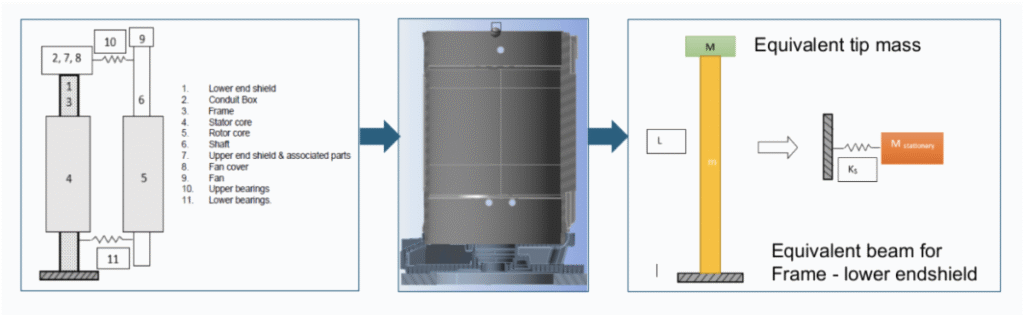

Recognizing these limitations, Wolong Electric America engineers developed a mathematical model that takes a different approach. Instead of relying on a single-degree-of-freedom assumption, Wolong Electric America’s method is based on a two-degree-of-freedom system. This accounts for contributions of both stationary and rotating parts, as well as bearing stiffness. By incorporating each component, the model reflects the true dynamics of vertical motors more completely.

The model represents the motor structure by treating the frame and lower endshield as a flexible beam that supports the stationary components, while the rotating parts are connected through the bearings. This captures how both the fixed and moving elements of the motor influence resonance. Equivalent mass is calculated for each part using enclosure-specific power factors derived from the Timoshenko beam model. This allows the tool to account for variations in enclosure type, frame or P-base size, and the location or orientation of attached parts, ensuring accurate predictions across configurations.

The result is a predictive tool with accuracy improved to ±10%, and in some cases as close as ±5%. Just as importantly, the process is significantly faster, reducing calculation time by 40–50% compared to traditional methods. Engineers can input design parameters into a spreadsheet-like tool and receive outputs not only for RCF, but also static deflection and center of gravity. These are exactly the values pump manufacturers need to design pump bases and avoid resonance.

Functioning as a digital twin or ‘virtual motor’, the model allows engineers to quickly simulate changes to configuration, mass, support structure, or mounting and assess the impact on resonance behavior. Engineers can then test design adjustments, such as altering frame material, rotor or bearing stiffness, or leveraging Wolong Electric America’s built-in provisions for adding mass to shift RCF, ensuring resonance risks are addressed before equipment is built or installed. This flexibility enables both motor and pump designers to fine-tune systems without costly delays.

An industry shift toward predictive accuracy

For many years, manufacturers relied on generalized values across product lines, often resulting in errors of 40–50% between predicted and actual resonance points. In the past, with fixed-speed motors, this was tolerated. Operators could avoid resonance zones by staying within stable ranges.

With the introduction of variable frequency drives (VFDs), motors now operate across broad speed ranges, often passing directly through resonance frequencies. This shift has heightened the demand for accurate predictive tools. Rather than relying on reactive maintenance after failures, the industry now embraces proactive analysis during the design stage.

Advances in computing power and modeling have made this shift possible. Digital models act as accurate surrogates for physical motors. By simulating the complete system, including rotating and stationary components, bearing stiffness, and support structures, engineers can anticipate resonance issues early.

It is within this context that Wolong Electric America’s innovation has proven valuable. After years of research and validation testing, the company’s two-degree-of-freedom mathematical model offers a balance of speed, accuracy, and adaptability. By enabling faster calculations and incorporating real-world design variations, Wolong Electric America provides motor and pump manufacturers with the tools they need to make smarter decisions.

Because the model can reflect even minor changes, such as adjustments to materials, frame size, or added mass, it empowers engineers to refine designs with confidence. The result is a more predictable and resilient motor-pump system, one less prone to downtime, costly failures, or unexpected maintenance. Wolong Electric America stands out as an ideal partner for companies seeking to mitigate resonance risks and optimize long-term performance.

Beyond the resonance point

Traditional approaches forced manufacturers to choose between precision, speed, and cost. Wolong Electric America’s model demonstrates that these trade offs are no longer necessary. With a method that is fast, accurate, and easy to apply across product lines, engineers can anticipate and mitigate resonance risks during the design stage rather than responding to failures in the field.

As VFD-driven systems become the norm and the industry pushes for greater efficiency, predictive accuracy around resonance will only grow in importance.

Harendra Singh is Lead Engineer, and Ravi Kumar is Category Manager, at Wolong Electric America.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer