Netzsch Pumps USA’s the NEMO and PERIPRO pumps have the ability to transfer complex fluids and provide accurate and repeatable metered flows of viscous, shear sensitive, and high solids-laden materials which makes them well suited for lithium battery production.

Netzsch NEMO Progressing Cavity pumps are the best pumping technology solution for the battery manufacturing process and the standard in the industry because of their advanced capabilities. They can convey this industry’s wide range of abrasive slurries and harsh fluids without pulsation and meter them with extremely high precision. No metal-to-metal contact of the pump’s wetted parts and lubrication-free shaft joint options ensure no contamination of the products. These powerful pumps can also operate at slow speeds supplying very steady, low flows. NEMO pumps can be provided with many different materials of construction including abrasion-resistant hardened steel, ceramic rotors, and one of over 30 stator elastomers. Netzsch formulates the elastomer compounds in-house to best withstand all of the harsh chemicals and solvents in the liquids.

NEMO Progressing Cavity Pumps particularly excel in the very demanding electrode coating and slurry mixing applications. For coating applications, these pumps continuously feed even highly viscous slurries with high concentrations of solids in a pulsation-free manner to the coating system achieving the critical thin and uniform coating thickness. The mixing pumps accurately meter the raw materials for a perfect mix to ensure consistent and optimum battery performance. NEMO pumps also precisely meter or transfer ceramic slurries, electrolytes, adhesives, resins, and many other battery process fluids including those with aggressive solvents.

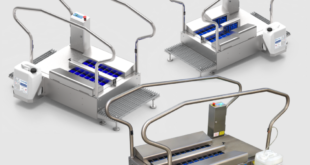

PERIPRO Peristaltic Pumps have a heavy-duty construction for demanding applications, with large, easy-to-maintain rollers for longer service life. These pumps are ideal for complex fluids, such as abrasive, corrosive, viscous, and delicate products.

Ultimately, this pump design provides energy savings up to 30%, and requires 90% less lubricant when compared to other peristaltic pumps using shoe technology.

Among the particular features of PERIPRO Peristaltic Pumps that make them suitable for lithium battery manufacturing includes the fact that it is a compact, seal-less design, so no hazardous emissions can escape. The hose material has excellent chemical resistance and is provided in several elastomeric choices.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer