Drinks producer ICB Distillers wanted to reduce production costs while maintaining hygiene and product quality. Introducing Bürkert’s FLOWave flowmeter to provide accurate measurement without media contact, ICB Distillers has been able to minimise product wastage as well as decrease the volume of water required to flush its CIP process.

At ICB Distillers’ UK Middlesbrough site, the company produces spirit-based drinks, developing beverages for its own range as well as blending and mixing drinks for various brands and supermarkets. The plant also hosts a bottling facility, producing around 30 million retail-ready bottles each year. Spirits such as rum as well as ethanol are transported to the facility where they are mixed with an array of ingredients, such as fruit juices and creams, plus purified water and sugar, according to the recipe.

Managing product quality

When the tanker arrives at ICB Distillers Middlesbrough, the spirit or ethanol flows into a bund containing six tanks. Then, when drinks production takes place, the alcoholic liquid is fed into mixing tanks according to the recipe requirements and alcohol by volume (ABV) level of the particular beverage. This pipe matrix is flexible and allows ICB Distillers to achieve various mixes and create new products as required.

Accurate flow measurement of the spirits and ethanol is crucial to ensure the quality of the beverages, as well as precisely manage stock and optimise the cost efficiency of production. It’s also vital that flow measurement devices integrated into the matrix maintain hygiene, and with various spirits flowing through the pipes at any one time, preventing cross-contamination is also essential.

ICB Distillers also relies on a clean-in-place (CIP) process, and while it must rinse away all chemicals, minimising water consumption is key to lowering costs and managing sustainability. Up to now, residual spirits within the pipe matrix have also been washed away in the CIP process, with product wastage adding significant cost.

Reducing production costs

“Spirits left in the line have been washed away during CIP,” explains Gary Bragman, Project Manager at ICB Distillers. “It was important for us to move to a system that could integrate a pigging system, save on water, and control product flow with greater accuracy.”

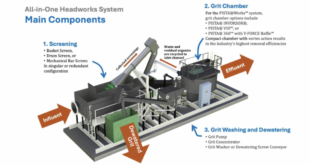

A pigging system is named after the ‘pig’, a bung that is pushed through the pipes to recover product and assist in cleaning the lines ahead of CIP. To achieve this, a pipeline integrating flow meters that wouldn’t obstruct the ‘pig’ was required.

Engaging with Bürkert, engineers Kieran Bennett and Chris Hughes from the flow specialist specified the FLOWave flowmeter. Free of seals, electrodes, and components within the flow path, the device minimises the potential of bacteria accumulation and is easy to clean. To achieve accurate flow measurement, FLOWave sends high-frequency Surface Acoustic Waves (SAW) across the fluid where changes in flow, mass, temperature, and density, affect the waves’ speed and attenuation. The resulting detection of the signal achieves precise measurements without direct contact with the media.

Reduced water use in CIP

Bürkert’s FLOWave was also specified to improve the cost effectiveness and time required for CIP. A typical cleaning process operates by setting cycle times of chemical washes followed by clean water flushes. To ensure completeness of the flush, conservative estimates are applied, but this results in a high volume of water use. However, FLOWave can detect the phase change in the media, referred to as the differentiation factor. This accurately informs when all chemical traces from the CIP process have been flushed away, enabling a shorter flushing period and reduced water use.

With at least one CIP process per day, and tens of thousands of litres of water involved per year, the cost and time saving is significant,” says Kieran Bennett, Bürkert. “Total water saving can be up to 50%, which also achieves a significant environmental benefit.”

With Bürkert’s FLOWave flowmeters installed on each of the feedlines from the bund, ICB Distillers’ phased commissioning set the first meter live in May, and its flow control accuracy is already improving production efficiency.

Improving production efficiency

“Previously, challenges in accuracy controlling the flow of spirits using mag-based flow meters meant continually adjusting the mixture, adding highly purified water to help meet the ABV level, as well as sugar and other ingredients,” explains Gary. “Now, with Bürkert’s FLOWave, we can get a much more accurate measurement of what’s going into a mixing tank before pumping it to the line. From initial batches of 500 litres, each one has been accurate to less than two litres difference.”

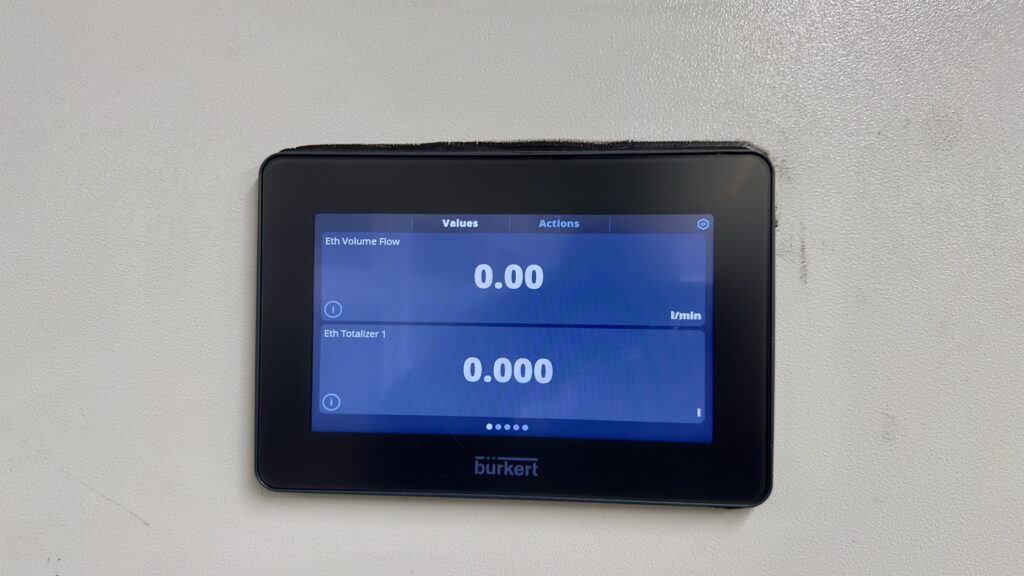

The flow meters are installed within an ATEX Zone 2 hazardous area, while the devices communicate back to a Bürkert ME61 display located in a separate control room. The FLOWave device integrates analogue and digital outputs, and by wiring the digital communication ports together in a daisy chain formation, a single cable, approximately 25 metres long, connects to the display via Bürkert’s EDIP CAN-based protocol. Providing individual batch and total flow rates, the data enables ICB Distillers’ operations team to accurately keep track of produce.

With the additional flow meters set to be commissioned in the following months, ICB Distillers will be in a position to extend the pigging system across the matrix. Minimising spirit wastage and reducing the volume of water used in the CIP process is set to achieve a rapid return on investment for the beverage producer. Meanwhile, less time required for the updated cleaning process has the potential to improve productivity while maintaining the same high level of hygiene.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer