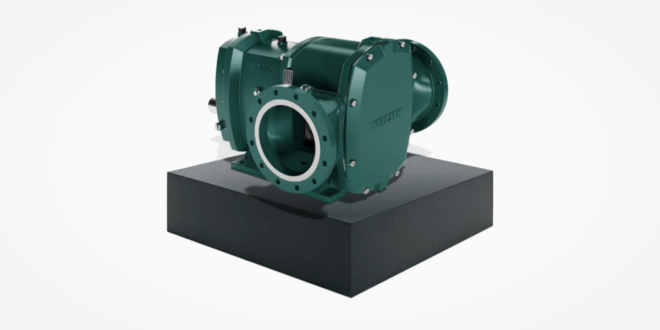

NETZSCH Pumps USA introduces the TORNADO T1 XXLB-F Rotary Lobe Pump, a new high-performance model engineered for demanding, large-scale pumping applications. With flow rates up to 6160 GPM (1,400 m³/h) and differential pressures up to 174 psi (12 bar), the XXLB-F extends the TORNADO® line into new territory, offering maximum flow in a compact, modular, and service-friendly design.

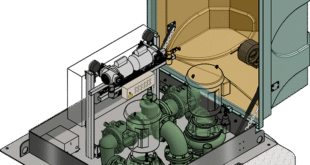

The XXLB-F retains the core strengths of the T1 Generation F platform while expanding capabilities for high-volume applications such as wastewater treatment, biogas, membrane filtration, tank depots, pulp mills, refineries, and more. Available in three sizes (XXLB 2F, 4F, and 6F), the new model delivers up to 35% more flow than previous T1 pumps, while maintaining excellent energy efficiency and dry installation flexibility.

The pump features a one-piece, flow-optimized housing and improved lobe geometry for enhanced volumetric efficiency and gentle handling of shear-sensitive or solids-laden media. New wider lobe tips reduce backflow, while the axial and optional radial wear plates available in highly abrasive- and chemical-resistant materials extend wear life even in harsh operating environments.

Serviceability remains a hallmark of the TORNADO line. The XXLB-F includes Full Service-In-Place (FSIP) access, enabling all wetted parts lobes, wear plates, and seals—to be replaced from the front without removing the pump from the piping. The modular design minimizes wear parts and simplifies seal customization with options including single, double, and API-compliant cartridge seals.

The XXLB-F also features the proven NETZSCH Gearbox Security System (GSS), an innovative air-gap barrier between the mechanical seal and gearbox that prevents fluid ingress, protecting gears and bearings from contamination and enabling predictive maintenance. This robust separation helps avoid catastrophic failure in the event of seal wear and reduces total cost of ownership.

Other key advantages of the XXLB-F include high suction capability (self-priming without external vacuum devices), consistent flow across varying back pressures, reversible flow direction, and mobile configurations for emergency or rural installations. Combined with up to 25% higher energy efficiency, this makes the XXLB-F a highly economical choice for complex pumping challenges.

Ideal for use in environmental, energy, chemical, and industrial markets, the TORNADO T1 XXLB-F handles a broad range of media, from sludge, biogas slurry, and paint to cooked starch, fuels, and molasses, making it a flexible solution for both new systems and retrofit projects.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer