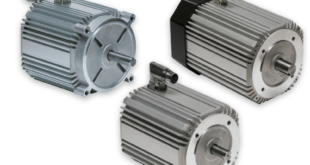

Kollmorgen introduces the AKME Series of hazardous location servo motors with ATEX and IECEx global certification for use in locations that require Zone 2 and Zone 22 ratings. Built on the proven performance, quality and reliability of the AKM servo motor platform, the AKME series allows machine builders to achieve new standards of compact, versatile performance in environments involving ignitable gases or dusts, where their choices have been limited until now.

To suit a wide range of application requirements, AKME servo motors are available in IEC frame sizes 2-7 to work with drives powered by 48, 75 Vdc, 120, 240 or 400 Vac, speeds up to 5,000rpm. The series supports a wide range of feedback options, including resolver, SFD-M, ComCoder, EnDat, Hiperface and BiSS B options. The motors are also ideally matched with AKD, AKD2G and Kollmorgen Essentials (KED) servo drives to deliver optimum torque density, responsiveness and precision in a complete, feature-rich motion solution.

Certified for hazardous environments

The AKME series joins Kollmorgen’s existing portfolio of motors for hazardous environments with extensive global certifications. It has earned ATEX certification under the European Union safety standard for equipment used in potentially explosive environments, including gas Zone 2 and dust Zone 22 locations. It has also earned IECEx certification under the global standard that ensures the safety of equipment and personnel in explosive atmospheres, as established by the International Electrotechnical Commission (IEC).

These certifications make AKME servo motors a strong fit for applications found in pharmaceutical production, food processing, grain elevators, industrial paint booths, and other settings where ignitable gases or dusts may be encountered.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer