Global engineering technologies company, Renishaw, worked with engine manufacturing company Cobra Aero, based in Michigan, USA, to optimise its design processes for aircraft and motorcycle engines.

After working with Renishaw to develop new manufacturing processes, Cobra Aero invested in the AM 400 system to increase its additive manufacturing (AM) capabilities.

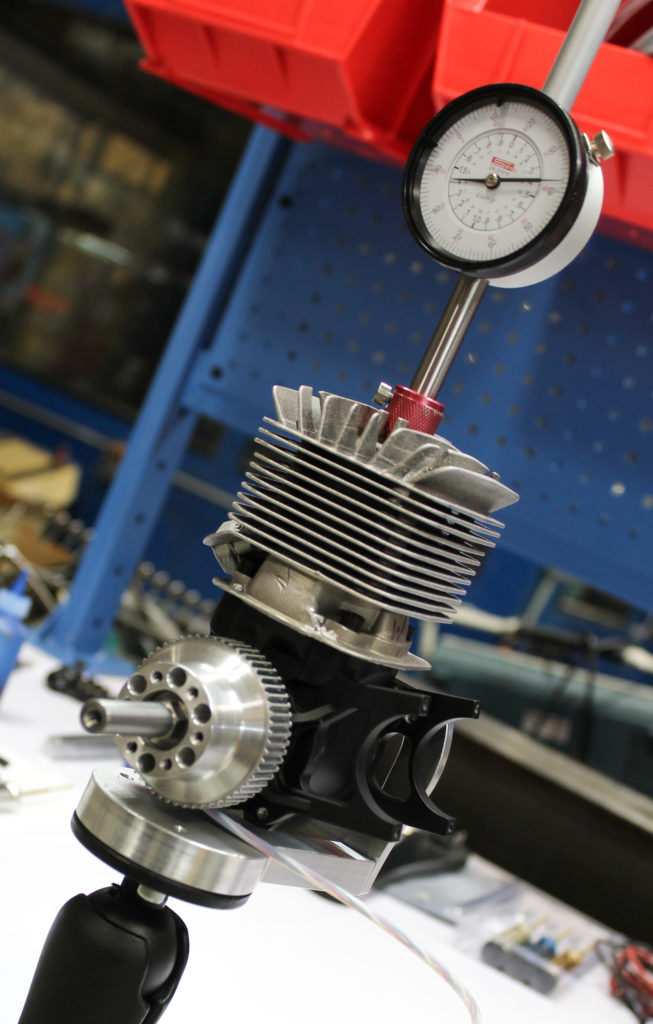

To optimise the design of its engine cylinders, Cobra Aero worked with Renishaw to gain expertise in AM.

The company visited a Renishaw Additive Manufacturing Solutions Centre, USA, and collaborated with Renishaw engineers to use AM to improve the design of a cylinder for an unmanned aerial vehicle (UAV).

Using AM technology allowed Cobra Aero to design a lattice structure to increase airflow, it also allowed them to produce one solid, lightweight part.

“Staying at the cutting edge of manufacturing is important to Cobra Aero,” explained Sean Hilbert, President of Cobra Aero. “Investing in AM allows us to develop tools and new products for high value, small volume applications, speed up the manufacturing process and produce designs that would not be possible using conventional subtractive machining.”

“We decided to redesign the cylinder because of its importance in an engine,” continued Hilbert. “Design changes to this part of the engine must happen rapidly and it is also a high value part, which is why we have chosen to additively manufacture this component. Improving the performance of the cylinder will also improve the overall performance of the engine.”

“By using metal additive manufacturing, Cobra Aero was able to design a part that was unique to the application,” explained Stephen Anderson, AM Business Development Manager at Renishaw Inc. “By using our laser powder bed fusion technology, Cobra Aero was able to produce a single part with complex lattice structures that performs better than conventional component manufacturing techniques.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer