Intertronics has added three products to its extensive range of thermally conductive adhesives from its partner Polytec PT.

Users will benefit from convenient side-by-side cartridge packaging, which simplifies application. The adhesives have added functionality, including high thermal conductivity (2.2 W/mK), very good adhesion, flexibility and high temperature resistance.

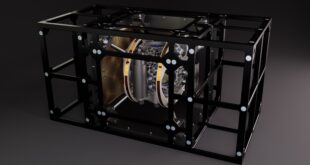

When used as a bonding technique, thermally conductive adhesives fasten components to create a durable mechanical connection, while enabling heat to transfer from the warmer component to the colder component.

Thus, in many cases, thermally conductive bonding, in particular with epoxies, is an alternative to conventional connection processes such as soldering, welding or mechanical attaching.

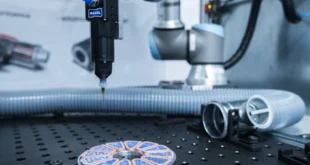

The processing of two-component systems is often a challenge in practice. On the one hand, the mixing ratio of resin and hardener must be kept as accurate as possible. On the other hand, both components must be sufficiently mixed to ensure proper curing of the material.

In order to address the inherent challenges when processing two-component materials manually, Polytec PT has developed a range of thermally conductive adhesives that are available in side-by-side cartridges.

Both components of the adhesive are already filled in the correct mixing ratio and can be easily dispensed by means of a dispensing gun. Resin and hardener mix automatically in the attached static mixer.

The adhesives are ceramic-filled and thus electrically insulating, two-component products which cure at room temperature. If desired, the cure can be accelerated by heat. The variants differ in their thermal conductivity, temperature resistance and their mechanical properties.

Polytec TC 406 is characterised in particular by its high thermal conductivity and mechanical strength. Polytec TC 411 is a flexible thermally conductive adhesive that is able to compensate for thermo-mechanical stress and also adheres well to difficult-to-bond plastic surfaces.

Polytec TC 422 has a very good adhesion especially to metallic surfaces and a high temperature resistance.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer