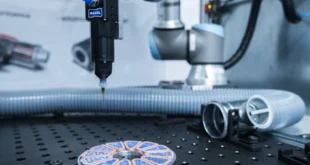

The new modular Apiro motion system from igus, enables design engineers to develop low-cost automation systems with endless possibilities.

Consisting three lubrication-free worm gears for standard, inverted and linear movements, which can be connected in series or parallel and configured to perform simple linear motion to complex robotic tasks.

The worm gears of the Apiro series are made of tribopolymers, which are lubrication- and corrosion-free, as well as chemical resistant.

The engineering plastics ensure a high degree of stability, are light weight, and provide a long, maintenance-free service life. Three different gear ratios are offered: 1:4, 1:32 and 1:64.

To complete the system, mounting brackets, profiles, chainflex cables, motor kit with dryve D1 controller and assembly tools are also available.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer