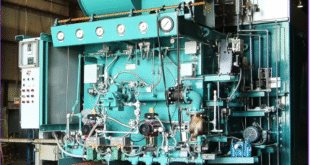

The newly-launched TCX 4-90A is Atlas Copco’s first process cooling chiller range, with plans to introduce more new products to the market in 2021 and extend the range to include higher cooling capacities.

The TCX 4-90A Process Cooling Chiller range features a compact, all-in-one water chiller with an air-cooled condenser and integrated hydro module (onboard tank and pump solutions), with units available in a variety of sizes. TCX chillers are specially designed for cooling water (or a mixture of water and glycol) for a wide range of industrial segments including machine cooling, plastics, printing, food and beverage, medical and pharmaceutical.

Over the past year, Atlas Copco leveraged its more than 140 years of design experience to deliver an innovative chiller product with a wealth of service features and built-in connectivity. The Elektronikon Mk5 Touch controller comes standard on the 11 to 90kW TCX models, putting control at the user’s fingertips.

Additionally, SMARTLINK 24/7 monitoring is available as part of the chiller’s total package. The TCX range can also be covered on a single-service contract with all other Atlas Copco mechanical equipment, such as air compressors, dryers, nitrogen generation systems and low-pressure blowers.

The new range fully complies with Ecodesign directive 2021 to reach the highest level of energy-saving whilst reducing production costs and maximising efficiency, delivering the reliability and performance customers expect and demand from an Atlas Copco product.

The design of the TCX range’s state-of-the-art microchannel condensers requires 30% less refrigerant, making the units more environmentally friendly.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer