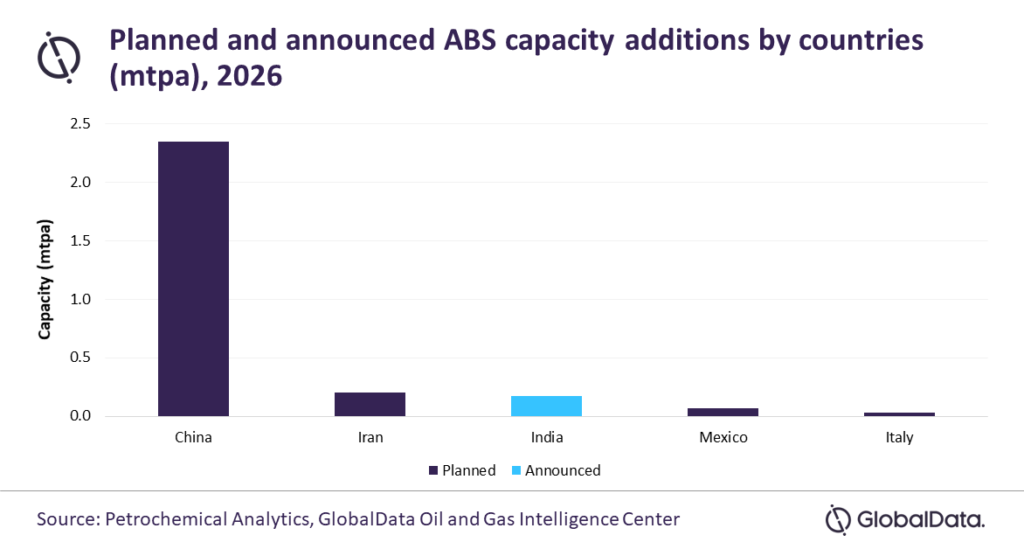

China is set to register the highest acrylonitrile butadiene styrene (ABS) capacity additions in Asia between 2022-2026, due to the growing demand for the low-cost thermoplastic polymer from the country’s automobile manufacturing sector, which is the world’s largest. The country will account for about 93% of the region’s ABS capacity additions by 2026, estimates GlobalData, the data and analytics company.

GlobalData’s latest report, Acrylonitrile Butadiene Styrene Industry Installed Capacity and CapEx Forecast by Region and Countries including details of All Projects, 2022-2026, reveals that China will gain a capacity of 2.35 million tonnes per annum (mtpa) from five planned projects to lead the capacity additions in the region.

Himani Pant Pandey, Oil and Gas Analyst at GlobalData, comments: “In China, a significant capacity addition would be from planned projects that include INEOS Styrolution Ningbo ABS Plant 1, Jilin Petrochemical Company Jilin ABS Plant 4, and Shandon Yulong Petrochemical Longkou ABS Plant with a capacity of 0.60mtpa each. The projects are expected to commence production of ABS in 2023, 2022, and 2025 respectively.”

The second highest ABS capacity additions in China will come from the planned Lihuayi Group Dongying ABS Plant, which will have a total capacity of 0.40mtpa by 2026. The plant is expected to commence operations by 2022.

Himani concludes: “With a capacity of 0.15mtpa, the Zhangzhou CHIMEI Chemical Zhangzhou ABS Plant is the third largest contributor to the capacity additions in the country. The plant is expected to commence production of ABS by 2022.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer