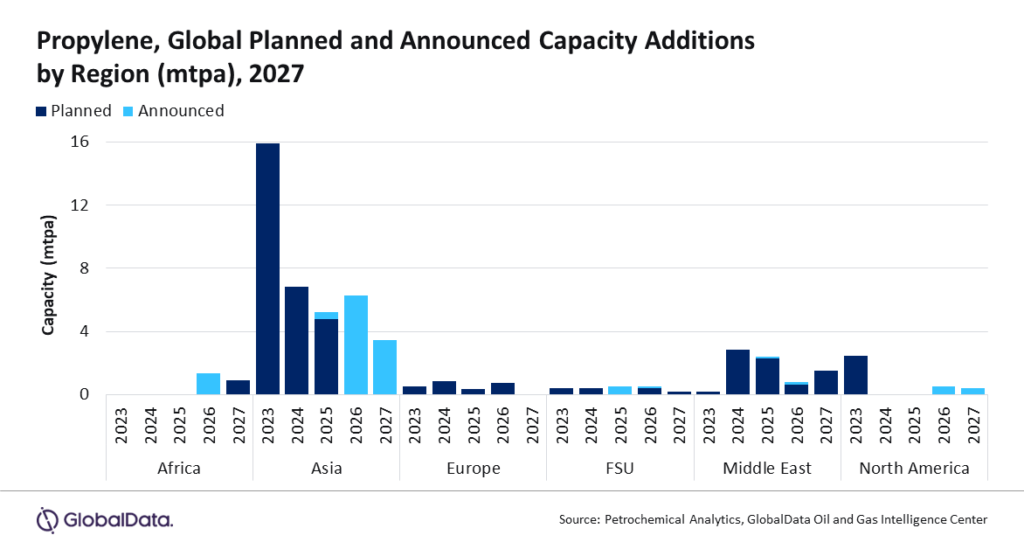

Asia is set to lead the global propylene industry capacity additions with a share of 68.8% by 2027, by gaining capacities from new-build and expansion projects between 2023 and 2027, according to GlobalData, the data and analytics company.

GlobalData’s latest report, Propylene Industry Installed Capacity and Capital Expenditure (CapEx) Market Forecast by Region and Countries including details of All Active, Planned and Announced Projects to 2027, shows that the total propylene capacity of new-build and expansion projects in Asia is expected to be 39.76 million tonnes per annum (mtpa) by 2027. Increased usage of propylene in sectors such as textile, petrochemicals and construction are the key factors for the growth of the propylene industry in Asia.

Nivedita Roy, Oil and Gas Analyst at GlobalData, comments: “For the upcoming new build projects, the region is expected to add a capacity of 39.44mtpa from 65 planned and announced projects, whereas, for the expansion of the existing Propylene projects, the region is expected to add a capacity of 0.32mtpa from five planned projects.”

China and India are the key countries in Asia in terms of propylene capacity additions. The main capacity addition in China will be from a planned project, Shandong Yulong Petrochemical Longkou Propylene Plant 1, with a capacity of 2.30mtpa. It is expected to commence production of propylene in 2024.

Nivedita concludes: “In India, the main capacity will be from an announced project, Reliance Industries Jamnagar Propylene Plant 3, with a capacity of 1.50mtpa. It is expected to come online in 2026.”

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer