Fabian Fischer explains the challenges food and packaging machinery pose for drive and automation solutions and how these can be overcome. Functional safety concepts, for example, are of particular importance.

Food and packaging applications are characterised by harsh environmental conditions. In many cases, the machines are cleaned with aggressive washing substances and high pressure. Motors, frequency inverters and controllers must therefore be robust and hard-wearing. The circuit boards in the current series of drive controllers from KEB Automation are equipped with a protective lacquer specially developed for these environments. HMI control panels from KEB are made from stainless steel and are protected to IP69K. High pressure cleaning and even temperatures up to 50°C do not affect the devices. Performance is also important: food and packaging machines must ensure precise cutting, dosing, mixing and filling in the shortest of cycle times. For this purpose, KEB offers compact, energy-saving, dynamic drives with high overloads and precise control.

Functional safety from drives

Up to now, safety technology was often set up decentrally with external safety modules. These were expensive, complex to wire and required space in the control cabinet. KEB builds functional safety concepts in a smart way. Functions such as Safe Torque Off (STO) or Safely-Limited Speed (SLS) are integrated in the COMBIVERT range of drive controllers and can be selected on a modular basis. Wiring is not required if a safety controller with, for example, Safety over EtherCAT or PROFIsafe is used. With many speed-based safety functions, the safe encoder can even be eliminated. With KEB’s integrated safety function Safe Door-Lock Control (SDLC) door switches on food processing machines with knife drives, for example, are only released when the knife has come to a standstill. An external module for monitoring is not necessary.

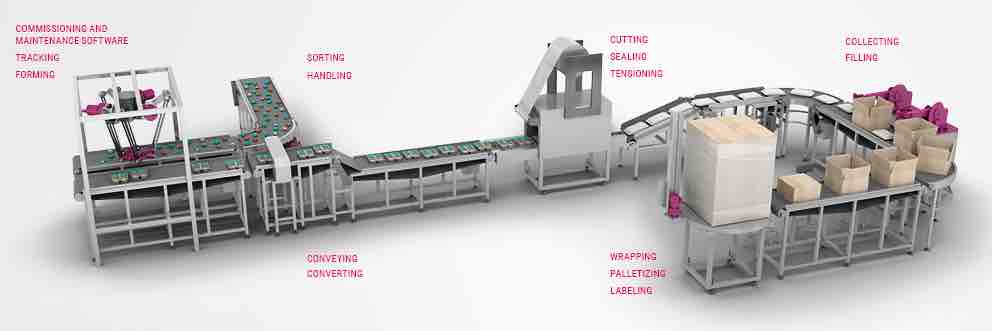

Complete system solutions

From HMIs, controls and drives, to motors, brakes and clutches, KEB implements drive solutions from a single source. Individual components are optimally matched to each other, resulting in maximum machine efficiency. As, for example, the motor and drive controller harmonise perfectly, KEB also complies with the new IE2 energy efficiency label according to the EN 61800-9-2 standard. Another advantage for the machine builder is that there is only one contact person required for all matters concerning the drive. The flexibility of interfaces to components from third-party suppliers is retained in all this, in order to integrate components effortlessly into existing system

Fabian Fischer is Team Leader Application Sales at KEB Automation.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer