With climate change intensifying droughts and reducing freshwater availability, population growth placing increasing pressure on existing resources, and industrial demands pushing water consumption to new heights, global water scarcity has emerged as one of the most pressing challenges of our time

According to a 2024 United Nations report (1), roughly half of the global population currently experiences severe water scarcity for at least part of the year, with around a quarter facing ‘extremely high’ levels of water stress. For many regions, traditional freshwater sources such as rivers, lakes, and aquifers are no longer sufficient to meet the needs of growing communities and economies.

A timely solution

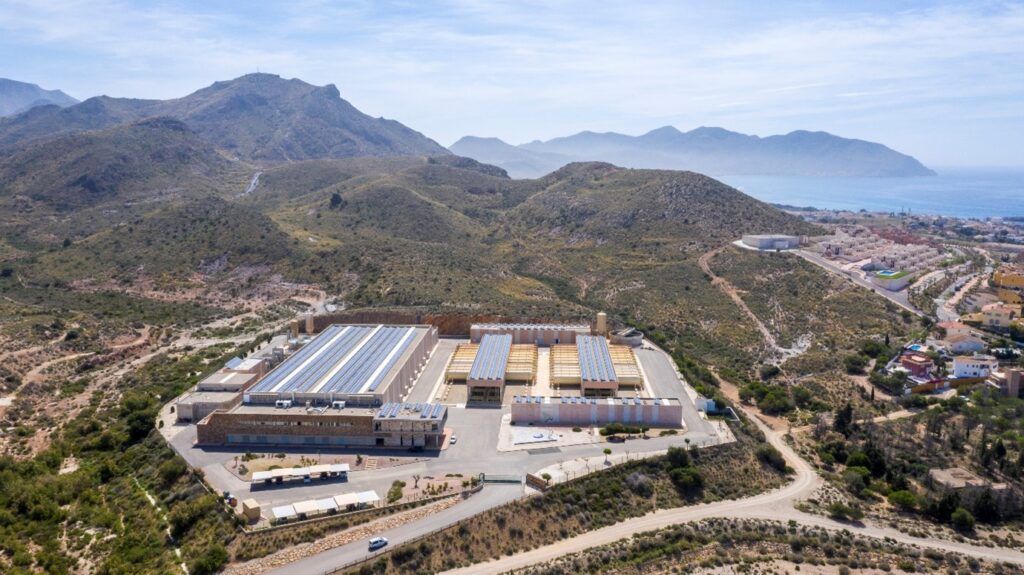

Desalination—the process of converting seawater into freshwater — has become an essential solution for tackling this problem. As such, the global desalination market is now expanding at a rate of more than 9% annually (2), with demand projected to grow significantly, driven by the urgent needs of water-scarce regions such as the Middle East, North Africa, and parts of Asia.

There are several different desalination technologies available, but over recent years reverse osmosis (RO) has become the most widely adopted method worldwide. By forcing seawater through semi-permeable membranes to separate, RO desalination provides an effective and scalable solution capable of delivering millions of gallons of fresh water every day. Its flexibility makes it suitable for both large-scale municipal plants and smaller industrial applications.

However, despite decades of incremental improvements making RO more efficient than ever, there’s no denying the fact that it is still an energy intensive activity. For the operators of these plants, and for their customers, efficient, reliable high-pressure pumps and process equipment play a crucial role in minimizing their energy consumption and the final cost of the supplied water.

The desalination journey

The route from seawater to freshwater in a reverse osmosis (RO) desalination plant is a sophisticated, multi-stage process that relies on advanced engineering to ensure efficiency, reliability, and environmental sustainability.

Step 1: Seawater intake

The first step in the desalination process involves drawing seawater from the ocean through carefully designed intake structures. These structures are engineered to minimise environmental impact, preventing large debris, sand, and marine life from entering the system and damaging downstream equipment. The efficiency and reliability of this initial stage are critical, as any disruptions can cause costly operational issues.

Sulzer plays a decisive role in this stage by supplying a range of high-efficiency pumps specifically designed for seawater intake in reverse osmosis applications. The key products include vertical turbine pumps (VTPs) and axially split case pumps, each tailored to meet different intake requirements.

These pumps are engineered to withstand the harsh marine environment and continuous operation under demanding conditions. They are constructed from corrosion-resistant materials, such as duplex or superduplex stainless steel, which provide excellent resistance to chloride-induced corrosion and biofouling, ensuring that the need for replacements and maintenance is kept to a minimum.

Step 2: Pre-treatment

Once the seawater enters the plant, it undergoes pre-treatment to remove suspended solids, sand, biological materials, and other impurities that could damage or clog the RO membranes. This stage is crucial for ensuring the longevity and efficiency of the membranes, which are sensitive to fouling and scaling. Effective pre-treatment not only protects the membranes but also enhances the overall efficiency of the desalination process.

Nordic Water, a Sulzer brand, supplies advanced sand filters that efficiently remove particulates from the seawater, ensuring that only clean water reaches the membranes. To further enhance water quality, Sulzer’s Chemtech division can supply static mixers where chemicals such as flocculants, coagulants, and biocides are evenly distributed throughout the water, optimizing the removal of contaminants. These mixers are able to deliver minimum pressure drop and effective mixing in a small footprint.

Throughout the pre-treatment process, the pumps maintain optimal flow rates at required pressure and efficiency, ensuring the continuous and stable operation of the plant. They will also provide the minimum required pressure towards high pressure pump and Energy Recovery Devices. By keeping the flow consistent, these pumps help minimize the risk of operational disruptions and maximize the efficiency of downstream processes.

Step 3: Reverse osmosis

Once the seawater has been pre-treated, it enters the actual RO stage — the heart of the desalination process. In this phase, seawater is pressurized and forced through semi-permeable membranes that effectively separate salts from the water.

The membranes allow only water molecules to pass through, while the remaining concentrated brine —rich in removed salts — is discharged for safe disposal. This stage is highly energy-intensive, accounting for a significant portion of a desalination plant’s operational costs, making energy efficiency and precise pressure control critical to the process.

Sulzer plays a pivotal role in optimising this phase by supplying high-pressure feed pumps. These are engineered to deliver the consistent, high-pressure flow required to push seawater through the RO membranes and typically account for more than half of a desalination plant’s power consumption. This makes Suzer’s ability to provide reliable, efficiency pumps a key element of running an effective operation.

In some desalination plants, a second pass of RO membranes is introduced to further refine the quality of the final product water. This additional stage ensures that the desalinated water meets even the most stringent purity standards, particularly for industrial or specialized municipal use. To support this, Sulzer supplies dedicated second pass pumps, designed to maintain the necessary pressure and flow for this additional membrane filtration phase.

In addition, Sulzer can supply booster pumps to help integrate energy recovery devices (ERDs) into the RO process to significantly improve energy efficiency. ERDs capture the hydraulic energy from the high-pressure brine reject stream and transfer it back to the incoming seawater.

Step 4: Post-treatment

After the RO membranes have filtered out the salts and impurities, the water is not quite ready to drink or use in industry just yet. Without essential minerals, it can taste flat or even slightly acidic, and over time, that acidity can cause corrosion in pipes and storage systems. That’s why post-treatment is so important—it helps balance the water’s composition, making it safer, more stable, and better-tasting.

In order to eliminate any acidity, carbon dioxide (CO₂) must be introduced following reverse osmosis and prior to remineralisation. Sulzer’s specialised static mixers play a crucial role in this process by efficiently dissolving CO₂ gases directly into the water stream and ensuring thorough mixing within the main line. This innovative approach eliminates the need for dedicated CO₂ dosing or injection systems, simplifying the overall process and reducing the operational complexity.

At this stage, minerals like calcium and magnesium are added to improve the taste and ensure chemical stability. By fine-tuning the post-treatment process, Sulzer helps desalination plants deliver fresh, high-quality water that’s ready for municipal, agricultural, or industrial use — while also protecting the systems that distribute it.

Many companies supply individual pieces of equipment for desalination, but Sulzer stands apart as a full-line supplier — offering everything from intake to distribution. With a seamlessly integrated portfolio of pumps, filters, mixers, and maintenance services, Sulzer ensures that every stage of the desalination process works efficiently and reliably together. Few companies can match its ability to deliver a complete, end-to-end solution for desalination plants.

In addition to its equipment portfolio, Sulzer provides a range of support services that help plants maintain peak performance over the long term. Long-term service agreements (LTSAs) are available for critical equipment like high-pressure and booster pumps, covering scheduled annual maintenance and offering rapid field service response — typically within 24 to 72 hours, depending on site location and technical needs.

Sulzer also plays a key role in retrofit projects, particularly as more operators replace maintenance-heavy Pelton turbines with modern, energy-efficient ERDs. In other cases, changes in plant operating conditions have prompted the need for updated hydraulic components to match new duty points—challenges Sulzer’s engineering teams are well equipped to address.

To support more reactive maintenance needs, Sulzer offers spare parts and corrective services when issues arise, helping restore pumps to their original performance with minimal disruption.

Desalination is constantly evolving, with each new project pushing the boundaries of efficiency, reliability, and scale. Every year, the industry finds new ways to make the process smarter, more sustainable, and more cost-effective.

Sources:

(1) https://www.unwater.org/publications/un-world-water-development-report-2024

(2) https://www.cognitivemarketresearch.com/water-desalination-plants-market-report?srsltid=AfmBOoqJppFJq_SO4yMnd7619aFnsnm_EazAhVtz_K_6wJ8yM_pDaOZb

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer