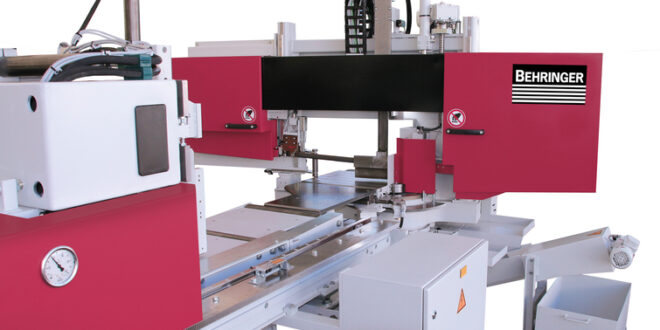

Allie Klipp spotlights the resurgence of bandsaws in metal fabrication, where shops rely on precise, consistent cutting of structural steel, tubing, and specialty alloys. Modern bandsaws equipped with servo-driven feed systems, intelligent controls, and vibration-dampening cast iron frames help fabricators achieve cleaner cuts, faster throughput, and reduced scrap

In an era dominated by laser precision and robotic automation, one might assume that a tool invented in the 19th century would be on its way out. Yet bandsaws are making a notable comeback in modern manufacturing as people realise their indispensability for case-specific usage.

From cutting high-performance alloys to reducing material waste, bandsaws are proving themselves more relevant than ever. Their evolution from simple manual machines to precision-engineered, digitally optimized systems reflects the changing needs of today’s metalworking industry and the enduring value of a cutting solution well-matched to its application.

A return rooted in application

While technological advancements in modern metalworking, such as waterjets and lasers, often receive significant attention, their practicality can be limited depending on their application. Factors such as cost, material compatibility, and operational constraints all play a crucial role in selecting the appropriate tool for the job.

The resurgence of bandsaws is primarily driven by their versatile applications. Bandsaws are exceptionally well-suited for cutting large-dimension, high-hardness materials that are often too thick for alternative cutting methods. As manufacturers increasingly utilise specialised steels with microstructures and properties sensitive to high temperatures, bandsaws provide a cost-effective and practical solution, delivering superior performance where other cutting technologies are less effective.

Bandsaws also produce less waste. Compared to waterjet or laser cutting, bandsaws remove less material per cut and allow for chip recovery, which reduces scrap and supports recycling measures. By capturing and reusing metal chips, manufacturers can reintroduce scrap into the production cycle, reducing raw material demand and supporting more sustainable manufacturing practices. In production environments where regulatory pressures are mounting and gases for plasma cutting are expensive, the bandsaw offers a practical, environmentally conscious solution.

Precision, sustainability and the pursuit of efficiency

Today’s manufacturers are chasing tighter tolerances, faster throughput, and greener operations. Bandsaw technology has evolved accordingly. Modern models offer a high level of cutting precision that minimizes the need for secondary operations. Additionally, advanced variable frequency drives (VFDs), servo motors, and control systems now enable accurate positioning, programmable feed rates, and optimized blade pressure; all of which reduce material loss and make for a more consistent, high-quality output.

Greater cutting precision directly reduces the need for downstream processes, allowing manufacturers to streamline production. This level of accuracy translates into meaningful savings, not just in time, but also in energy consumption and material usage. Precision also supports better sustainability practices. By tightening tolerances and improving chip collection, manufacturers can recycle materials and cut down on waste, hitting both economic and environmental goals.

Dispelling the ‘just a saw‘ myth

A persistent misconception in the industry is that a saw is ‘just a saw’. This mindset often leads companies to invest in lower-quality bandsaws, which can become significant sources of inefficiency and unnecessary expense. A low-performance saw introduces a variety of inefficiencies; it increases material waste, shortens blade life, and introduces inconsistencies and inaccuracies that have a ripple effect throughout the production line.

Material handling plays a critical role in the overall efficiency of a sawing operation, yet it’s often overlooked. For instance, high-speed miter saws can cut quickly, but if the surrounding workflow, like part loading and unloading, cannot keep up, that speed advantage is lost. To fully benefit from fast cutting technologies, machines must be integrated into a well-coordinated material flow that prevents bottlenecks and maintains consistent throughput.

Technological milestones in bandsaw evolution

The evolution of bandsaw technology has been shaped by both tool and machine development. Early machines were unable to keep up with emerging blade capabilities, but that gap has closed dramatically in recent years.

Key milestones in this space include the introduction of bimetal and carbide-tipped blades, which extended blade life and allowed cutting of harder materials. Additionally, the development of SC (speed cutting) technology paired with high-pressure coolant systems enabled consistent, cooler cuts across a wider range of materials. Meanwhile, advancements like servo technology and vibration-dampening cast iron frames have improved the overall cut quality and machine durability.

On the production floor, these advancements translate to faster cut times, longer blade life, and fewer interruptions due to maintenance or tool changes. Operators spend less time adjusting settings or compensating for inaccuracies, and more time running efficient, repeatable cuts. The improved durability and stability of modern machines also reduce the risk of rework, scrap, and downtime, helping manufacturers meet tighter deadlines, improve part quality, and lower overall cost per cut.

Where early bandsaws were manual or semi-automatic, today’s models feature intelligent control systems and automated feed regulation, transforming them into sophisticated, highly adaptable production tools. These advancements have repositioned the bandsaw from a basic cutting tool to an integral part of modern machining workflows capable of delivering the precision, consistency, and adaptability required in today’s high-demand manufacturing environments.

Automation meets sawing

Though robotics are increasingly used in manufacturing, their role in bandsawing is application-specific. While robotics are valuable for multi-step processes like stacking or deburring, they’re not always the most efficient choice for straightforward cutting operations. In many cases, a well-automated bandsaw can outperform a robotic cell in both speed and efficiency when the task is limited to precise, repetitive cuts.

This shift toward smart automation is reflected in systems like the Automatic Feed Control Pro (AFC Pro), developed by BEHRINGER Saws. BEHRINGER engineered AFC Pro to streamline cutting without overcomplicating the process. The system adapts cutting parameters in real time, reducing operator input while improving consistency. The result is fewer errors, longer blade life, and higher-quality cuts across a range of materials.

BEHRINGER was among the first to implement servo-driven technology in bandsaws and developed the AFC Pro system, which remains unrivalled in the industry. Looking ahead, one of the company’s innovations is BehrConnect, a digital platform that enables remote machine monitoring and diagnostics. This advancement further bridges the gap between traditional machinery and the requirements of Industry 4.0.

Today’s bandsaws are more than just cutting tools, they are intelligent systems designed to adapt to the evolving needs of modern manufacturing. With features that support digital integration and address challenges like skilled labor shortages, these machines are built to communicate, connect, and optimize performance in increasingly complex production environments.

A technology built for what’s next

As the metalworking industry evolves, bandsaws are proving not only resilient but essential. Their adaptability, low cost of operation, and material efficiency make them ideal for a manufacturing landscape shaped by complex materials and high-performance demands.

Future innovations will likely focus on digital connectivity, smarter controls, and improved integration into automated production environments.

In an era defined by high-tech alternatives, the resurgence of the bandsaw is not a matter of nostalgia but a response to necessity. This time-tested tool is now redefining its role, establishing itself as an indispensable asset in modern manufacturing and shaping the industry’s next chapter.

Allie Klipp is Business Manager, BEHRINGER Saws.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer