Stephen Lincks explains how a custom approach to circulation heater design can dramatically improve process efficiency, reliability, and system longevity. By examining factors like watt density, fluid dynamics, and CAD-driven design, he shows how tailored heater design enhances safety, efficiency, and long-term reliability

In process heating applications ranging from heating water and oil to air and specialty gases, electric circulation heaters are trusted for their efficiency and precision. However, not all heaters are created equal. Selecting the right solution requires more than simply checking boxes on a spec sheet. The design decisions made at the start of a project can determine whether your heater delivers years of seamless operation — or leads to premature failure, fluid degradation, and costly downtime.

For engineers and specifiers, the key to long-term success lies in working with a heater manufacturer that understands how to tailor the heater’s design to its application, including the unique demands of oil and gas process conditions. That’s where some manufacturers excel, offering deep expertise in electric heat and custom design capabilities that ensure your circulation heater performs safely, efficiently, and reliably.

Why Watt density matters

One of the most critical variables in heater design is watt density, or the amount of heat output per unit surface area of the heating element. Get it right and you are rewarded with energy-efficient heating and long service life. Get it wrong and you risk burning out heating elements, damaging the process fluid, or reducing the system’s overall efficiency.

If the watt density is too high for a given application, fluids can carbonise or chemically break down. In more extreme cases, the heater’s elements can overheat and fail prematurely. While standard heaters may work in simple heating jobs, most process applications require more nuanced design thinking. For example, heating chocolate, high-pressure gases, oil pipeline fluids, or cryogenic fluids all present vastly different challenges and therefore demand different heater configurations.

Circulation heaters also play a key role in the oil and gas industry, where they are used for crude oil processing, natural gas conditioning, and heating pipeline fluids. Applications include maintaining optimal temperatures for oil viscosity, preventing hydrate formation in natural gas lines, and supporting enhanced oil recovery operations. In oil pipeline heating and turbine lube oil applications, these heaters ensure precise fluid temperatures for efficient transport and processing, reduce the risk of thermal shock in critical equipment, and maintain optimal oil flow characteristics — resulting in improved throughput, reduced energy consumption, and minimized wear on pumps, compressors, and other oil and gas machinery.

Specifying the right circulation heater begins with a clear understanding of the application’s operating conditions. Key considerations include the minimum and maximum fluid flow rates, operating pressure, and outlet temperature. Equally important are the thermal properties of the fluid itself — such as its specific heat, viscosity, thermal conductivity, and maximum allowable sheath temperature for the heating element. When these parameters are taken into account during the design phase, the resulting heater is far more likely to meet performance requirements while also protecting the integrity of the fluid, minimizing maintenance needs, and extending the service life of the equipment.

The hidden power of fluid dynamics

How fluid moves through a circulation heater dramatically affects heat transfer. In most cases, turbulent flow — where the fluid undergoes constant velocity fluctuations and mixing — is ideal. That’s because turbulence helps move heat away from the element quickly and evenly, reducing the risk of hotspots. Hotspots occur when localised areas on the heating element surface become significantly hotter than the surrounding fluid due to inadequate heat dissipation. These elevated temperatures can lead to a number of problems: they may cause fluid breakdown, accelerate scale buildup, and dramatically shorten the life of the heating element itself. Encouraging turbulent flow through smart design helps prevent these issues by ensuring that heat is consistently carried away from the element and distributed evenly throughout the process fluid. In oil pipeline and separator heating applications found in oil and gas processing, turbulent flow improves temperature uniformity and helps prevent hydrate or paraffin buildup.

Laminar flow, by contrast, is slower and smoother, characterised by parallel layers of fluid moving at consistent velocities with minimal mixing between them. This orderly motion results in a thin boundary layer around the heating element where heat transfer occurs. Because there’s limited fluid movement near the element’s surface, heat is not carried away as efficiently, which can lead to localised overheating and reduced system performance. In theory, laminar flow develops fully only after the fluid has traveled a certain distance in a straight, uninterrupted path. But in practice, most electric heat exchangers are relatively compact and include internal components like support spacers or baffles that disrupt the flow. As a result, the smooth, consistent motion needed for true laminar flow rarely has a chance to form. Instead, the fluid movement inside a circulation heater is typically a mix of flow types, influenced by the system’s size, geometry, and internal structure.

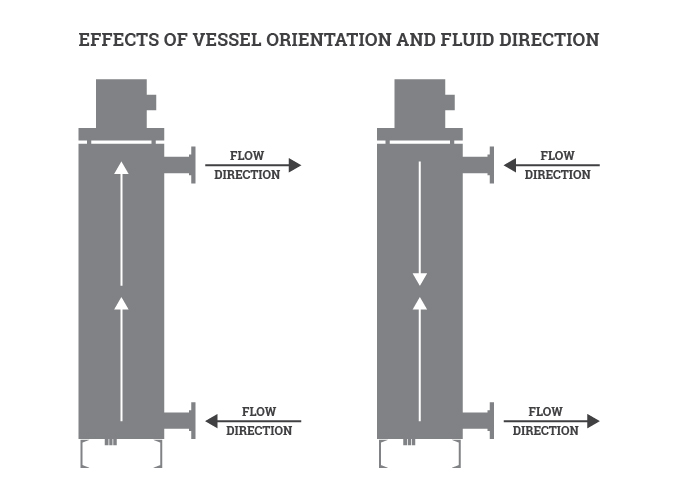

Most real-world applications do not fall neatly into either fully laminar or fully turbulent flow — they exist in what is called the transition flow range. In this middle ground, fluid behavior can be unpredictable, shifting between smooth and chaotic movement depending on changes in pressure, temperature, or flow rate. That is why it is so important for heater design to account for more than just the basic heating requirements. A well-designed circulation heater considers the physical orientation of the vessel (whether it’s mounted vertically or horizontally), the direction of fluid flow, and internal components like baffles or support spacers. These design choices help shape the way the fluid moves through the heater. For example, by encouraging turbulence at key points in the flow path, designers can improve heat transfer and prevent problem areas like hotspots. Ultimately, these small design adjustments can make a big difference in how evenly and efficiently the fluid is heated, especially in complex oil and gas operating environments.

Smart geometry and design tools

Today’s best heater manufacturers rely on powerful computer-aided design (CAD) software to simulate the complex interactions between heat, pressure, and fluid flow within a system. These digital tools allow engineers to model exactly how a heater will perform under real world operating conditions before a single component is built. For example, CAD simulations can show what happens during startup when fluid flow is just ramping up, or how the system behaves under full load during peak operation. This kind of analysis is especially valuable for identifying potential problem areas early, such as uneven heating, excessive pressure drop, or zones where fluid might stagnate.

One of the biggest advantages of CAD modeling is the ability to balance heat transfer with pressure drop, a critical factor in gas heating applications. As gases are heated, their properties change — pressure, viscosity, and thermal conductivity all shift in response to temperature. At higher pressures, these changes can be significant. If designers fail to account for them, it can result in heaters that either underperform or operate outside safe parameters.

Additionally, radiant heat emitted from the heating elements themselves must be considered, especially in gas applications where excessive radiant heat can damage surrounding components or cause unexpected temperature spikes.

By using CAD tools to explore different design scenarios and optimize key variables, manufacturers can create heaters that are not only efficient and reliable, but also tailored to the unique demands of each application, including those found in oil and gas production and processing. This kind of precision engineering helps ensure that the final product performs exactly as intended — delivering consistent heat, protecting the process fluid, and operating safely within system limits.

Heater design is a process, not a product

Designing an effective circulation heater is not just about choosing the right specs from a catalog. It is a collaborative process that takes into account every aspect of the heating system — from the properties of the process fluid to the physical layout of the installation. This is why it is so important to work with a manufacturer that brings both thermal expertise and application knowledge to the table. Indeeco offers a wide range of customisable heaters built to meet complex process requirements. Their team works closely with customers to evaluate process conditions, simulate performance, and tailor every heater to the demands of the application, ensuring reliability, efficiency, and long-term performance from day one.

Custom circulation heaters outshine off-the-shelf solutions

In industrial environments where precision, safety, and efficiency are non-negotiable, the circulation heater you choose can have lasting impacts on your process outcomes and your bottom line. While off the shelf heaters might seem convenient, they often overlook the critical variables that define real world performance: fluid properties, flow dynamics, operating pressures, and system geometry. That is why a thoughtful, application-specific approach to heater design matters. By collaborating with a manufacturer who understands the complex relationship between thermal performance and process requirements, engineers, facility managers, and OEMs can ensure not only reliable heat but also greater control, energy savings, and system longevity. Whether you are operating in food processing, petrochemicals, manufacturing, or a specialised industrial niche, the right heater manufacturer can help you turn your heating challenges into safe, efficient solutions built to perform from day one and optimized for the long haul.

Stephen Lincks is Vice President of Engineering at Indeeco.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer