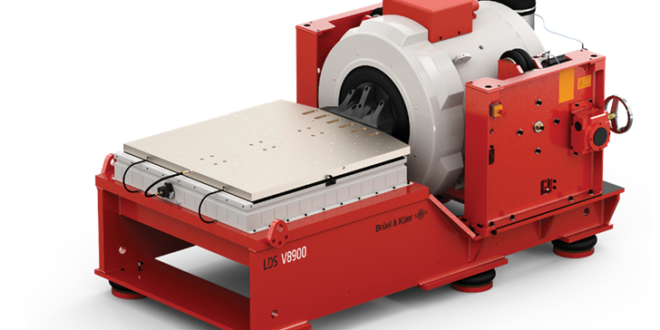

Bruel &Kjaer is a leader in acoustic and vibration test and measurement products used by the space, aerospace, defence, automotive, telecoms and mining industries and the contract marks a diversification for Blackhill.

Nick Woods, Category Manager, Bruel & Kjaer VTS Ltd, said: “As a company that looks for more than just the price of the products we buy, finding Blackhill Engineering was an ideal fit with our business requirements.

“Not only do they have the fabrication and machining capability we were looking for, they have the right mind set to give their customers the confidence they know what they are talking about.

“This culture exists from the beginning of the ordering process, through every touch point during manufacture to the final delivery of product.

“With the support we have seen to date, Bruel & Kjaer VTS Ltd. is confident in the knowledge it has found a long-term business partner.”

The base frames weigh up to 2.5 tonnes and relate to eight different models of vibration test equipment, of which each model has up to six different

versions.

Blackhill Engineering has one of the largest CNC mills in the South West of England and boasts one of the region’s largest crane lifts with the capability to lift up to 50 tonnes.

Its 28,000 square foot of workshop space offers the flexibility to build large and small components and prototypes and perform one-off, low rate bespoke and continuous volume production.

Dan Baker, Business Development Manager at Blackhill Engineering, said: “Working with Bruel & Kjaer is a major diversification in Blackhill’s portfolio and an exciting milestone in its 60 year history”.

Blackhill’s markets have spanned nuclear new build and decommissioning, civil engineering & construction, marine & offshore, oil & gas, renewables, quarrying & mineral processing, space & telecommunications and automotive.

Recent projects have included flood gates and the delivery of components totalling 650 tonnes of steel for the Hinkley Point C jetty, for which it won two EDF Energy HPC Excellence Awards for Best Local/Regional Business and Best Manufacturing Equipment Supplier.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer