Floor drains are one of the most overlooked sources of contamination in food and beverage facilities. Viking Kristjansson explains why regulators are scrutinising drainage design more closely than ever and offers a practical framework for specifying hygienic, high-performance systems that reduce risk and long-term liability. For architects, engineers, and plant managers, it is a timely look at how smarter drainage design can protect both food safety and the bottom line

When it comes to food and beverage facilities, the risks posed by floor drains demand far more attention than they often receive. Far from a background detail, drains are active breeding grounds for bacteria that spread from the dark, damp conditions beneath our feet.

Industry investigations have shown that a large share of contamination incidents can be traced back to drains and floor areas, making them a persistent weak point in many food plants. Think of these spaces like laboratories where dangerous bacteria can flourish if left unchecked.

To protect product quality and consumer safety, sanitary drains must be treated with the same urgency as any piece of food-contact equipment or conveyor in production lines. The issue goes beyond compliance and calls for a fundamental shift in mindset.

Drains are essential equipment.

In the wake of the Food Safety Modernization Act and heightened FDA and USDA scrutiny, regulators are looking more closely at how hygienic performance is designed into facility infrastructure, not just processing equipment. When a contamination event is traced back to an underperforming drain, owners and specifiers can face serious operational and legal consequences, so treating drains as commodity hardware is increasingly a risk management liability rather than a cost-saving measure.

Whether planning a new facility, addressing failing or outdated drainage systems, or taking on expansions and repurposing projects, thoughtful selection and design of drains are critical for upholding strict hygiene standards and safeguarding operations. For architects, engineers, and facility managers, these decisions shape not only immediate productivity but also the long-term safety and reliability of the entire facility.

This article presents an expert framework for evaluating drainage solutions, so you can make the right choices from project design to daily maintenance. Let’s elevate how we think about drains, and dramatically reduce the risk that they become the weak link in your facility’s food safety chain.

Understanding your facility’s drainage requirements

Effective drainage starts with a deep understanding of your facility’s distinct operations. Every type of food and beverage plant, and every zone within it, has unique needs dictated by the specific processes in play.

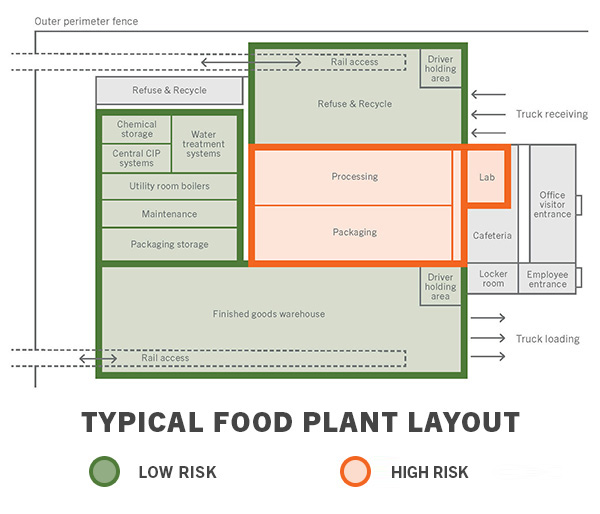

For example, meat processing, brewing, and dairy operations each place very different demands on drainage, ranging from high solids to hot liquids to large volumes of low-viscosity effluent. Drainage needs also vary by zone within a single facility. These zones can be categorized by risk level from a hygiene perspective.

Low-risk zones, such as storage areas for packaged goods, typically have minimal drainage requirements, whereas high-risk zones, which include processing and washdown areas, have the most stringent demands. These areas require robust drainage systems built to withstand frequent, high-pressure cleaning and manage significant volumes of liquids and solids, regardless of the facility type.

A one-size-fits-all approach to drainage is simply not sufficient. Instead, specifiers must thoroughly assess what is produced, processed, or cleaned in each area to determine the most appropriate drainage solutions.

Key considerations include:

- Type of Production: The processes being performed, whether it is high-moisture operations like beverage bottling or dry ingredient handling, demand tailored drainage strategies. For example, raw protein areas require greater solids handling capacity, while dairy and bakery spaces may have different flow and hygiene requirements.

- Volume and Nature of Waste: Assess the expected waste load. Will there be significant amounts of product particulates, fats, oils, and greases, or mostly liquids? Defining these parameters is crucial for selecting drain size, type, and configuration.

- Chemical and Thermal Exposure: Many production lines discharge hot, acidic, or caustic effluents as part of cleaning or processing cycles. The drainage system and surrounding materials must withstand repeated thermal shock and chemical exposure.

- Operational Load Ratings: In areas with heavy equipment traffic, such as forklift routes or pallet staging zones, drains must be engineered to withstand high mechanical stress.

- Future Cleaning Processes: Understanding future cleaning processes, specifically Clean-in-Place (CIP) cycles and Standard Operating Procedures (SOPs), is essential to ensure the drainage system remains compatible with sanitary and operational requirements. Specifiers should verify not only how equipment will be cleaned, but where CIP discharge and washdown effluent will go, so high-solids slurries do not simply accumulate on the floor or overwhelm undersized drains.

Designing efficient layouts

Beyond understanding requirements, the physical layout of the drainage system dramatically impacts both initial costs and long-term operation and durability. Strategic design focuses on minimizing complexity while maximizing performance.

Reducing Concrete Slopes: Ideally, drainage layouts are planned to limit the amount and angle of slopes that concrete contractors must install. Excessive sloping complicates construction and increases costs, so trench drains should be positioned and coordinated with equipment flows to keep gradients manageable for workers and heavy equipment.

Minimizing Piping Length and Complexity: Shorter, simpler runs of drainage piping are critical because excessive, complex networks drive up cost and make it harder to maintain proper slope for effective drainage.

Avoiding Inaccessible Buried Lines: Deep, inaccessible buried piping presents a major operational risk because inadequate pitch leads to stagnant water and frequent clogs. Minimizing the underground “footprint” reduces blockage risk and simplifies maintenance.

Maximizing Access and Flow: Locate drains to capture flow at the source and create direct, unobstructed paths to the main discharge, improving cleaning efficiency and eliminating stagnant sections where bacteria can thrive.

Selecting the optimal type of drain

Match the drain type to its application. While slot drains offer easy cleanability, area drains and grated drains may be better suited for high-volume flow or heavy debris locations.

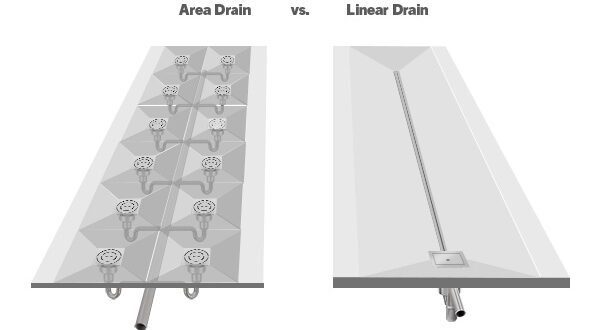

Traditional area drain systems present significant challenges due to their extensive underground piping, which is nearly impossible to access and clean. In a typical 4,800-square-foot production space, a traditional area drain layout can easily result in more than 200 feet of buried piping.

These hidden pipes are difficult to inspect or clean, allowing contaminants and solids to accumulate and reduce flow.

Linear drain systems, on the other hand, are specifically designed to reduce the need for extensive underground piping, making drainage channels significantly easier to access for cleaning and maintenance. In a comparable layout using a 100‑foot slot drain, the underground network can often be reduced to only a short main connection run, simplifying inspection and ongoing maintenance.

Area drains demand a costly and complex four-slope floor design around each drain. In our example, this requires a total of 48 individual slopes, compared to only four for a linear drain system. Besides the higher construction costs and added complexity, this design creates uneven floor surfaces, reducing both efficiency and safety for workers and wheeled equipment.

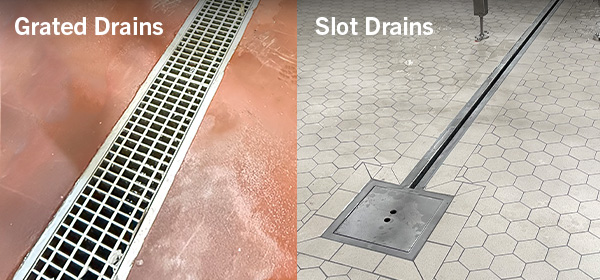

There are two types of linear drains: drains with grates and slot drains.

Grated drains have several drawbacks. Their grates trap bacteria, which causes odors and contamination risks. Cleaning them is a time-consuming process involving heavy, cumbersome grates, and the uncovered drains pose safety risks that lead to costly production downtime. Over time, these grates can rust and warp, creating tripping hazards and damaging wheeled equipment.

Slot drains offer a better solution with a sleek, single-slot design that eliminates bulky grates. They minimize bacterial buildup, simplify cleaning, enhance safety, and improve aesthetics.

Choose a well-engineered drainage system

Once the overall layout is determined, the focus shifts to the drains themselves. Modern sanitary drains are engineered with specific features that minimise risk and maximise longevity. Key attributes of a well-designed drain include:

- Superior Materials: Stainless steel is the industry standard for a reason. It is non-porous, corrosion-resistant, and can withstand aggressive cleaning chemicals and temperature fluctuations, making it the ideal material for hygienic environments.

- Hygienic Design: Every aspect of the drain should be designed to eliminate harborage for bacteria. This means smooth, rounded corners and seamless welds. Any crevice, pit, or sharp angle can trap moisture and food particles, creating a biofilm hotspot that is nearly impossible to clean. These principles mirror the hygienic design expectations embedded in standards such as 3-A Sanitary Standards, NSF, and EHEDG, which are recognised as the leading global frameworks aimed at minimizing bacterial harborage points across both food-contact and non-food-contact equipment.

- Pre-sloped Construction: Drains should feature a built-in slope that ensures a positive flow toward the outlet. This prevents standing water, a primary contributor to microbial growth and foul odors. Pre-sloped trench drains simplify installation and guarantee effective drainage from day one.

- Designed for Easy Cleaning: A sanitary drain must have smooth, accessible surfaces for simple maintenance. Unlike traditional grates that can trap bacteria and warp over time, slot drains eliminate safety hazards and streamline sanitation. Modern slot drain designs eliminate internal obstructions, enabling effortless cleaning along the entire channel. When paired with flexible brushes and automated wash-down systems, these drains help sanitation crews clean far more quickly and effectively. From a specification standpoint, it is critical to confirm that drain designs can be cleaned within normal sanitation windows and integrate with CIP and SOP practices, rather than relying on ad‑hoc workarounds.

Precise installation: the critical link

Even the best drain design will fail without precise installation. Two factors are critical: the drain’s slope and the interface between the drain and the surrounding floor.

As previously emphasized, a proper slope is essential to prevent water pooling, which can cause hygiene risks and structural damage. Properly sloped, pre‑engineered drain systems eliminate manual guesswork, reduce installation time, and ensure a sanitary environment.

Equally critical is the connection between the drain and the floor. This interface must be structurally and chemically robust; any gaps or cracks create a dangerous breeding ground for bacteria that is nearly impossible to eliminate and can lead to structural failure.

Many failures stem from incorrect sizing, inadequate load ratings, or improper installation and floor tying, so specifiers should call for contractors with proven experience installing hygienic drains in food and beverage environments, not just generic plumbing credentials. Partnering with manufacturers that work through a vetted installer network, covering drains, concrete, and floor coatings as a unified scope, can significantly reduce performance risk and streamline project delivery.

GDT Food Safe Drains ensures a hygienic, durable bond through several proven methods:

- KeyForm Channel Detail: For new construction, GDT uses a temporary cover during the concrete pour to form a keyed channel along the drain edge. This creates a thicker, mechanically interlocked band of floor coating at the perimeter rather than a thin, fragile edge that can easily crack under thermal or mechanical stress.

- Engineered Coating Thickness: The keyed design ensures extra coating thickness where the floor meets the stainless steel. This durable transition is better equipped to withstand thermal shock, heavy traffic, and rigorous cleaning cycles.

- Stainless Surface Pretreatment: Stainless steel naturally has a smooth, non-porous surface that resists adhesion. To counter this, GDT’s system includes a specialized pretreatment that enhances the chemical bond between the stainless steel and floor coatings like epoxy or urethane concrete. By modifying the metal’s nano-oxide layer, this process prevents the coating from pulling away over time.

- Co-ordinated Installation Practices: GDT collaborates with its alliance partner network to comprehensively manage every step—from design and excavation to concrete work and drain installation—treating the drain and floor interface as a unified system. This coordinated approach ensures proper installation and allows the entire process to be completed during brief, scheduled production downtimes, such as a single weekend.

These installation and coordination issues are even more acute in renew and retrofit projects, where production often runs 24/7 and shutdown windows are measured in hours, not weeks. In these cases, specifiers must balance improved drainage layouts with constraints such as immovable equipment, limited excavation zones, and the need to sequence drains, concrete, and floor coating work so upgrades can be completed during short, planned outages.

Prioritize your drains, protect your business

It is time to elevate the conversation about drainage systems. They are not simply a passive part of the building; they are a critical component of your food production equipment. By investing in thoughtfully designed, professionally installed systems, you are making a direct investment in food safety, operational efficiency, and long-term success. It is equally important to work with drainage manufacturers who support the specification process with clear performance data, guide specifications, and BIM or CAD models, so hygienic details are fully coordinated in drawings and project documents from the outset.

Facility managers and engineers who prioritize drainage create a safer foundation for their operations. Don’t overlook your drains. Treat them as essential infrastructure and leverage the latest innovations in state-of-the-art systems.

Viking Kristjansson is Vice President Sales Engineering at FoodSafe Drains.

Engineer News Network The ultimate online news and information resource for today’s engineer

Engineer News Network The ultimate online news and information resource for today’s engineer